For those who do not know when the first tissue rolls’ secondary wrapper was produced, using a flat PE reel, we can state that this happened in 1977 and its inventor was Mr. Paolo Cassoli. Since then, this innovative and successful concept (the tree) has revolutionized the secondary packaging market and is the only solution that is still proposed by every manufacturer of packaging machines born during the last 40 years (the leaves). As technology and electronics provided the opportunity to use more sophisticated devices, these were naturally implemented, although the breakthrough concept of 1977 was essentially unchanged and technology has only highlighted its limits. Users and the market have always requested, but partially obtained, the ability to implement:

- a very tight pack;

- outstanding packaging quality;

- registered printed film;

- relevant saving of packaging material;

- maximum stability on pallets.

Many options have been proposed, but no one has really fulfilled the market needs; in fact, only the one who has invented a solution can fully know its genesis and evolution, and consequently can change it, while improving the whole process. Continuing with the metaphor, the tree is not able to provide enough shade anymore, but also begins to bend due to its aging: there is a strong need to plant a new one. Through CPS Company (Cassoli Packaging Solutions), the entrepreneurial capability of the Cassoli family continues today with wide investments in R&D of automatic machines that can offer innovative and environmentally friendly packaging solutions at a low production cost and with a very high quality of finished product. The secondary packaging revolution has finally come. It is called “Pull Technology” and this milestone allows our customers to implement these features:

- Greater production speed;

- Save from 20% up to 40% packing material for each single package;

- “Built-in System” to use printed film;

- Customizable bag tightness;

- No need to use any shrinking tunnel;

- Footprint of less than 12 square meters.

Cassoli, with CPS Company, has written a new chapter that will revolutionize the industry with a whole new range of Secondary Pull Wrapper. This big leap forward will mark the packaging industry of tissue products forever. It is important to mention that Cassoli Packaging Solutions does not only offer innovation by means of its secondary pull wrapping technology.

Our mission is to build cutting-edge automatic systems for disposable paper and tissue products

