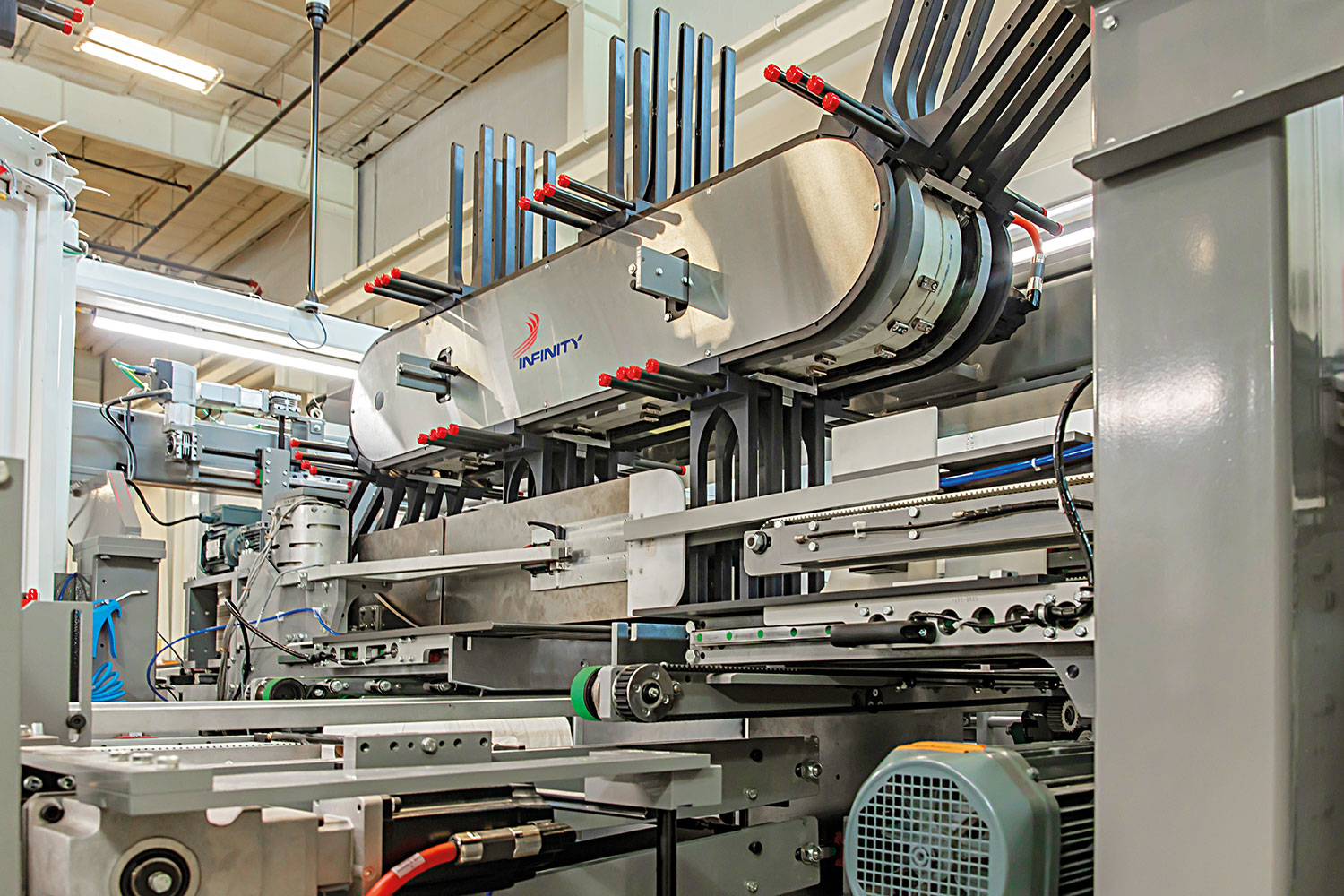

The VISION G3 multi-pack wrapper has been designed from the ground up by some of the best tissue packaging engineers on the planet, setting the global stage with a new standard in tissue packaging production. The VISION G3 is capable of producing packs of up to five lanes wide, three layers high and six rows deep. The machine offers many key features such as a small footprint, increased speeds, fast installation time, integrated frame with guarding, larger roll diameter range, sustainable design practices, cantilevered overhead and most notably a telescopic poly unwind (patent pending). However, the advantages don’t end there. At the infeed of the machine, the choke belts are top and bottom belts which allow for a narrower machine, but at the same time allow for a larger maximum infeed roll diameter (up to 250mm on two or three lanes or 190mm on all four lanes). In addition this development allows customers to easily add a 5th lane in the future without major re-work to the machine. The infeed also features an integrated single bar and stacker which produces a shorter machine. The machine body features a unique cantilevered overhead design which allows for complete access to the entire machine. The overhead is shorter than other machines on the market so this in turn generates higher speeds. The overhead trolleys are uniform so there are no pushers or retainers and there is an extra pitch for smaller formats. In addition specialized side tuckers allow for high-quality paper wrapped packages.

The poly unwind of the VISION G3 is truly different. The poly unwind features a telescoping design (patent pending) which adjusts position for smaller pack formats by telescoping closer to the elevator. This allows for the sheet to travel less distance thus generating higher speeds and better pack quality since the poly has less time to skew. This revolutionary new feature allows the VISION G3 multi-pack wrapper to operate like a dedicated single roll wrapper when producing single roll towel and bath formats. Other features of the unwind section include a shaftless unwind, self-setting helical knife and quick-change bottom anvil knife cartridge.

