How has Maflex been able to succeed during the crisis?

In the past year, the market has changed dramatically. As the away-from-home market struggled and the retail market surged, Maflex was provided with many opportunities to deliver retail lines across the world. Along with supplying machinery for retail bath tissue and kitchen towel, Maflex machinery was also used for the production of wipes and wiper material.

Maflex is in the process of adding more capacity to the headquarters in Lucca, which will nearly double the existing space of the production area, keeping up with the growing demand for equipment. The facility was recently remodeled, creating a modern and efficient workspace.

The North American sales, service, and production facility has been an integral part of the ongoing growth of Maflex and their global presence. North American customers have direct access to local service and sales support.

The facility is utilized for machine rebuilds, group sub assembly, parts distribution, and hands on/classroom training.

What does Maflex attribute to these successes?

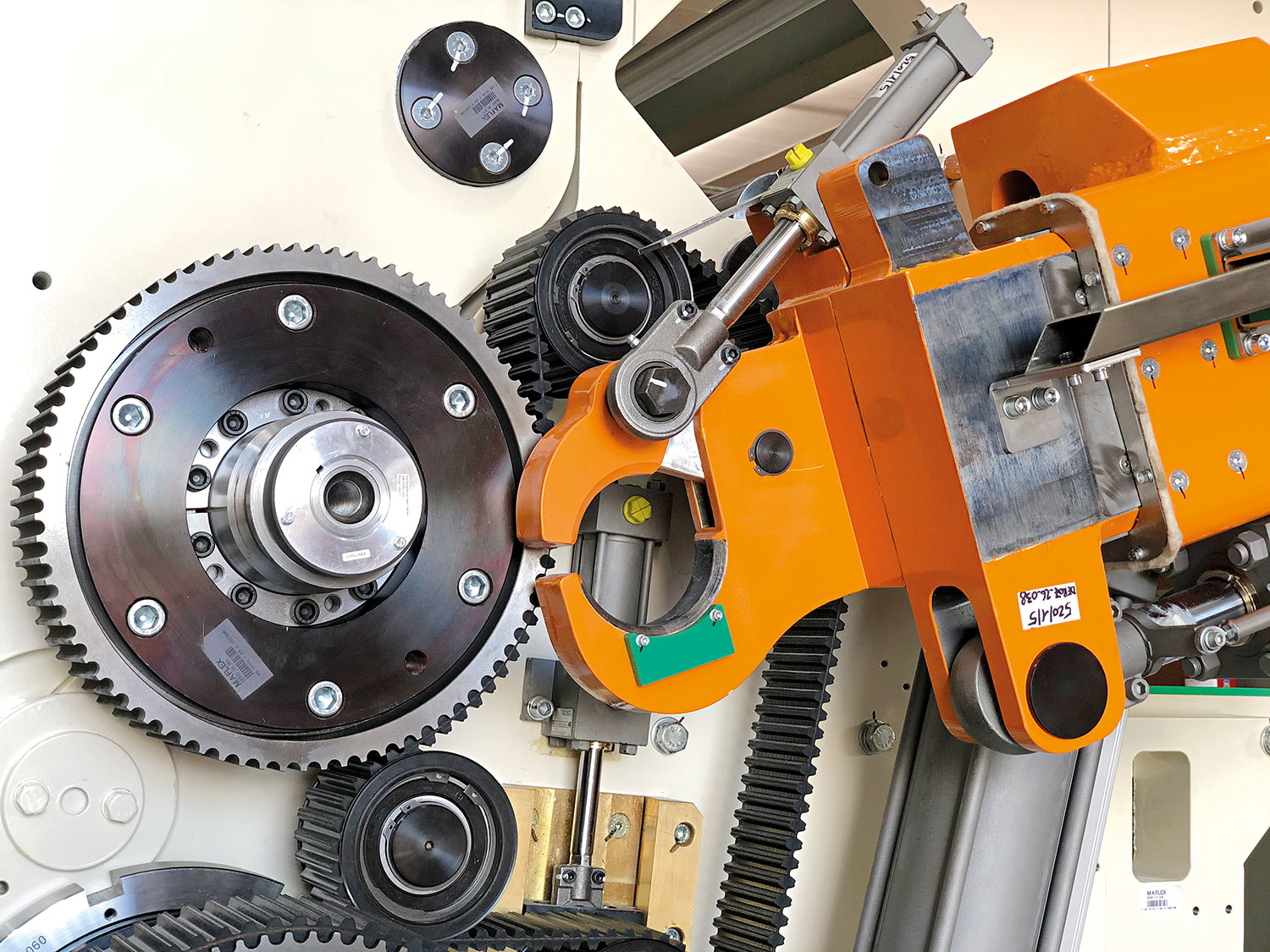

The success is driven by company values and commitments. Reliability and consistency are a couple of examples. Maflex designs and builds all equipment in house, creating a very high standard of quality control. To ensure this, all parts and components are reviewed internally when received, prior to assembly. With state-of-the-art controls and components, Maflex provides proven, easy to operate equipment that satisfies the needs of the customer. The clean and simple design of the equipment eliminates the need for “specialized” mechanics.

In order to meet the market’s demand over the past few years, Maflex has added new equipment to its portfolio of offerings.