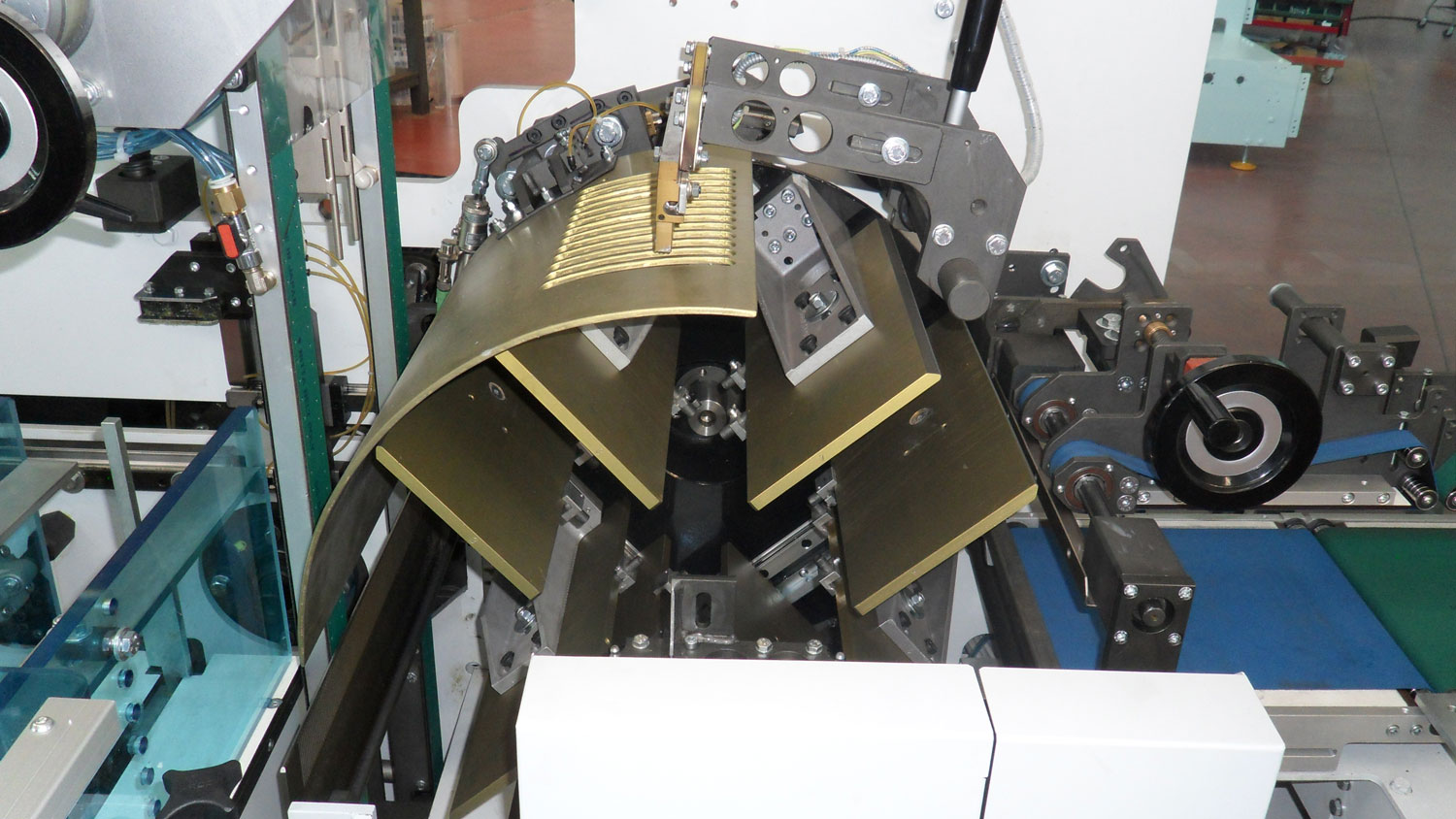

Actually, CPS Company has successfully delivered a primary wrapping machine for folded products capable of producing high-quality packs of napkins with a height of 10-12 mm. with a production speed of 120 ppm. For the packaging of folded/interfolded product CPS Company can offer the largest range of wrapping machines able to satisfy all the market needs with seven models of CPS800 series with the innovative and well proved rotative technology. Last, but not least CPS Company can provide high speed range of case packers and end-of line palletisers, as the perfect conclusion of the packing cycle.

CPS Company Srl

For over 50 years the Cassoli name has been a byword for innovation and reliability in manufacturing packaging machines for tissue and paper products, such as rolls, napkins, towels, and also personal care products.

The experience and know-how of Paolo and Stefano Cassoli are now available in CPS, a company based in Bologna which develops cutting edge automatic systems for primary, secondary and end-of-the-line packaging.

For those who do not know when the first tissue rolls’ secondary wrapper was produced, using a flat PE reel, we can state that this happened in 1977 and its inventor was Mr. Paolo Cassoli. Since then, this innovative and successful concept (the tree) has revolutionized the secondary packaging market and is the only solution that is still proposed by every manufacturer of packaging machines born during the last 40 years (the leaves). As technology and electronics provided the opportunity to use more sophisticated devices, these were naturally implemented, although the breakthrough concept of 1977 was essentially unchanged and technology has only highlighted its limits. Users and the market have always requested, but partially obtained, the ability to implement:

- a very tight pack;

- outstanding packaging quality;

- registered printed film;

- relevant saving of packaging material;

- maximum stability on pallets.

Many options have been proposed, but no one has really fulfilled the market needs; in fact, only the one who has invented a solution can fully know its genesis and evolution, and consequently can change it, while improving the whole process. Continuing with the metaphor, the tree is not able to provide enough shade anymore, but also begins to bend due to its aging: there is a strong need to plant a new one. Through CPS Company (Cassoli Packaging Solutions), the entrepreneurial capability of the Cassoli family continues today with wide investments in R&D of automatic machines that can offer innovative and environmentally friendly packaging solutions at a low production cost and with a very high quality of finished product. The secondary packaging revolution has finally come. It is called “Pull Technology” and this milestone allows our customers to implement these features:

- Greater production speed;

- Save from 20% up to 40% packing material for each single package;

- “Built-in System” to use printed film;

- Customizable bag tightness;

- No need to use any shrinking tunnel;

- Footprint of less than 12 square meters.

Cassoli, with CPS Company, has written a new chapter that will revolutionize the industry with a whole new range of Secondary Pull Wrapper. This big leap forward will mark the packaging industry of tissue products forever. It is important to mention that Cassoli Packaging Solutions does not only offer innovation by means of its secondary pull wrapping technology.

Our mission is to build cutting-edge automatic systems for disposable paper and tissue products

Actually, CPS Company has successfully delivered a primary wrapping machine for folded products capable of producing high-quality packs of napkins with a height of 10-12 mm. with a production speed of 120 ppm. For the packaging of folded/interfolded product CPS Company can offer the largest range of wrapping machines able to satisfy all the market needs with seven models of CPS800 series with the innovative and well proved rotative technology. Last, but not least CPS Company can provide high speed range of case packers and end-of line palletisers, as the perfect conclusion of the packing cycle.

Products

Bundlers, Case Packer, Distributors (Diverters), Packaging machines for paper products, Packaging systems and machines, Wrappers, Wrapping machines.