It should come as no surprise that the Paper Industry is making a continuous effort to reduce energy and utility consumption, both for economic and environmental benefits. Nash is well known for its de-watering vacuum systems for machines ranging from pulp to tissue.

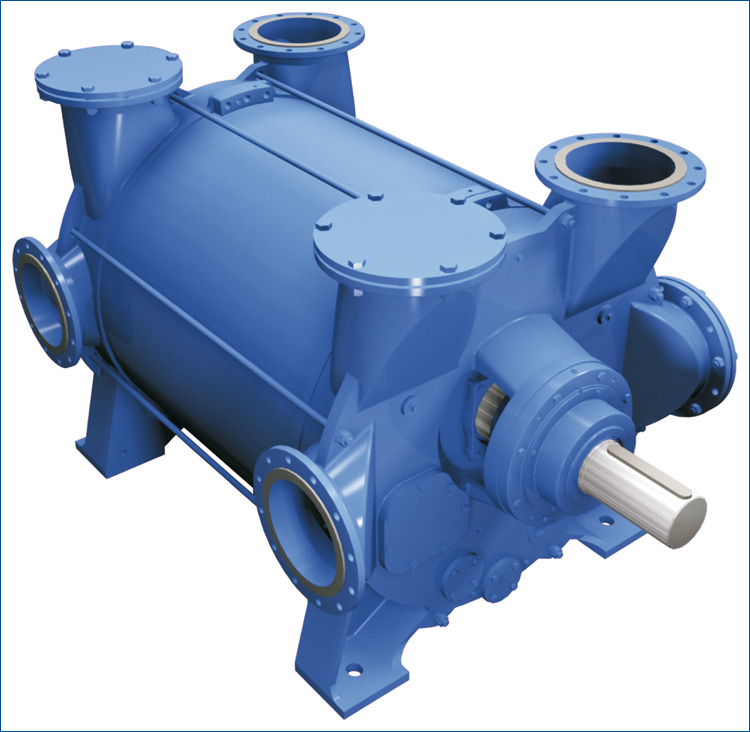

The ubiquitous NASH Liquid Ring Pump is recognized globally for reliable performance on this application. Drawbacks, however, include water usage and a perception of low efficiency. In response, Gardner Denver Nash has developed a unique hybrid vacuum system that combines NASH liquid ring pumps with Hoffman & Lamson multistage centrifugal blowers. The NASH hybrid vacuum system for paper production reduces power consumption by up to 30% while improving performance and system flexibility.

Gardner Denver Nash manufactures both the liquid ring vacuum pumps and multistage centrifugal blowers used in this hybrid vacuum system. With over 110 years of engineering expertise, our global team combines the two technologies into one customized system solution that offers maximum performance and efficiency benefits. In this system, NASH liquid ring vacuum pumps are used on high vacuum services, including the couch, pickup, and felt conditioning.

For maximum flexibility and efficiency, variable speed drives are incorporated into the system. This is especially important for machines that produce multiple paper grades. Hoffman & Lamson multistage centrifugal blowers, part of the Gardner Denver Nash Division’s product line, serve the forming section vacuum duties. The multistage centrifugal blowers can more efficiently serve low vacuum requirements, reducing power and eliminating water consumption in this section.

As an additional benefit, there is potential for heat recovery from the exhaust air of these blowers which

could result in additional energy savings. In addition to efficiency improvements, the Nash paper hybrid vacuum system improves de-watering in the press section resulting in reduced steam loads in the dryer section. Other benefits include low noise levels, low maintenance costs, and improved reliability, and a full system warranty. The NASH Hybrid Vacuum System for paper production is a step forward in optimizing valuable resources while maintaining a reliable and low maintenance paper machine vacuum system.

About Gardner Denver NASH

Founded in 1905 as Nash Engineering, Gardner Denver Nash was created in September 2004. Today, as Gardner Denver Nash, we provide improved global service and technical support for Nash liquid ring vacuum pumps, compressors and engineered systems, serving the chemical, petroleum, power, paper, mining, environmental, food, and wastewater treatment industries.

For almost 100 years Nash has supplied the paper industry with reliable vacuum pumps, compressors, and engineered systems

When it is apparent that dozens of solutions to the need for a vacuum system are potentially feasible, NASH engineers utilize their expertise to search out the best alternative. We investigate with our customers the economics of valuable product recovery. We take into account such environmental considerations as disposal of unwanted process carryover.

We find ways to conserve power, water, and heat energy. We evaluate system arrangements, scheduled maintenance and service life. We analyze available ratios of first cost to operating costs, so that our customers can tailor those different types of expenditures to their company’s financial objectives. In summary what we do is to supply ENGINEERED SYSTEMS designed to solve customer problems.

Nash – Zweigniederlassung der Gardner Denver Deutschland GmbH

For more than 100 years Nash has supplied the paper industry with reliable vacuum pumps, compressors, and engineered systems for paper production and water removal for paper machines. Our reputation in the paper industry is well known and hard earned. The reason is simple – NASH liquid ring vacuum pumps and systems are proven to help your mill produce quality paper at a lower cost. With product upgrades that improve reliability and reduce water consumption, we continue to offer innovative solutions that further enhance reliability while increasing energy savings and profitability for your mill.