The universal clamping section utilized on all log saw platforms has been a game changer – no more need for change parts, all changes are done through the HMI. This creates quicker changeovers, as well as a safer environment for the operators. The roll change on the HERACLE embosser/laminator can be done automatically within 3 minutes and is tool free. All of this is done without breaking the web. This, too, is done via HMI, which ensures the safety of the operator. Another example is the HERMES continuous rewinder, which is capable of running solid, cored, and coreless products. The LADON is one of the best performing industrial log saws on the market, able to handle very dense rolls of up to 330mmin diameter. The recently developed PLUS version has a specific motion control which allows for faster speeds (30% more cuts). Maflex is continuing to grow in the nonwoven industry, supplying winding equipment and turnkey packaging for canister wipes. Responding to the increased demand for these products, the company is excited to be a valuable supplier to this ever-growing sector. Customers have come to rely on Maflex to provide solutions to their specific

and unique needs. The Engineers work directly with the customer to determine the best design to deliver the best results.

Shaping technology on your goals

All of the machinery is modular; each is set up with its own electrical cabinet. This allows for extremely fast installation times, and also allows for easy upgrades and additional flexibility to existing lines. Units can be easily upgraded or transferred to other lines, or sold as standalone pieces of equipment, creating extra value throughout the life of the machine.

Maflex is currently integrating Industry 4.0 into its new equipment, as well as existing Maflex machinery. This technology allows interconnection to the customer’s management system and the machine, creating constant interaction. This increases performance, efficiency and quality in the process. In many countries, it also allows the customer to take advantage of important tax reliefs.

Additionally, the website maflex.it is being updated with an interactive portal where the customers can enter a “virtual parts and service dashboard”. It is specific to the customer’s equipment; they can see all the components in an exploded view drawing, asking for assistance in a simple and efficient way.

Maflex is always striving to provide the best value for the customer. It is a company full of energetic and dynamic individuals who have years of experience in the converting sector. With their bright minds, Maflex is poised to be at the forefront of many new technological advances.

Maflex Srl

MAFLEX, Tissue Converting Machinery.

Maflex operates since 1997 in the tissue converting machineries industry. The experience gained over the years has led us towards specializing in the manufacturing of complete tissue converting lines primarily intended for entry level to medium-sized enterprises operating in the field.

The philosophy pursued by the management of Maflex is to build modern machinery in the symbol of reliability. Particular importance is given to safety and the ease of use, and additionally to the personalization according to the customer’s requests.

How has Maflex been able to succeed during the crisis?

In the past year, the market has changed dramatically. As the away-from-home market struggled and the retail market surged, Maflex was provided with many opportunities to deliver retail lines across the world. Along with supplying machinery for retail bath tissue and kitchen towel, Maflex machinery was also used for the production of wipes and wiper material.

Maflex is in the process of adding more capacity to the headquarters in Lucca, which will nearly double the existing space of the production area, keeping up with the growing demand for equipment. The facility was recently remodeled, creating a modern and efficient workspace.

The North American sales, service, and production facility has been an integral part of the ongoing growth of Maflex and their global presence. North American customers have direct access to local service and sales support.

The facility is utilized for machine rebuilds, group sub assembly, parts distribution, and hands on/classroom training.

What does Maflex attribute to these successes?

The success is driven by company values and commitments. Reliability and consistency are a couple of examples. Maflex designs and builds all equipment in house, creating a very high standard of quality control. To ensure this, all parts and components are reviewed internally when received, prior to assembly. With state-of-the-art controls and components, Maflex provides proven, easy to operate equipment that satisfies the needs of the customer. The clean and simple design of the equipment eliminates the need for “specialized” mechanics.

In order to meet the market’s demand over the past few years, Maflex has added new equipment to its portfolio of offerings.

The universal clamping section utilized on all log saw platforms has been a game changer – no more need for change parts, all changes are done through the HMI. This creates quicker changeovers, as well as a safer environment for the operators. The roll change on the HERACLE embosser/laminator can be done automatically within 3 minutes and is tool free. All of this is done without breaking the web. This, too, is done via HMI, which ensures the safety of the operator. Another example is the HERMES continuous rewinder, which is capable of running solid, cored, and coreless products. The LADON is one of the best performing industrial log saws on the market, able to handle very dense rolls of up to 330mmin diameter. The recently developed PLUS version has a specific motion control which allows for faster speeds (30% more cuts). Maflex is continuing to grow in the nonwoven industry, supplying winding equipment and turnkey packaging for canister wipes. Responding to the increased demand for these products, the company is excited to be a valuable supplier to this ever-growing sector. Customers have come to rely on Maflex to provide solutions to their specific

and unique needs. The Engineers work directly with the customer to determine the best design to deliver the best results.

Shaping technology on your goals

All of the machinery is modular; each is set up with its own electrical cabinet. This allows for extremely fast installation times, and also allows for easy upgrades and additional flexibility to existing lines. Units can be easily upgraded or transferred to other lines, or sold as standalone pieces of equipment, creating extra value throughout the life of the machine.

Maflex is currently integrating Industry 4.0 into its new equipment, as well as existing Maflex machinery. This technology allows interconnection to the customer’s management system and the machine, creating constant interaction. This increases performance, efficiency and quality in the process. In many countries, it also allows the customer to take advantage of important tax reliefs.

Additionally, the website maflex.it is being updated with an interactive portal where the customers can enter a “virtual parts and service dashboard”. It is specific to the customer’s equipment; they can see all the components in an exploded view drawing, asking for assistance in a simple and efficient way.

Maflex is always striving to provide the best value for the customer. It is a company full of energetic and dynamic individuals who have years of experience in the converting sector. With their bright minds, Maflex is poised to be at the forefront of many new technological advances.

Products

Accumulators, Anilox rollers, Conveyor belts, Core Maker, Corewinders, Cutters for toilet paper, Embossers, Embossing machines, Embossing rollers, Kitchen roll machines, Log loaders, Log Saw, Machine knives, Paper converting machines, Paper towel machines, Printing Units, Rewinders, Tail sealer, Toilet paper roll machines, Unwinders, Unwinding and reeling machines, Winders revamping .