There are many distinct overall features that are worth noting as well, such as an easy three-piece shipping system. Since the wrapper’s frame, guarding and cabinets are integrated, Infinity can ship the machine to customers in three pieces, which allows customers to reduce the installation time of the machine to one day! This means that Infinity can have finished packs out of the machine by day two of an installation! Other overall features include a lower working height for shorter operators, no chains on the machine, no trapped belts on the machine, direct drive infeed belts (less pulleys and timing belts), closed loop 24V motors for automatic adjustments with torque feedback and the ability to add a third layer at a later time.

A global vision, focused on tissue and hygiene packaging solutions

In the age of sustainability, this machine is also showing its strength. The machine can be equipped with IE3 rated continuous duty motors for higher efficiency, an electronically controlled unwind dancer to reduce air consumption, the removal of the counter folder air cylinders to reduce air consumption and zoned lubrication with four separate zones to meter precise amounts of lubrication per application. Another area of strength is on the stacker motor; the machine will turn off the motor and engage the break when in stand-by mode in order to reduce power consumption. In addition the Vision G3 features a minimum of moving parts to reduce future maintenance costs thus reducing the carbon footprint of the machine. Other optional features include light annunciation for faults, light annunciation of sealing belt temperature, a live-streaming camera system for machine monitoring/troubleshooting, tablet connectivity, a bar code reader to confirm correct materials and the capability to add a linear motor overhead. The VISION G3 multi-pack wrapper’s list of advantages is long and are best covered in a meeting with Infinity’s sales team or by visiting visionG3.com. The machine is also available to see virtually or in person at Infinity’s open house which is taking place from October through November of 2021 in Green Bay, Wisconsin and in Italy during 2022. Put the future of packaging in your line of sight with the VISION G3 wrapper from Infinity Machine and Engineering Corp.

Infinity Machine & Engineering Corp.

For as long as our value proposition satisfies our markets and our customers, our intention is to grow without limits and to do our best to realize our maximum potential. In virtually every facet of the Infinity organization, we strive to reach perfection and provide longevity and continuity for our customers, our employees, and our community.

Our Mission

To focus on the success of our customers by providing them with innovative, value-driven, best-in-class, integrated engineering solutions.

