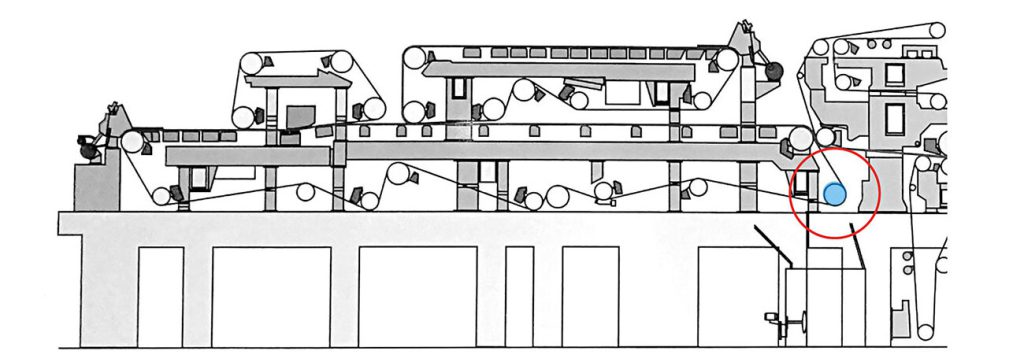

Issues with the transfer of drive energy on wire drive rolls continue to present challenges in production practice that lead to the unnecessary wastage of resources. Such machine-related issues are often detected too late or not at all. The consequences can be significant: unnecessarily high wear on the roll cover, increased wear on the running side of the wire and even short-term machine failures. Can sensors help detect drive issues with the wire drive roll? This was the question that SchäferRolls, a globally recognised roll cover manufacturer with a comprehensive range of roll-related consulting and services, put to itself and service partner Countroll®.

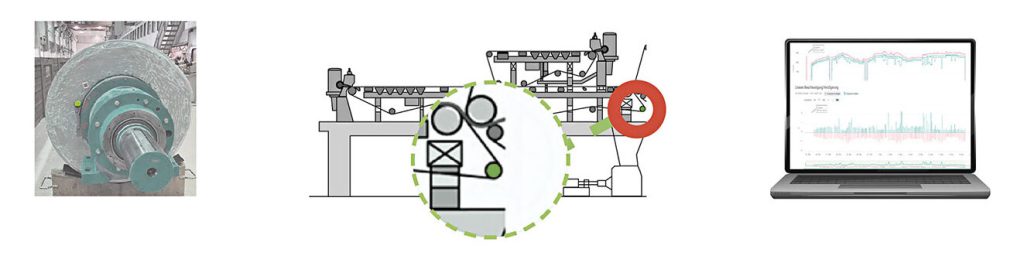

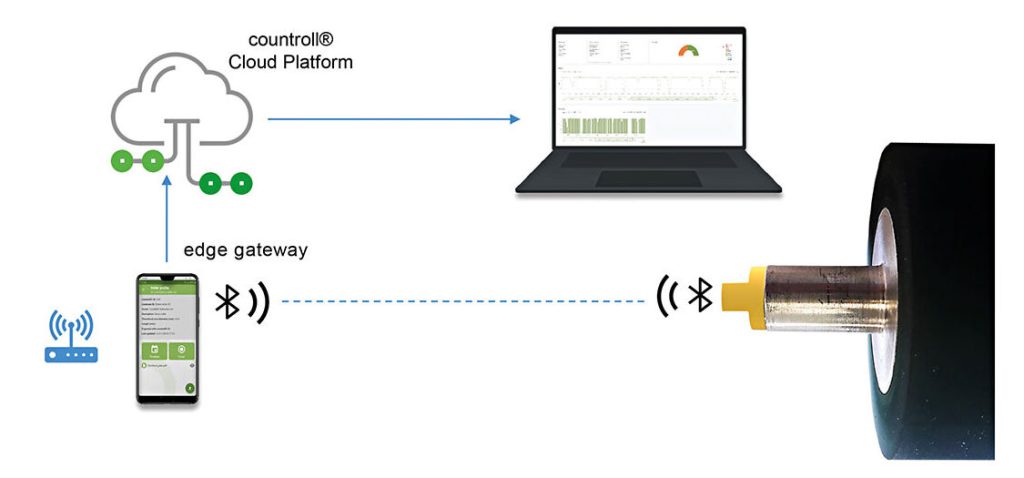

The company Countroll®, a specialist in the development of digital roll management software, first presented a sensor that it had developed to help analyse some of these issues. SchäferRolls and Countroll® then worked together to create a new product, Sensor Data Service. These sensors are used to directly analyse and monitor weak points at roll positions on the machine. They are also used to monitor rotation, speed, acceleration/deceleration, ambient temperatures, operating/idle times and can also measure time-dependent vibrations – vibrations that are recorded in a defined time window to allow for an analysis of a change in the machine condition.

Tradition, development and innovation

The sensor was tested at a SCHÄFERROLLS customer from the paper industry to check the promised added value. In this case, the wear on the roll cover was most likely caused by slippage; the change in speed between the wire and the roll cover. The material properties of the roll cover, in conjunction with the wire and the system settings, were unable to transfer sufficient drive energy to the wire. However, thanks to the sensor, the drive process could be monitored continuously directly on the roll. In the first step, a sensor was installed on the existing roll. From October 2022 to February 2023, the SchäferRolls experts collected and analysed the relevant data and discussed it with their customer. The roll cover was then replaced with the SchäferRolls Q.drive roll cover, which is optimised for this position. The SchäferRolls application specialists also installed a measurement sensor on this roll and, in March 2023, the customer installed the roll in the machine. During the following months, the measured data was evaluated and analysed on site at the customer and at SchäferRolls. In a further step, the data measurements and analyses from the Q.drive SchäferRolls roll cover were compared with those of a competitor cover. This identified a reduction in acceleration and deceleration activities during a linear measurement. The comparison measurement also allowed the experts to reduce the acceleration and deceleration values by 50 when using Q.drive. Further investigations and data analyses are currently underway to confirm this diagnosis.

The success of the sensors has already been confirmed: in July 2024, the roll that was installed in the customer’s machine in March 2023 is still running smoothly. Running time has increased from 6 to 15 months and there is initial evidence of optimised transfer of drive energy compared to previous roll cover applications. The effects on wire wear and accompanying resource savings, such as maintenance and energy costs, are currently being evaluated and collated. The engineers also expect these findings to be positive. The SchäferRolls team of experts has since received further customer enquiries, which it is carefully evaluating.

Our quality solutions are your quality solutions.

With every turn of the roll.

The partnership between SchäferRolls and Countroll® dates back to the beginning of 2022. The SchäferRolls Management Service – SRMS, is a further component of SchäferRolls’ service offering. SchäferRolls draws on its many years of experience when evaluating data, helping its customers swiftly identify, understand and resolve issues with their machines.

This partnership will also enable the joint optimisation of the product in real-world applications through the combination of comprehensive roll cover application knowledge and digitalisation solution expertise.

SchäferRolls GmbH

SchäferRolls has been producing polymer-based roll covers since 1946.

The firm is a leading name in the industry, at home and abroad – renowned for its precision, technical expertise and solid track record. SchäferRolls offers a wide range of products and full range of services. Our production machines can be adapted to the handling and processing characteristics of rolls of all sizes – and our products are sold through a seamless sales network in every corner of the globe.

Products

Calender cylinders, Consultancy services, Embossing rollers, Maintenance, Pressure rolls, Roll covers, Rolls, Rubber rolls, Suction press rolls, Suction roll covers, Suction rolls, Technical service .