It should come as no surprise that the Paper Industry is making a continuous effort to reduce energy and utility consumption, both for economic and environmental benefits. Nash is well known for its de-watering vacuum systems for machines ranging from pulp to tissue.

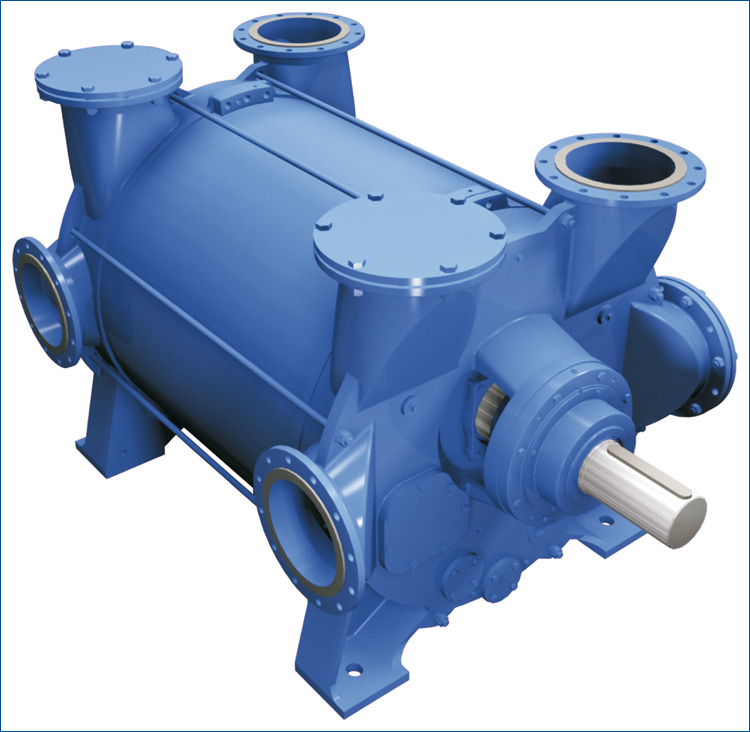

The ubiquitous NASH Liquid Ring Pump is recognized globally for reliable performance on this application. Drawbacks, however, include water usage and a perception of low efficiency. In response, Gardner Denver Nash has developed a unique hybrid vacuum system that combines NASH liquid ring pumps with Hoffman & Lamson multistage centrifugal blowers. The NASH hybrid vacuum system for paper production reduces power consumption by up to 30% while improving performance and system flexibility.

Gardner Denver Nash manufactures both the liquid ring vacuum pumps and multistage centrifugal blowers used in this hybrid vacuum system. With over 110 years of engineering expertise, our global team combines the two technologies into one customized system solution that offers maximum performance and efficiency benefits. In this system, NASH liquid ring vacuum pumps are used on high vacuum services, including the couch, pickup, and felt conditioning.

For maximum flexibility and efficiency, variable speed drives are incorporated into the system. This is especially important for machines that produce multiple paper grades. Hoffman & Lamson multistage centrifugal blowers, part of the Gardner Denver Nash Division’s product line, serve the forming section vacuum duties. The multistage centrifugal blowers can more efficiently serve low vacuum requirements, reducing power and eliminating water consumption in this section.

As an additional benefit, there is potential for heat recovery from the exhaust air of these blowers which

could result in additional energy savings. In addition to efficiency improvements, the Nash paper hybrid vacuum system improves de-watering in the press section resulting in reduced steam loads in the dryer section. Other benefits include low noise levels, low maintenance costs, and improved reliability, and a full system warranty. The NASH Hybrid Vacuum System for paper production is a step forward in optimizing valuable resources while maintaining a reliable and low maintenance paper machine vacuum system.

About Gardner Denver NASH

Founded in 1905 as Nash Engineering, Gardner Denver Nash was created in September 2004. Today, as Gardner Denver Nash, we provide improved global service and technical support for Nash liquid ring vacuum pumps, compressors and engineered systems, serving the chemical, petroleum, power, paper, mining, environmental, food, and wastewater treatment industries.

For almost 100 years Nash has supplied the paper industry with reliable vacuum pumps, compressors, and engineered systems

When it is apparent that dozens of solutions to the need for a vacuum system are potentially feasible, NASH engineers utilize their expertise to search out the best alternative. We investigate with our customers the economics of valuable product recovery. We take into account such environmental considerations as disposal of unwanted process carryover.

We find ways to conserve power, water, and heat energy. We evaluate system arrangements, scheduled maintenance and service life. We analyze available ratios of first cost to operating costs, so that our customers can tailor those different types of expenditures to their company’s financial objectives. In summary what we do is to supply ENGINEERED SYSTEMS designed to solve customer problems.

Products

Fans, Pumps, Vacuum plants.