The result is GREEN EASY CRESCENT, a brand new Tissue Plant harmonising these features to meet the needs of those market segments that have a daily productive need of about 80 tons tissue paper on single machine width (Figure 1). This TM is primarily designed for all the medium-sized companies aiming at optimising every aspect of the impact of the investment.

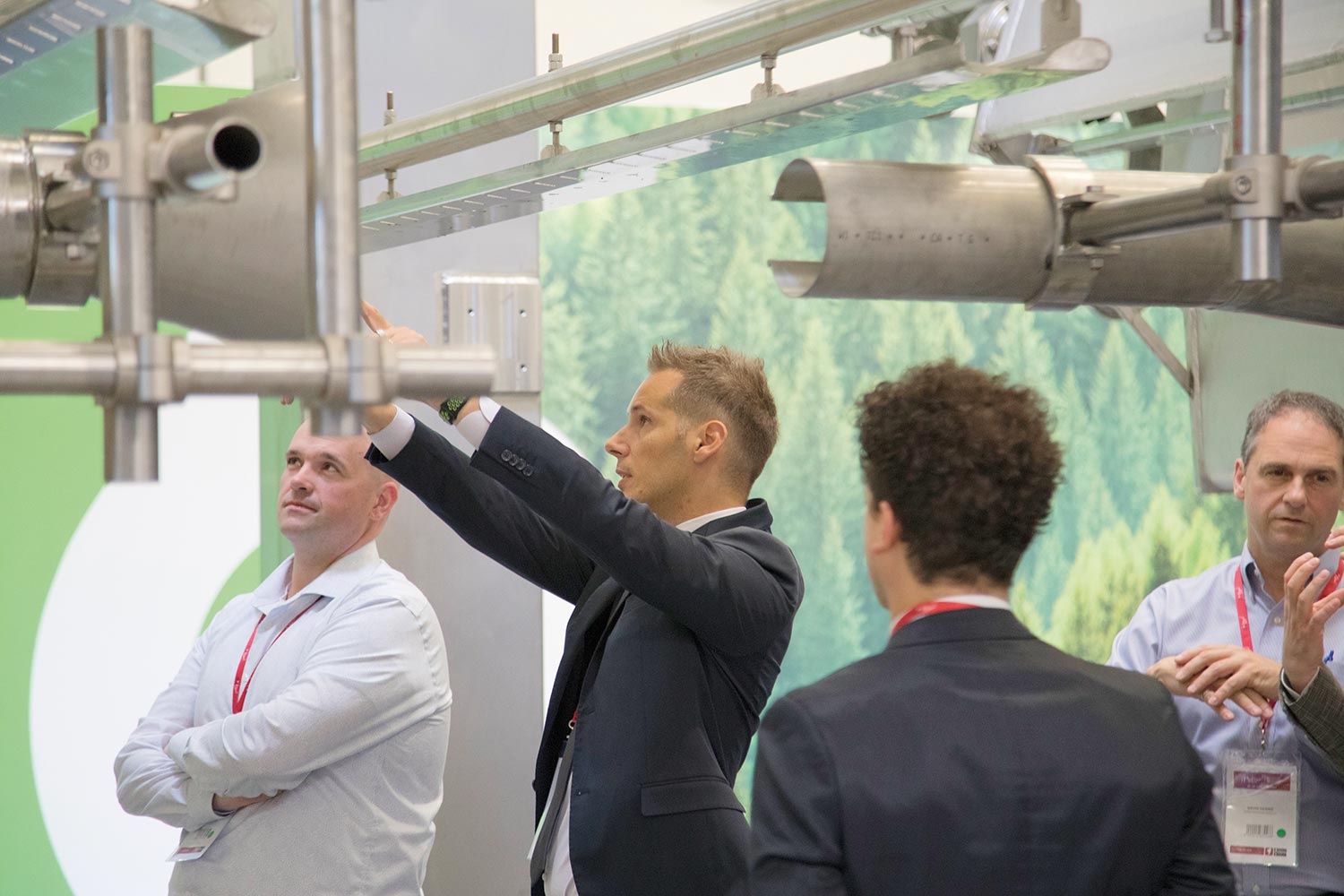

After checking its effectiveness using several complex tests performed in partnership with EIL Srl, Recard officially launched their newborn in the occasion of It’s Tissue 2018, an event that takes place in the Tuscan city every three years, where tissue manufacturers meet the most relevant technology producers of the world. That’s the place where the latest and best technological innovations for production and converting of tissue are presented. So what are the most interesting features of this new solution? Indeed, Green Easy Crescent by Recard represents now an ideal solution to reduce times and costs of building works (Figure 2), as well as emissions into the air, drastically minimizing their impact on the environment and cutting costs derived from energy consumption, which represents an expensive budget item for paper mills in many countries.

All of the machines Recard produces are manufactured in Italy to the highest standards of quality

It’s “Easy” because it is entirely built on floor level, with no need for the approach flow system pit – this way reducing design and construction costs (Figure 3), but also the time needed for construction – works in the paper mill. In addition to all this, the plant’s need for space is also reduced: just 1,800 m2 for the covered part and a maximum height of the shed of 7.3 metres.

