iDEAL® EvoLock® Yankee Dryer

Our new EvoLock® solution, starting from the excellent technological base of our Yankee Dryer Forged® YD, includes all the A.Celli technologies already known and appreciated, like the use of a monobloc shell forged from a single steel ingot. The novelty lies in a unique and highly innovative head-to-shell connection system, which does not require the use of structural welds or bolts. This solution allows, from an engineering point of view, to minimize the deformation of the shell edges induced by the deformation of the heads, which in itself is caused by the internal steam pressure. This important feature improves the runnability on sheet edges and consequently the efficiency of the machine.

The special design also allows to reduce the overall width of the shell, giving you the capability of drying a larger format sheet with the same existing machine gauge and, as we will analyze in the next paragraphs, to reduce the necessary inspection interventions.

Required inspections: comparison between EvoLock® and other steel Yankee Dryers

For our analysis, we will consider two types of steel Yankee Dryer on the market:

- A traditional Yankee Dryer with welded shell and shell connected to the heads by means of full penetration structural welds.

- The new A.Celli iDEAL® EvoLock® solution, with forged shell and a new head-to-shell connection system who does not require bolts nor welds.

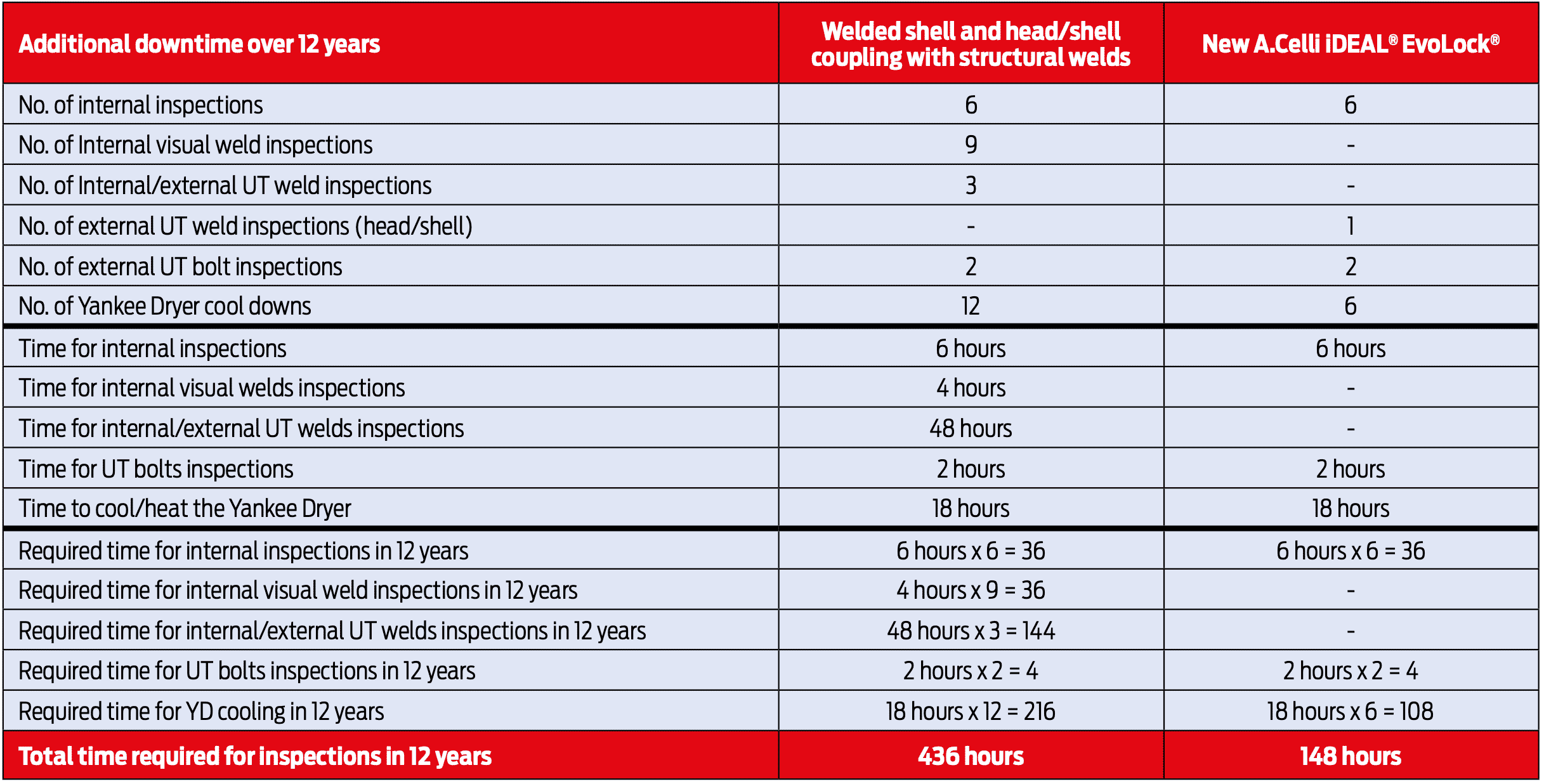

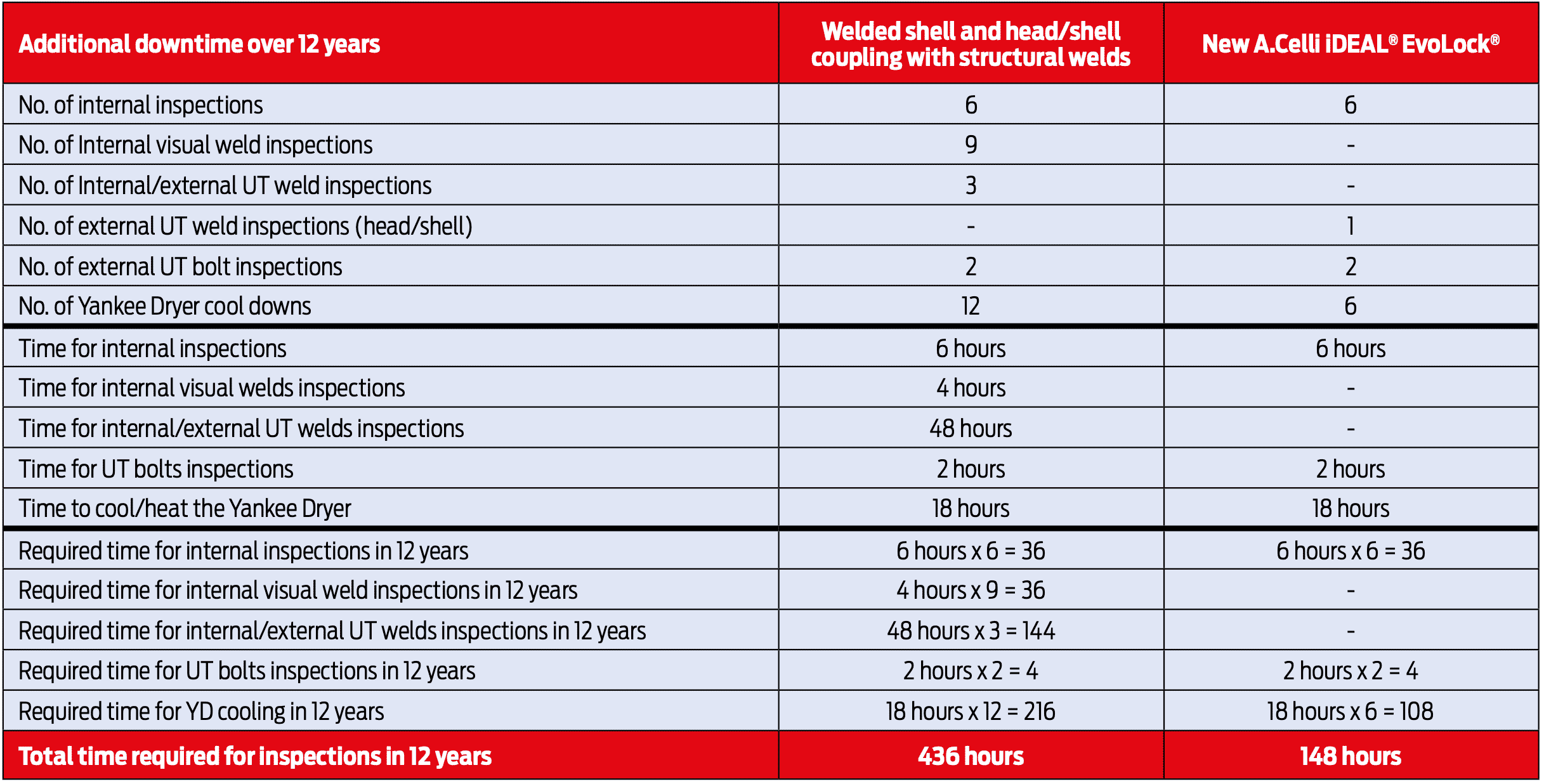

The following table compares the types of the required checks for the aforementioned Yankee Dryers during the first 12 years of life.

