Up to 15% better running times on the machine

The patented, new ANDRITZ design with its increased number of binding points offers improved cross-dimensional fabric stability compared to conventional SSB forming fabric designs. This results in reduced internal fabric wear and allows up to 15% better running times on the machine compared to conventional SSB designs. The improved co-planarity and stable fabric guiding contributes towards achieving stable 2-sigma paper profiles during the entire fabric running cycle. New monofilament material compositions and the changed top fabric design reduce fabric wear and enhance energy-saving potentials.

ANDRITZ QSB designs are meanwhile operating successfully in the graphic and packaging paper industries, with numerous installations providing added value to different customer processes.

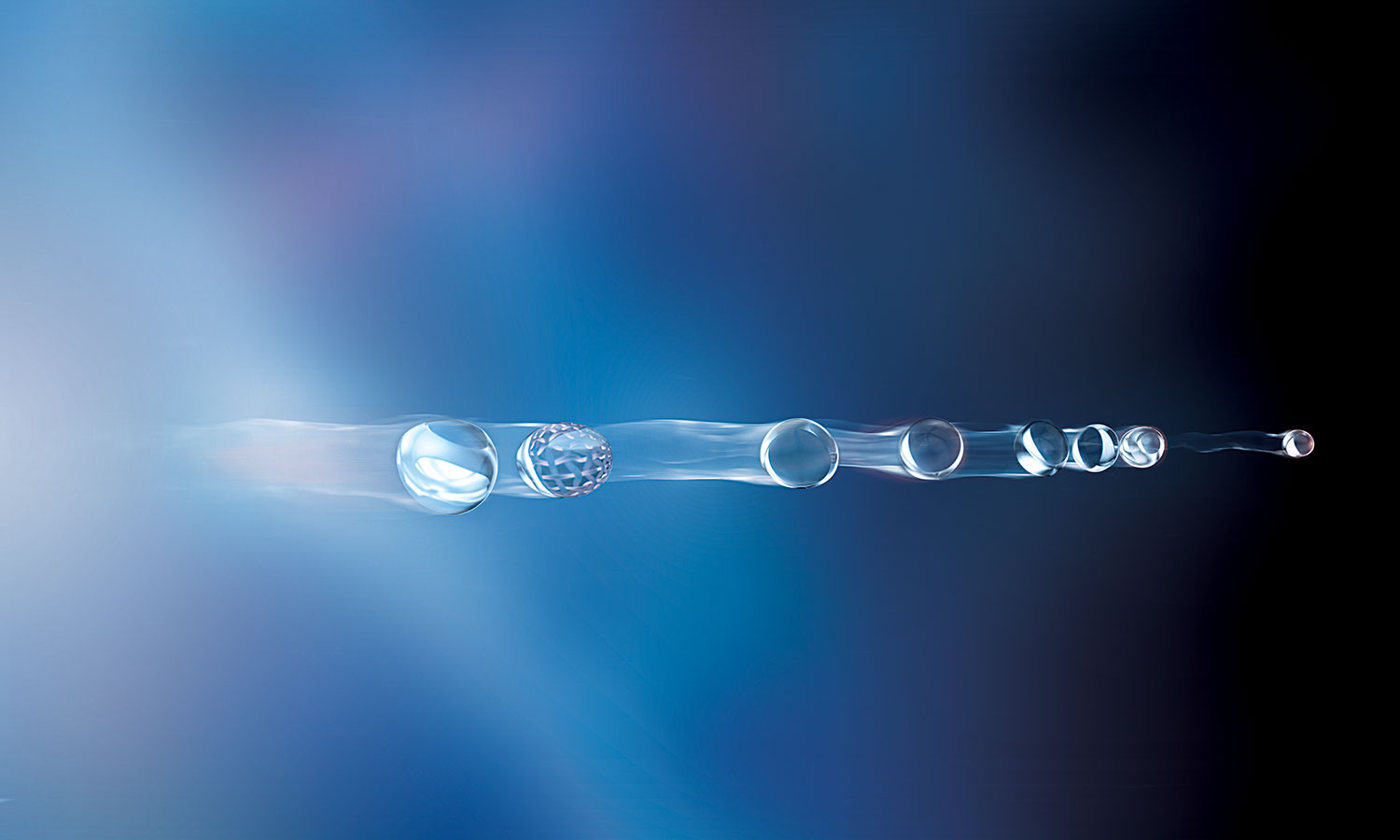

With WeCare PRIME, ANDRITZ has now completed its product series for tissue machine applications. Fabric callipers between 0.60 mm and 0.69 mm enable enhanced fabric surface characteristics with defined dewatering channels for better formation and an effective dewatering process during operation. Machine hygiene improves with the benchmarking of thinner fabric callipers. Patented QSB forming fabric designs from ANDRITZ are available in 2:1 and 3:2 versions for all paper products and former machine designs. The ANDRITZ WeCare PRIME forming fabrics for tissue applications are available in 4-shaft and 8-shaft fabric designs (Figure 1 and Figure 2).

ANDRITZ Kufferath is one of the leading European specialists in the development and manufacture of forming fabrics for the paper industry

WeCare PRIME QSB design – case study

The following case study uses the example of a Crescent Former machine design, as shown in Figure 3.

Operating at 1,750 m/min, the machine has a design speed of up to 2,000 m/min. First results of the WeCare PRIME 4-shaft QSB design in comparison with conventional SSB fabric designs used by a customer in the tissue market: formation improved significantly with the new ANDRITZ WeCare PRIME tissue forming fabric design. There is no marking visible on the tissue product with the new QSB design. The excellent fabric dewatering capabilities resulted in improved tissue product characteristics. This enabled stable production conditions at high machine speeds (Figure 4 and Figure 5).

