Therefore, the subsidiaries SAUERESSIG GmbH & Co. KG, UNGRICHT GmbH + Co. KG, Wetzel GmbH, DORNBUSCH Engraving GmbH and Saueressig Design Studio GmbH were merged to operate under one umbrella brand to deliver varied surface solutions. One of the main focuses lies on the field of tissue and hygiene industry. Already the acquisition in 2017 merged the two market-leading companies SAUERESSIG GmbH & Co. and UNGRICHT GmbH + Co. KG and therefore created an internationally unique network for roller production and engraving technologies.

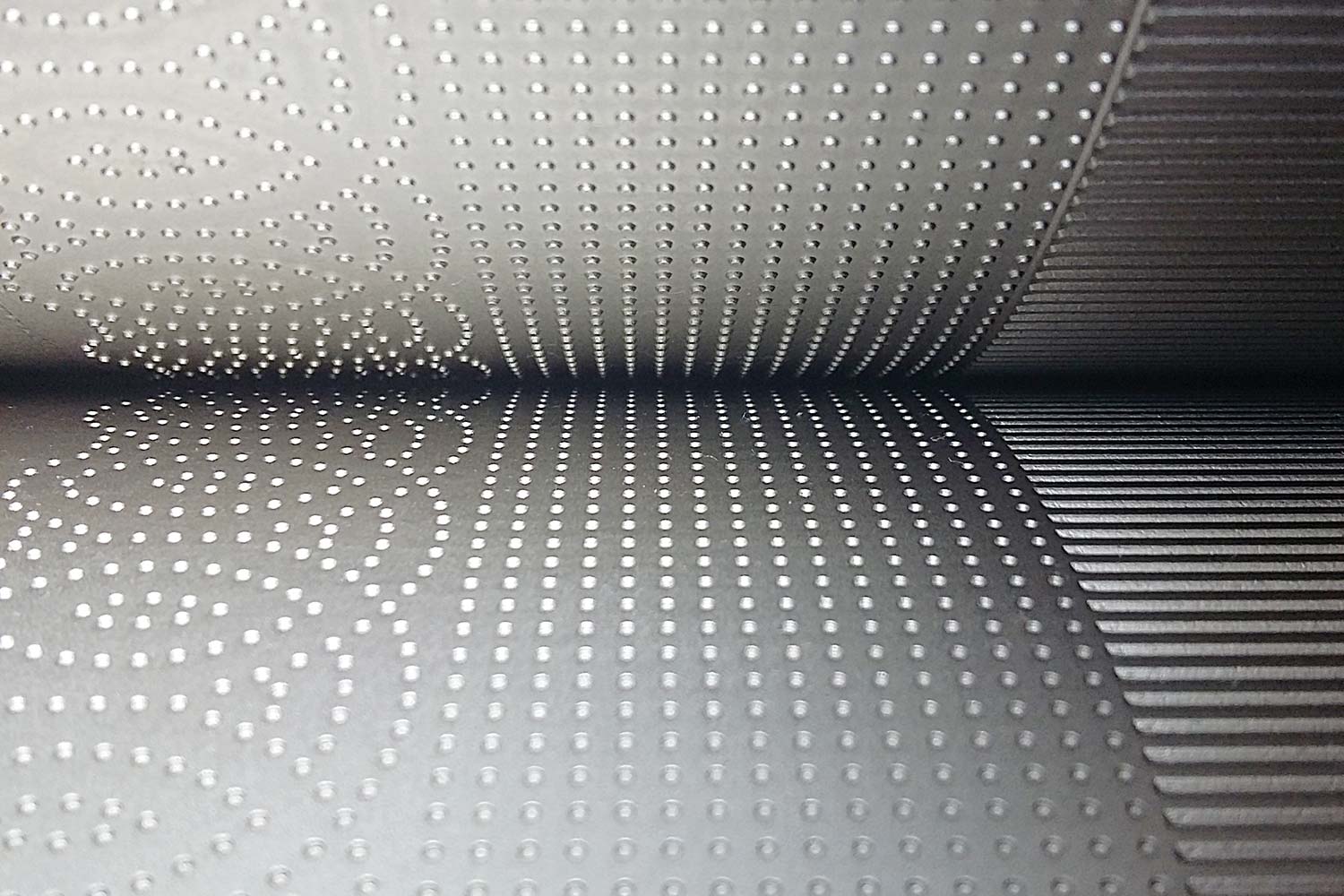

SAUERESSIG UNGRICHT now bundles decades of expert knowledge and comprehensive competencies in internal innovation teams. Thereby a particular focus lies on optimising the engraving process for embossing rollers used in the match steel rollers (union) procedure for folded products such as napkins, handkerchiefs and facial tissue.