The evolution of the Yankee Dryer: less inspections, more productivity

From the table we can see how, for typical welded Yankees, the combination of periodic weld inspections and regular internal inspections recommended every 2 years leads to a tight schedule of invasive, expensive and prolonged checks compared to those required for the A.Celli iDEAL® EvoLock® Yankee Dryers. The greatest impact of these interventions is due to the need to completely cool the cylinders for the inspection of the internal welds. As for the Yankee Dryers of the iDEAL® product family, the staff will have to access them only for the biennial visual inspections typical of all Yankees, while the ultrasound tests are prescribed only for the structural screws which are all located on the outside, and therefore do not require the complete cooling of the cylinder. In the table, we will associate the different types of inspection and their respective intervals with the typical times necessary for their execution to calculate the total downtime of the Yankee cylinders during the first 12 years of life.

In conclusion, the results clearly show the advantage of A.Celli’s new EvoLock® Yankee Dryer which, compared to conventional solutions, is unmatched in terms of time and costs saved on periodic inspections.

A.Celli Paper S.p.A.

A.Celli Paper S.p.A., is specialized in technologically advanced system solutions for complete turnkey plants from stock preparation to roll handling and packaging. A.Celli’s proven expertise in the manufacture and rebuilding of Tissue Paper Machines with a daily production capacity from 30 to 260 tonnes, and of rewinders for tissue and flat papers and cardboard. The innovative MySp@res® system and the 24/7 post-sales assistance service complete A.Celli’s offer.

iDEAL® EvoLock® Yankee Dryer

Our new EvoLock® solution, starting from the excellent technological base of our Yankee Dryer Forged® YD, includes all the A.Celli technologies already known and appreciated, like the use of a monobloc shell forged from a single steel ingot. The novelty lies in a unique and highly innovative head-to-shell connection system, which does not require the use of structural welds or bolts. This solution allows, from an engineering point of view, to minimize the deformation of the shell edges induced by the deformation of the heads, which in itself is caused by the internal steam pressure. This important feature improves the runnability on sheet edges and consequently the efficiency of the machine.

The special design also allows to reduce the overall width of the shell, giving you the capability of drying a larger format sheet with the same existing machine gauge and, as we will analyze in the next paragraphs, to reduce the necessary inspection interventions.

Required inspections: comparison between EvoLock® and other steel Yankee Dryers

For our analysis, we will consider two types of steel Yankee Dryer on the market:

- A traditional Yankee Dryer with welded shell and shell connected to the heads by means of full penetration structural welds.

- The new A.Celli iDEAL® EvoLock® solution, with forged shell and a new head-to-shell connection system who does not require bolts nor welds.

