Yankee hoods installed in the past are very often equipped with burners designed to guarantee drying capacity and high reliability, but with no specific target about efficiency and emissions.

In the last few years, energy and environmental issues became important and drove great design changes. Now it is more correct to speak about “combustion systems” and not simply “burners”. A combustion system is made by: the burner itself; combustion chamber; control system (in particular the control of combustion air flow following variable .0).

The design of the whole combustion system must guarantee the compliance with highly restrictive rules nowadays in force in Europe, North America, Australia. Furthermore, in addition to Country regulation, there are local rules that sometimes require special characteristics, mostly in terms of pollution emissions.

Novimpianti is a primary supplier for the paper industry worldwide

Novimpianti is frequently asked to update existing combustion systems, in order to improve thermal efficiency and respect all restrictions to the exhaust. In this case the first step must be an investigation, to understand the current equipment, fix all targets and help mill management to choose the best strategy. Of course there are many parameters to be considered, like:

» Existing burners and combustion chambers characteristics;

» Maximum necessary power (avoiding useless oversizing);

» Available combustion air temperature (some burners can accept more than 300°C);

» Impact in air system layout;

» CO and NOx limits (e.g. 50mgCO /Nm3 @17%O2);

» Burner turndown (usually from 10:1 to 20:1);

» Combustion air-to-gas ratio control;

» In-line or corner burner;

» Process air injection into corner burner combustion chamber.

Combustion chamber – latest developments

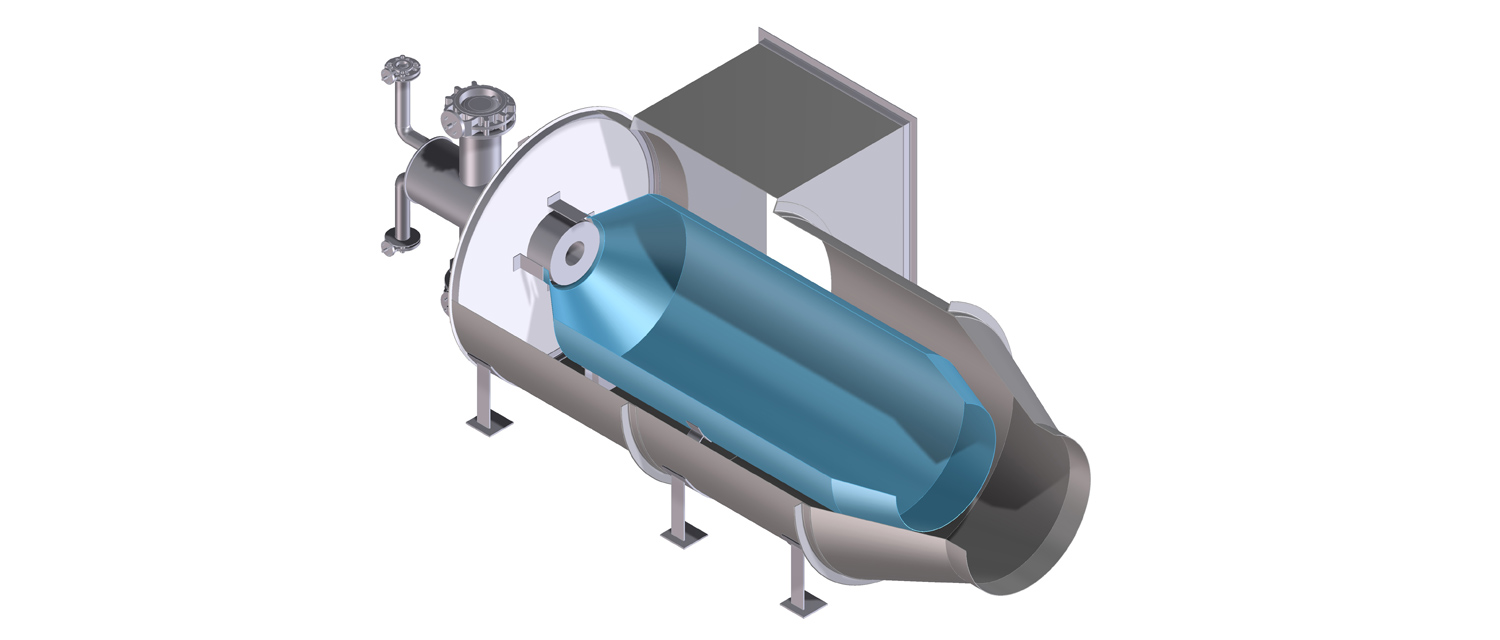

Combustion chamber geometry has been modified over time. Combustion chamber “Separated flow type” concept developed by Novimpianti features the flame pipe completely separated from process flow (picture at the top of this article). In this way we can protect the flame from cold process air, up to the complete oxidation of natural gas; furthermore, we completely avoid any risk of endplate overheating, with quick deterioration of burner and combustion chamber. In our last installations, the system is capable to inject a controlled process air flow into the flame pipe, reducing fresh air amount and optimizing CO and NOx emissions.