It is “Easy” in terms of manageability. Once fully operational, thanks to its total automation and handling via DCS, the machine can be run by only 3 operators – considerably less than a traditional plant. “Easy” because its flexibility facilitates the changeover, thanks to the plant’s high automation and very short cycles of water and pulp. Certainly, the “Green” features are the most interesting and innovative aspects of this technology: as tests performed by Recard confirm, the plant’s next gen gas turbine can produce much of the energy needed, while residual exhaust gases provide all the thermal energy required for the drying of paper (Figure 4). This means 65% savings in electricity consumption, with an increase of just 15% in gas consumption compared to a traditional machine, since the system makes the most of the available energy minimizing the losses. Though it may vary depending on the country and energy suppliers, the economic advantage is therefore evident in terms of electric energy. Moreover, countries where electricity is unstable and subject to changes can benefit from a turbine that works with many different kinds of fuel, guaranteeing continuity in the production as well as a better efficiency of the system (Figure 5).

Figure 3

Figure 4

Figure 5

Recard specializes in the custom design and manufacturing of equipment and machines for the tissue paper industry

Last, but certainly not least, is the important “environmental” revolution developed by Recard for Green Easy Crescent: tests show that the innovative technological solutions implemented throughout the whole process enable 70% reduction in Nox and 60% in CO emissions in the atmosphere. Starting from a traditional Crescent Former, Recard developed an innovative technology enabling the minimization of energy related costs and the reduction of emissions in the atmosphere in a simple, low-cost way, providing a concrete answer to current fundamental needs of tissue manufacturers.

Recard S.p.A

Recard, an Italian company of the Tissue Valley of Lucca, is specialized in the customized design and production of machines and plants for tissue paper, manufactured using exclusively high-quality Italian or European products. Founded in 1962 by brothers Piero and Luciano Cardinotti together with Silvano Renieri, has attained industrial dimensions all the while maintaining its philosophy of a “craft laboratory”, a working philosophy that guarantees top production efficiency and allows placing the customer at the center of attention, creating a collaboration that goes well beyond the sale of a machine. Artisan craftsmanship, quality, competence, efficiency, reliability, flexible state-of-the-art technology, simplified organization and direct customer relationships allow supplying customized answers for the needs of companies of any size.

The result is GREEN EASY CRESCENT, a brand new Tissue Plant harmonising these features to meet the needs of those market segments that have a daily productive need of about 80 tons tissue paper on single machine width (Figure 1). This TM is primarily designed for all the medium-sized companies aiming at optimising every aspect of the impact of the investment.

After checking its effectiveness using several complex tests performed in partnership with EIL Srl, Recard officially launched their newborn in the occasion of It’s Tissue 2018, an event that takes place in the Tuscan city every three years, where tissue manufacturers meet the most relevant technology producers of the world. That’s the place where the latest and best technological innovations for production and converting of tissue are presented. So what are the most interesting features of this new solution? Indeed, Green Easy Crescent by Recard represents now an ideal solution to reduce times and costs of building works (Figure 2), as well as emissions into the air, drastically minimizing their impact on the environment and cutting costs derived from energy consumption, which represents an expensive budget item for paper mills in many countries.

All of the machines Recard produces are manufactured in Italy to the highest standards of quality

It’s “Easy” because it is entirely built on floor level, with no need for the approach flow system pit – this way reducing design and construction costs (Figure 3), but also the time needed for construction – works in the paper mill. In addition to all this, the plant’s need for space is also reduced: just 1,800 m2 for the covered part and a maximum height of the shed of 7.3 metres.

It is “Easy” in terms of manageability. Once fully operational, thanks to its total automation and handling via DCS, the machine can be run by only 3 operators – considerably less than a traditional plant. “Easy” because its flexibility facilitates the changeover, thanks to the plant’s high automation and very short cycles of water and pulp. Certainly, the “Green” features are the most interesting and innovative aspects of this technology: as tests performed by Recard confirm, the plant’s next gen gas turbine can produce much of the energy needed, while residual exhaust gases provide all the thermal energy required for the drying of paper (Figure 4). This means 65% savings in electricity consumption, with an increase of just 15% in gas consumption compared to a traditional machine, since the system makes the most of the available energy minimizing the losses. Though it may vary depending on the country and energy suppliers, the economic advantage is therefore evident in terms of electric energy. Moreover, countries where electricity is unstable and subject to changes can benefit from a turbine that works with many different kinds of fuel, guaranteeing continuity in the production as well as a better efficiency of the system (Figure 5).

Figure 3

Figure 4

Figure 5

Recard specializes in the custom design and manufacturing of equipment and machines for the tissue paper industry

Last, but certainly not least, is the important “environmental” revolution developed by Recard for Green Easy Crescent: tests show that the innovative technological solutions implemented throughout the whole process enable 70% reduction in Nox and 60% in CO emissions in the atmosphere. Starting from a traditional Crescent Former, Recard developed an innovative technology enabling the minimization of energy related costs and the reduction of emissions in the atmosphere in a simple, low-cost way, providing a concrete answer to current fundamental needs of tissue manufacturers.

Products

Headboxes, Paper machines, Paper Mills plants, Production lines, Reelers, Stock preparation systems.