Plusline Business Development Director.

Where did the idea for this new technology come from?

As in the case of Overlayer and Tower+, the genesis of this innovation was the specific need of a customer in North America. They were looking for a high-speed packaging machine that would reduce changeover times and minimize compression – and therefore defects – on tissue boxes caused by conventional technologies using brushless motors.

Higher efficiency, optimum functionality and operational simplicity

What was the outcome?

A super-flexible solution in terms of capacity and the size of boxes handled. But that’s not all. With up to six feeding lanes and three stacking layers, Pluspack FBO has a production speed of up to 160 packs per minute, which is at least 25% faster than standard machines and with significantly reduced format changeover times.

Plusplack FBO is therefore a kind of upgrade of your Pluspack technology that has been on the market for a few years?

Yes, that’s right, an evolution of the traditional Pluspack and as such it applies to tissue boxes a technology which is already tested and verified in the packaging of toilet and kitchen towel rolls, with the advantages this confers in terms of speed and flexibility.

Plusline is expanding its horizons and has gone beyond paper and polyethylene wrapping technologies?

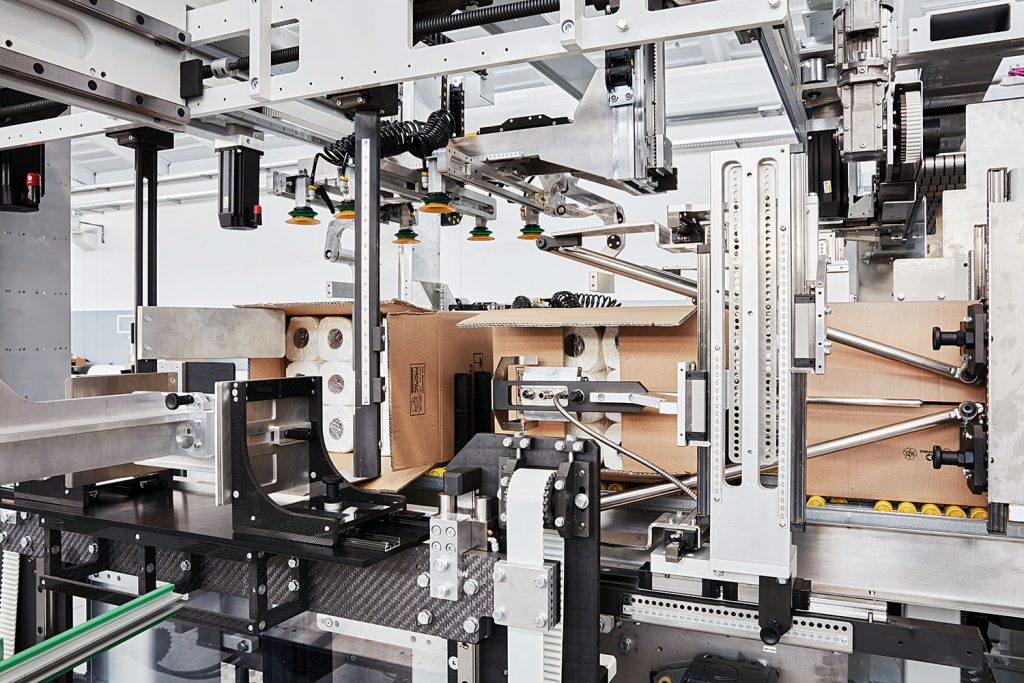

Yes, with the new Case+ case packer we have started a new chapter. It is a fully automated solution, developed to guarantee a maximum speed of up to 35 cartons per minute, compared to the industry standard which averages around 15 cartons per minute and never more than 20-25. Case+ is not only about speed, but also offers unprecedented levels of flexibility and efficiency in format changeovers. Case+ can also be configured to guarantee, according to the specific needs of the customer, different levels of performance. For this reason we offer the market three different models: Case+ 15, 22 and 40.

You are also well known for optimizing layouts. Have you managed to surpass yourself in this respect too?

Yes, we have once again challenged tradition in terms of design with this new technology. This solution is stable, robust and based on well-tested and super-compact components: it’s just 9.7 m long by 3.9 m wide.

Advanced technological solutions for the primary and secondary packaging of tissue products

Is this case packer only applicable for toilet roll and kitchen towel?

Absolutely not. This technology is suitable for boxing rolls but also folded products, industrial rolls and can have applications throughout the hygiene sector, meaning mattress pads and diapers for example. And it can handle individually packaged products or layered packs. It has all the features of our Overpack but for packaging with cartons and rather than bags.

So all the benefits guaranteed by your other technologies apply?

At PLUSLINE we adhere to a principle which defines a large part of what we do: “reduce the line, increase efficiency”. Each of our technologies must respect these principles and this development

is no exception.

Optimization and performance then, anything else to add?

All our innovations aim to simplify the user experience, reduce downtime and capex, gain efficiency and improve the quality of the finished product.

What does the future hold for Plusline?

We never stand still. We are always looking for new solutions that challenge the status quo and give concrete benefits to our customers in terms of efficiency, optimization and safety.

Can you give us some detail?

I don’t want to reveal too much, but in October, at MIAC, we presented our Overlayer & Tower+ system and talked, together with Futura, about a totally integrated process from the jumbo reel to the pallet. In Lucca, we have now installed a bundling machine at the end of the line that can also prepare the layer (i.e. the Overlayer: overpack+layer former) and a palletizer (Tower+). But what if, instead of the bagging machine, there was a case packer capable of creating the layer as well?

That would be a Case+, that can also handle layers and a palletizer.

Exactly. We are working on an upgrade of this technology that optimizes and shortens the end-of-line so it can handle cartons as well.

Case+.

Plusline S.r.l.

It has its headquarters in Bologna’s packaging valley, and a team of highly experienced technicians and professionals behind it, whose

in-depth knowledge of the product andthe production process guarantees reliability and results.

In addition to its in-house expertise, Plusline has also formed a strategic partnership with Futura to develop joint projects and perform cutting-edge technology trials.

Plusline introduces a new era in packaging. You are about to enter an age in which technology will dramatically simplify the user experience, redefine product protection and deliver improved, sustainable productivity.

In short, an era in which you will have everything you’ve been looking for.

Products

Bundlers, Machines for tissue packaging, Wrappers.