The demand from the tissue market for high-quality products at competitive costs is pushing tissue paper producers to enhance the performance of their continuous machines in terms of annual tons of paper produced. Improving the quality of the paper can be achieved by optimizing machine components that enhance mechanical properties such as strength, elasticity, and softness. On the other hand, productivity increases depend on the tissue machine’s ability to produce more tons of paper within the allotted production time, ideally operating for more days throughout the year and doing so more efficiently. A key indicator widely used to evaluate and measure the performance of a production plant is the Overall Equipment Effectiveness (OEE), which identifies critical areas preventing the plant from reaching its maximum production capacity.

By calculating OEE, maintenance engineering activities can be planned to reduce inefficiencies and production losses. A starting point for increasing and improving production is analyzing and eliminating the Six Big Losses.

Availability

- Unscheduled machine downtimes.

- Set-up times.

Performance

- Micro-stops.

- Cycle times not meeting targets.

Quality

- Scrap and rework.

- Start-up times.

Since the tissue machine is a rather complex industrial plant, only some components contributing to the three main indicators defining OEE will be addressed. Referring to the three key OEE indicators:

- Availability Rate

- Performance Index

- Product Quality Rate

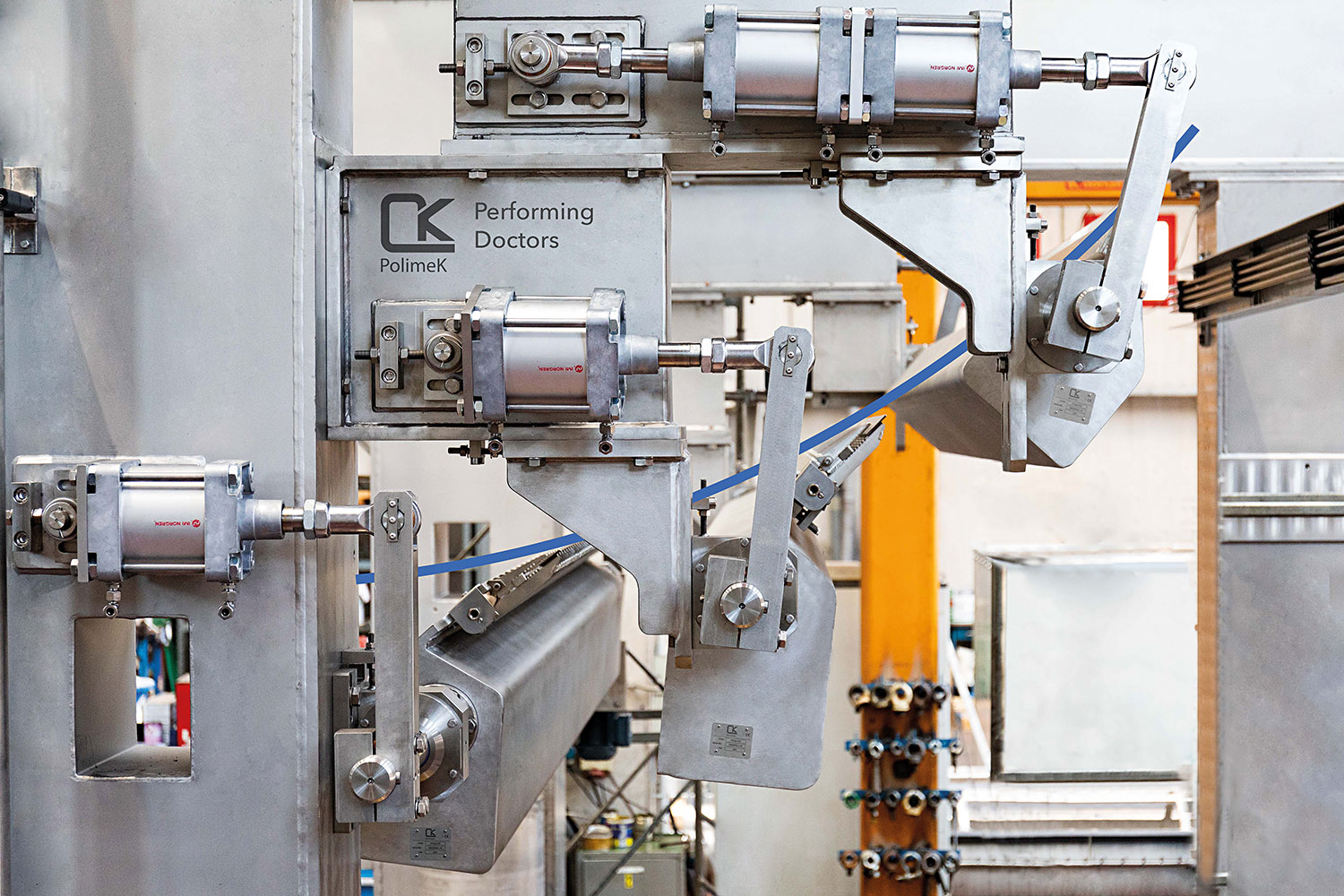

One area of the tissue machine that directly impacts the Six Big Losses is the Yankee section. This is the terminal part of the machine where the paper sheet, pressed between a suction roll and a large heated cylinder (the Yankee cylinder), transitions from a damp, incomplete state to the compact and finished sheet we are used to seeing. The sheet is removed from the Yankee cylinder by means of a hardened steel blade, which is insert in a support known as the creping doctor. The interaction between the creping blade and the Yankee cylinder is directly linked to the OEE index, as extended machine downtimes can occur in this area due to wear and damage to the Yankee coating caused by the blade. The creping blade is applied to the Yankee cylinder with a high linear pressure, around 300 daN/m, necessary to detach the sheet from the cylinder and impart some of its required mechanical properties.