With more than 60 years experience, the Company has established itself as a renowned expert in the market

This engraving process is currently carried out using two different techniques: the mechanical process and the wet-chemical process.

And although both have been established in the international production for decades, they have deficiencies the expert wants to avoid in the future. On the one hand mechanical engraving is followed by a hardening process which always involves the risk of hardening distortion. The most common wet chemical process, on the other hand, requires the use of acid, which always involves certain risks. SAUERESSIG UNGRICHT therefore aspires to evolve a process that avoids the risk of hardening distortion, makes the use of aggressive acids unnecessary and eliminates human error. In close cooperation with a manufacturer of laser engraving machines, the experts have now succeeded in developing a new laser unit.

This allows the desired structure to be applied directly on the hardened roller surface of the embossing roller and therefore reduces possible losses of quality. With the further development of this innovative technology SAUERESSIG UNGRICHT wants to make a significant contribution to quality assurance and prospectively set new standards on the international market.

Matthews International GmbH

Within SAUERESSIG Group the Matthews International Corporation is bringing together the business units packaging, surfaces, engineering, rollers and elastomers under a common umbrella brand. As leading international supplier along the pre-press stage as well as of rotogravure and embossing tools, flexographic printing and special machine construction, SAUERESSIG Group offers a comprehensive expertise. The modular product and service portfolio bundles diverse competencies from the fields of design, color management, reproduction, roller and steel core production, cutting and creasing tools as well as special machinery according to customer-specific requirements. SAUERESSIG Group is part of Matthews International Corporation (NASDAQ GSM: MATW). Please visit: www.saueressig.com

Therefore, the subsidiaries SAUERESSIG GmbH & Co. KG, UNGRICHT GmbH + Co. KG, Wetzel GmbH, DORNBUSCH Engraving GmbH and Saueressig Design Studio GmbH were merged to operate under one umbrella brand to deliver varied surface solutions. One of the main focuses lies on the field of tissue and hygiene industry. Already the acquisition in 2017 merged the two market-leading companies SAUERESSIG GmbH & Co. and UNGRICHT GmbH + Co. KG and therefore created an internationally unique network for roller production and engraving technologies.

SAUERESSIG UNGRICHT now bundles decades of expert knowledge and comprehensive competencies in internal innovation teams. Thereby a particular focus lies on optimising the engraving process for embossing rollers used in the match steel rollers (union) procedure for folded products such as napkins, handkerchiefs and facial tissue.

With more than 60 years experience, the Company has established itself as a renowned expert in the market

This engraving process is currently carried out using two different techniques: the mechanical process and the wet-chemical process.

And although both have been established in the international production for decades, they have deficiencies the expert wants to avoid in the future. On the one hand mechanical engraving is followed by a hardening process which always involves the risk of hardening distortion. The most common wet chemical process, on the other hand, requires the use of acid, which always involves certain risks. SAUERESSIG UNGRICHT therefore aspires to evolve a process that avoids the risk of hardening distortion, makes the use of aggressive acids unnecessary and eliminates human error. In close cooperation with a manufacturer of laser engraving machines, the experts have now succeeded in developing a new laser unit.

This allows the desired structure to be applied directly on the hardened roller surface of the embossing roller and therefore reduces possible losses of quality. With the further development of this innovative technology SAUERESSIG UNGRICHT wants to make a significant contribution to quality assurance and prospectively set new standards on the international market.

Products

Calender cylinders, Calenders, Coating machines and plants, Cooling cylinders, Cylinders, Embossing cylinders, Embossing machines, Nickel plating, Paper converting machines, Perforated screen plates, Rolls .