To achieve the objectives set by our customers within the budget and time-frame promised.

To manage all aspects of the company in concert with our corporate values.

Our Philosophy

Focus on strategic partnerships with customers and suppliers.

Develop a broad range of best-in-class products and services.

Exercise the best engineering and business practices available with applied technology as a cornerstone.

Design and build machines per our customers’ specifications.

The VISION G3 multi-pack wrapper has been designed from the ground up by some of the best tissue packaging engineers on the planet, setting the global stage with a new standard in tissue packaging production. The VISION G3 is capable of producing packs of up to five lanes wide, three layers high and six rows deep. The machine offers many key features such as a small footprint, increased speeds, fast installation time, integrated frame with guarding, larger roll diameter range, sustainable design practices, cantilevered overhead and most notably a telescopic poly unwind (patent pending). However, the advantages don’t end there. At the infeed of the machine, the choke belts are top and bottom belts which allow for a narrower machine, but at the same time allow for a larger maximum infeed roll diameter (up to 250mm on two or three lanes or 190mm on all four lanes). In addition this development allows customers to easily add a 5th lane in the future without major re-work to the machine. The infeed also features an integrated single bar and stacker which produces a shorter machine. The machine body features a unique cantilevered overhead design which allows for complete access to the entire machine. The overhead is shorter than other machines on the market so this in turn generates higher speeds. The overhead trolleys are uniform so there are no pushers or retainers and there is an extra pitch for smaller formats. In addition specialized side tuckers allow for high-quality paper wrapped packages.

The poly unwind of the VISION G3 is truly different. The poly unwind features a telescoping design (patent pending) which adjusts position for smaller pack formats by telescoping closer to the elevator. This allows for the sheet to travel less distance thus generating higher speeds and better pack quality since the poly has less time to skew. This revolutionary new feature allows the VISION G3 multi-pack wrapper to operate like a dedicated single roll wrapper when producing single roll towel and bath formats. Other features of the unwind section include a shaftless unwind, self-setting helical knife and quick-change bottom anvil knife cartridge.

There are many distinct overall features that are worth noting as well, such as an easy three-piece shipping system. Since the wrapper’s frame, guarding and cabinets are integrated, Infinity can ship the machine to customers in three pieces, which allows customers to reduce the installation time of the machine to one day! This means that Infinity can have finished packs out of the machine by day two of an installation! Other overall features include a lower working height for shorter operators, no chains on the machine, no trapped belts on the machine, direct drive infeed belts (less pulleys and timing belts), closed loop 24V motors for automatic adjustments with torque feedback and the ability to add a third layer at a later time.

A global vision, focused on tissue and hygiene packaging solutions

In the age of sustainability, this machine is also showing its strength. The machine can be equipped with IE3 rated continuous duty motors for higher efficiency, an electronically controlled unwind dancer to reduce air consumption, the removal of the counter folder air cylinders to reduce air consumption and zoned lubrication with four separate zones to meter precise amounts of lubrication per application. Another area of strength is on the stacker motor; the machine will turn off the motor and engage the break when in stand-by mode in order to reduce power consumption. In addition the Vision G3 features a minimum of moving parts to reduce future maintenance costs thus reducing the carbon footprint of the machine. Other optional features include light annunciation for faults, light annunciation of sealing belt temperature, a live-streaming camera system for machine monitoring/troubleshooting, tablet connectivity, a bar code reader to confirm correct materials and the capability to add a linear motor overhead. The VISION G3 multi-pack wrapper’s list of advantages is long and are best covered in a meeting with Infinity’s sales team or by visiting visionG3.com. The machine is also available to see virtually or in person at Infinity’s open house which is taking place from October through November of 2021 in Green Bay, Wisconsin and in Italy during 2022. Put the future of packaging in your line of sight with the VISION G3 wrapper from Infinity Machine and Engineering Corp.

Products

Packaging machines for paper products.