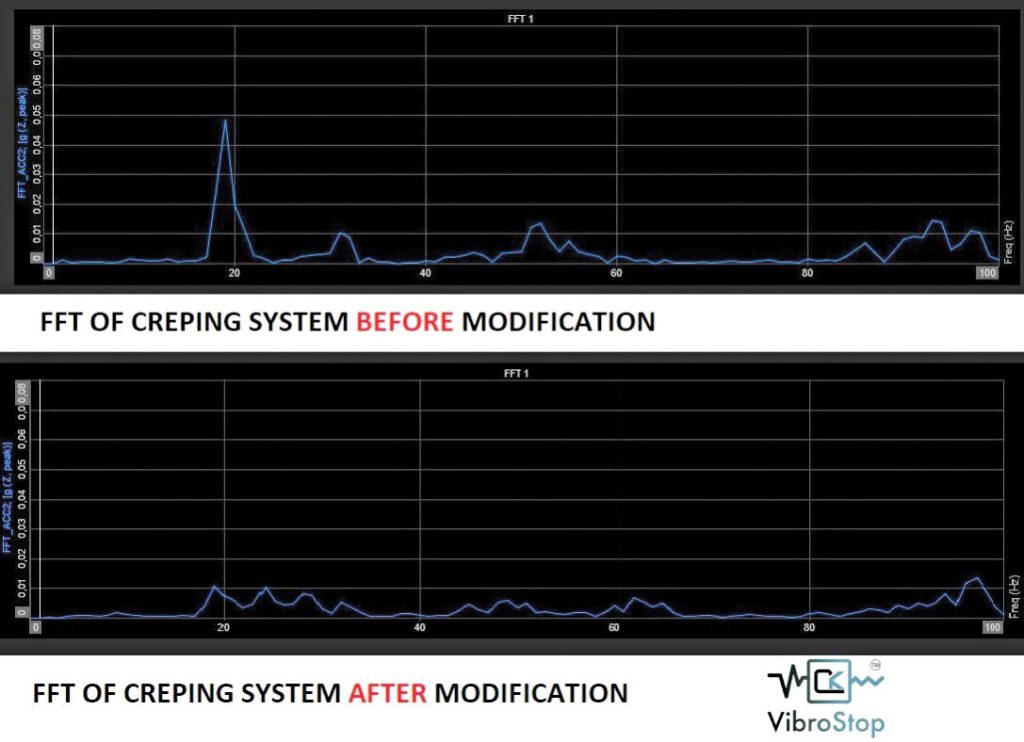

An increase in machine speed to boost productivity or the use of low-quality creping systems can destabilize the creping blade, damaging the surface of the cylinder in a phenomenon known as Chatter Marks. These marks are caused by unwanted vibrations of the creping system, which penetrate through the blade into the cylinder surface, creating longitudinal grooves.

Creping doctor frequency before and after VibroStop™ installation.

Chattermarks on a yankee surface.

A machine downtime of approximately 3-4 days is required to grind the Yankee cylinder back to its standard operating condition, reducing the annual production availability of the machine. Other unscheduled downtimes related to creping systems include micro-stops for the replacement of worn components or to better profile the blade. These unexpected stops reduce the machine’s performance index. Poor creping or the creation of micro-holes in the sheet due to misalignment of the creping blade lowers the product quality rate.

Each installation is perfectly designed and developed to meet the needs of the customer

The issue is resolved by a team of experts in these systems, who realign and properly adjust the creping unit.

POLIMEK, with its team of experts boasting over 30 years of specific experience, manufactures, installs and supplies advanced creping systems suitable for all tissue machines. Polimek’s annual preventive maintenance significantly contributes to improving both efficiency and product quality. To extend the time between Yankee cylinder regrinds and reduce unexpected machine stops due to vibration issues, Polimek has developed an innovative system called VibroStop™, capable of significantly reducing both high and low-frequency vibrations, the latter being related to the inertia of the structures and therefore more dangerous in terms of Chatter Marks. For more information about advanced creping systems, maintenance services or the new VibroStop™ system, please contact Polimek’s technical office.

Doctoring systems specialist, made in Italy