Air-to-gas ratio control for a significant gas saving

Air-to-gas ratio plays a key role in emissions control and thermal efficiency: high excess of air means lower flame temperature (i.e. high CO values) and limited humidity content in exhaust. With high amount of fresh air the system cannot work at 0.8 – 1 kgw/kgDA, values that can be reached in more stoichiometric conditions. As commonly known, increasing from 0.4 kgw/kgDA to 0.8 kgw/kgDA means reducing exhaust dry air flow to 50%, with immediate gas saving as shown picture 2.

There are a lot of installations, especially in Europe, with fix combustion air. This means combustion air flow isn’t connected to burner output (like often happens in case of in-line burners). In other cases one actuator opens and closes both gas valve and combustion air valve, thanks to a rigid mechanical connection.

Now there are solutions with electronic connection between gas and combustion air dampers, managed by a safety PLC that takes care of the complete burner control system. It means that safety PLC is connected to all burner devices, from pressure switches to gas valves, from purge procedure to flame control. The result is an intrinsically safe and trouble free system.

Corner and in-line burners

Use in-line or corner type can have a big impact in system lay out. In picture 3 a typical corner burner with its “swirl” flame and in picture 4 a standard inline burner with fix combustion air, very common in old installations. Replacing an in-line burner with a corner one can be complicated, sometimes only possible with largescale rebuilding in burner room, i.e. high cost and long machine shut down.

A smart alternative is replacing old in-line burners designed for fix combustion air with new in-line burners with modulating combustion air. This technology, directly coming from gas turbine postfiring application, has a good turndown with 20% excess of air only. It can be easily installed in the same combustion chamber, with a plug & play solution that cuts the costs of investment, installation and shut down.

In terms of CO emissions, picture 5 shows an example of achievable result.

Concrete results

Novimpianti numbers a few successful references in combustion system upgrade. What described above must be considered as guidelines, since for every mill it is necessary a dedicated preliminary study to choose a customized and profitable solution. The solutions we propose aim at achieving thermal energy savings, reducing emissions to satisfy restrictions in force and maximizing the safety and reliability of combustion system to the updated state-of-the-art installations. All of these with attention to shorten erection and shut down time, for a cost effective modification.

Novimpianti Drying Technology Srl

Novimpianti Drying Technology Srl is an Engineering and Manufacturing Company located in Lucca, Italy, specialized in Tissue Drying, Paper, Board, Ventilation and Environmentally friendly Technology Solutions.

Our main products are:

– Yankee Hoods up to 650°C operating blowing air temperature

– Steam generation by Yankee Hood Exhaust

– Yankee Head Savers

– Heat Recovery Units

– Steam & Condensate Systems for Tissue and Paper Machines, Corrugators

– Dust Removal systems for Tissue Machines, Rewinders and converting lines

– Mist Removal Systems

– Closed Hoods for dryer sections

– Stabilization and Pocket Ventilation

– Building Heating & Ventilation

– Complete Boiler houses

– Cogeneration with Gas Turbine Exhaust

– Auxiliary systems

– Steam Box

– Survey for process Optimization and Energy Saving

– Diagnostic Services, Maintenance and Spare Parts

– Component supply

Yankee hoods installed in the past are very often equipped with burners designed to guarantee drying capacity and high reliability, but with no specific target about efficiency and emissions.

In the last few years, energy and environmental issues became important and drove great design changes. Now it is more correct to speak about “combustion systems” and not simply “burners”. A combustion system is made by: the burner itself; combustion chamber; control system (in particular the control of combustion air flow following variable .0).

The design of the whole combustion system must guarantee the compliance with highly restrictive rules nowadays in force in Europe, North America, Australia. Furthermore, in addition to Country regulation, there are local rules that sometimes require special characteristics, mostly in terms of pollution emissions.