Machine data and former design

- Former: Crescent Former

- Design speed: 2,000 m/min

- Product: Toilet tissue and paper tissue grades

- Grammage: 15-22 g/m²

- Raw material: 100% pulp and mixed pulp+DIP

- Forming fabrics:

- Conventional fabric designs

- WeCare PRIME 4-shaft QSB Design

- Improvement targets:

- Machine hygiene and performance

- Tissue formation and quality

ANDRITZ tissue forming fabric parameters |

QSB 4-shaft design |

|---|---|

| Machine-side weft diameter [mm] | 0.25 |

| Air permeability [CFM] | 520-560 |

| Calliper [mm] | 0.60 |

| Fibre support index | 173-168 |

| Support points/cm² | 1,229-1,170 |

Summary

With the patented ANDRITZ Kufferath QSB forming fabric design, you can improve both the tissue product quality and the machine performance.

Proven features:

- High dewatering capabilities (air permeability and low fabric callipers);

- Improved tissue quality (FSI >165);

- Clean run and no water spray at high tissue machine speeds;

- Improved cross-dimensional fabric stability for consistent machine operating conditions during the entire running cycle (6 months).

About ANDRITZ Kufferath

ANDRITZ Kufferath is one of the leading suppliers of modern forming fabric and technical wire cloth technology. With production facilities in Düren, Germany, and Levice, Slovakia, the company designs product solutions for various process industries. A major part of the business deals with forming fabrics for pulp as well as for paper machines producing graphical papers, packaging papers, specialty papers, and tissue.

ANDRITZ Kufferath GmbH

ANDRITZ Kufferath is one of the leading European specialists in the development, manufacture and distribution of forming fabrics for the paper industry. ANDRITZ Kufferath strives to meet customers’ expectations by delivering high-quality products, such as TecnoWeave, FormWeave, ARTOS, and other forming fabrics for various applications.

Up to 15% better running times on the machine

The patented, new ANDRITZ design with its increased number of binding points offers improved cross-dimensional fabric stability compared to conventional SSB forming fabric designs. This results in reduced internal fabric wear and allows up to 15% better running times on the machine compared to conventional SSB designs. The improved co-planarity and stable fabric guiding contributes towards achieving stable 2-sigma paper profiles during the entire fabric running cycle. New monofilament material compositions and the changed top fabric design reduce fabric wear and enhance energy-saving potentials.

ANDRITZ QSB designs are meanwhile operating successfully in the graphic and packaging paper industries, with numerous installations providing added value to different customer processes.

With WeCare PRIME, ANDRITZ has now completed its product series for tissue machine applications. Fabric callipers between 0.60 mm and 0.69 mm enable enhanced fabric surface characteristics with defined dewatering channels for better formation and an effective dewatering process during operation. Machine hygiene improves with the benchmarking of thinner fabric callipers. Patented QSB forming fabric designs from ANDRITZ are available in 2:1 and 3:2 versions for all paper products and former machine designs. The ANDRITZ WeCare PRIME forming fabrics for tissue applications are available in 4-shaft and 8-shaft fabric designs (Figure 1 and Figure 2).

ANDRITZ Kufferath is one of the leading European specialists in the development and manufacture of forming fabrics for the paper industry

WeCare PRIME QSB design – case study

The following case study uses the example of a Crescent Former machine design, as shown in Figure 3.

Operating at 1,750 m/min, the machine has a design speed of up to 2,000 m/min. First results of the WeCare PRIME 4-shaft QSB design in comparison with conventional SSB fabric designs used by a customer in the tissue market: formation improved significantly with the new ANDRITZ WeCare PRIME tissue forming fabric design. There is no marking visible on the tissue product with the new QSB design. The excellent fabric dewatering capabilities resulted in improved tissue product characteristics. This enabled stable production conditions at high machine speeds (Figure 4 and Figure 5).

Machine data and former design

- Former: Crescent Former

- Design speed: 2,000 m/min

- Product: Toilet tissue and paper tissue grades

- Grammage: 15-22 g/m²

- Raw material: 100% pulp and mixed pulp+DIP

- Forming fabrics:

- Conventional fabric designs

- WeCare PRIME 4-shaft QSB Design

- Improvement targets:

- Machine hygiene and performance

- Tissue formation and quality

ANDRITZ tissue forming fabric parameters |

QSB 4-shaft design |

|---|---|

| Machine-side weft diameter [mm] | 0.25 |

| Air permeability [CFM] | 520-560 |

| Calliper [mm] | 0.60 |

| Fibre support index | 173-168 |

| Support points/cm² | 1,229-1,170 |

Summary

With the patented ANDRITZ Kufferath QSB forming fabric design, you can improve both the tissue product quality and the machine performance.

Proven features:

- High dewatering capabilities (air permeability and low fabric callipers);

- Improved tissue quality (FSI >165);

- Clean run and no water spray at high tissue machine speeds;

- Improved cross-dimensional fabric stability for consistent machine operating conditions during the entire running cycle (6 months).

About ANDRITZ Kufferath

ANDRITZ Kufferath is one of the leading suppliers of modern forming fabric and technical wire cloth technology. With production facilities in Düren, Germany, and Levice, Slovakia, the company designs product solutions for various process industries. A major part of the business deals with forming fabrics for pulp as well as for paper machines producing graphical papers, packaging papers, specialty papers, and tissue.

address Lommessemstrasse 32-36, 52353, Düren, Germany