The following table compares the types of the required checks for the aforementioned Yankee Dryers during the first 12 years of life.

The evolution of the Yankee Dryer: less inspections, more productivity

From the table we can see how, for typical welded Yankees, the combination of periodic weld inspections and regular internal inspections recommended every 2 years leads to a tight schedule of invasive, expensive and prolonged checks compared to those required for the A.Celli iDEAL® EvoLock® Yankee Dryers. The greatest impact of these interventions is due to the need to completely cool the cylinders for the inspection of the internal welds. As for the Yankee Dryers of the iDEAL® product family, the staff will have to access them only for the biennial visual inspections typical of all Yankees, while the ultrasound tests are prescribed only for the structural screws which are all located on the outside, and therefore do not require the complete cooling of the cylinder. In the table, we will associate the different types of inspection and their respective intervals with the typical times necessary for their execution to calculate the total downtime of the Yankee cylinders during the first 12 years of life.

In conclusion, the results clearly show the advantage of A.Celli’s new EvoLock® Yankee Dryer which, compared to conventional solutions, is unmatched in terms of time and costs saved on periodic inspections.

Products

AC motors, AC-DC drives, Agitator tanks, Air compressors, Air conditioning plants, Assembling, Blade holders, Bleaching plants, Calender cylinders, Calender drives, Calenders, Calenders revamping, Chemical fluid pumps, Chest mixers, Chests, Chromium plating, Circuit water cleaning, Cleaners, Cleaning systems, Cogeneration systems + paper drying applications, Consultancy services, Control and switch panels, Controlled wind reelers, Conveying screws, Conveying systems for paper reels, Conveyors, Core drums, Couplings all kinds, Creping blades, Creping cylinders, Cutter drives, Cylinders, DC motors, Deflakers, Deinking systems, Disc filters, Dispersing machines, Doctor holding devices, Doctor motors, Doctors and doctor blades, Dosing pumps, Dryers and drying plants, Drying cylinders, Drying hoods, Dust extractors, Effluent tratment plants, Electrical drives, Electrical equipments, Electrical motors, Energy Saving, Expansion Joints, Fabric guide, Fabric stretcher, Felt conditioning equipments, Felt guide, Felt stretcher, Felts, Flotation save-alls, Flotations plants, Flow meter, Foils, Forming fabrics, Gaskets, Gears, Grinding service for drying and creping cylinders, Headboxes, Heat exchangers, Heat recovery systems, High density cleaners, High pressure pumps, Industrial gaskets, Lubrication plants and oils, Machine knives and tools, Maintenance, Mandrels, Mechanical screw jacks, Mechanical seals, Medium consistence pumps, Mixers, Nickel plating, Non-woven machines, Nozzles, Packaging systems and machines, Palletiser - Palletising, Palletising lines, Paper machine drives, Paper machines, Paper machines revamping, Paper Mills plants, Perforated screen plates, Pipelines, Presses, Pressure rolls, Pressurized headboxes, Pulpers, Pulpers for paper machines, Pumps, Recovery plants, Reelers, Refiner disks, Refiners, Rewinders, RFID, Roll covers, Roller bearings for paper machines, Rolls, Rope guides, Rubber rolls, Safety flange shields, Screens, Screw presses, Seals, Seals for pumps and valves, Shafts, Shear cut systems, Shower pipes, Slitter knives, Slitter-winders, Slitter-winders revamping, Sludge dewatering plants, Sludge pumps, Spare parts, Spreader cylinders, Standard chemical pumps, Steam and condensate systems, Stock preparation systems, Suction box bars, Suction press rolls, Suction roll covers, Suction rolls, Tail Breaker, Tail Cutters, Technical service, Training Courses, Twin wire formers, Vacuum plants, Vapour hoods, Ventilation equipments, Waste disposal plants, Waste paper preparation systems, Waste water plants, Water preparation plants, Winder drives, Winders, Winding shafts, Yankee cylinders, Yankee hoods .