Novimpianti is a primary supplier for the paper industry worldwide

Novimpianti is frequently asked to update existing combustion systems, in order to improve thermal efficiency and respect all restrictions to the exhaust. In this case the first step must be an investigation, to understand the current equipment, fix all targets and help mill management to choose the best strategy. Of course there are many parameters to be considered, like:

» Existing burners and combustion chambers characteristics;

» Maximum necessary power (avoiding useless oversizing);

» Available combustion air temperature (some burners can accept more than 300°C);

» Impact in air system layout;

» CO and NOx limits (e.g. 50mgCO /Nm3 @17%O2);

» Burner turndown (usually from 10:1 to 20:1);

» Combustion air-to-gas ratio control;

» In-line or corner burner;

» Process air injection into corner burner combustion chamber.

Combustion chamber – latest developments

Combustion chamber geometry has been modified over time. Combustion chamber “Separated flow type” concept developed by Novimpianti features the flame pipe completely separated from process flow (picture at the top of this article). In this way we can protect the flame from cold process air, up to the complete oxidation of natural gas; furthermore, we completely avoid any risk of endplate overheating, with quick deterioration of burner and combustion chamber. In our last installations, the system is capable to inject a controlled process air flow into the flame pipe, reducing fresh air amount and optimizing CO and NOx emissions.

Air-to-gas ratio control for a significant gas saving

Air-to-gas ratio plays a key role in emissions control and thermal efficiency: high excess of air means lower flame temperature (i.e. high CO values) and limited humidity content in exhaust. With high amount of fresh air the system cannot work at 0.8 – 1 kgw/kgDA, values that can be reached in more stoichiometric conditions. As commonly known, increasing from 0.4 kgw/kgDA to 0.8 kgw/kgDA means reducing exhaust dry air flow to 50%, with immediate gas saving as shown picture 2.

There are a lot of installations, especially in Europe, with fix combustion air. This means combustion air flow isn’t connected to burner output (like often happens in case of in-line burners). In other cases one actuator opens and closes both gas valve and combustion air valve, thanks to a rigid mechanical connection.

Now there are solutions with electronic connection between gas and combustion air dampers, managed by a safety PLC that takes care of the complete burner control system. It means that safety PLC is connected to all burner devices, from pressure switches to gas valves, from purge procedure to flame control. The result is an intrinsically safe and trouble free system.

Corner and in-line burners

Use in-line or corner type can have a big impact in system lay out. In picture 3 a typical corner burner with its “swirl” flame and in picture 4 a standard inline burner with fix combustion air, very common in old installations. Replacing an in-line burner with a corner one can be complicated, sometimes only possible with largescale rebuilding in burner room, i.e. high cost and long machine shut down.

A smart alternative is replacing old in-line burners designed for fix combustion air with new in-line burners with modulating combustion air. This technology, directly coming from gas turbine postfiring application, has a good turndown with 20% excess of air only. It can be easily installed in the same combustion chamber, with a plug & play solution that cuts the costs of investment, installation and shut down.

In terms of CO emissions, picture 5 shows an example of achievable result.

Concrete results

Novimpianti numbers a few successful references in combustion system upgrade. What described above must be considered as guidelines, since for every mill it is necessary a dedicated preliminary study to choose a customized and profitable solution. The solutions we propose aim at achieving thermal energy savings, reducing emissions to satisfy restrictions in force and maximizing the safety and reliability of combustion system to the updated state-of-the-art installations. All of these with attention to shorten erection and shut down time, for a cost effective modification.

Products

Absorbency testers, Aeration and deaeration plants, Air conditioning plants, Air heaters, Assembling, Ball valves, Basis weight valves, Blade valves, Butterfly valves, Centrifugal pumps, Condensate plants, Consultancy services, Control instruments and systems, Dosing pumps, Dryers and drying plants, Drying hoods, Dust extractors, Energy Saving, Exhausters, Fans, Heat exchangers, Heat recovery systems, High pressure pumps, Industrial technical items, Liquid level transmitters, Maintenance, Measuring and control equipments, Measuring instruments and systems, Medium consistence pumps, Meters equipments, Nozzles, Paper machines, Paper Mills plants, Paperboard machines, Pressure transmitters, Process controls for paper machines, Project planning, Pumps, Recovery plants, Spare parts, Standard chemical pumps, Steam and condensate systems, Steam injectors, Steam valves, Technical service, Temperature instruments, Tunnel dryers, Vapour hoods, Ventilation equipments, Yankee hoods .