Since 2005 SABA AUTOMATION has been designing and implementing, in close synergy with its customers, integrated solutions capable of responding to market needs. The company offers customised end-of-line automation solutions for the tissue industry. For this purpose, it manufactures palletising robots, a wide range of transport systems for products and pallets, automatic wrapping machines, labelling machines, and warehouse entry and exit areas. Automatic guided vehicles complete the range of end-of-line solutions. As Alessandro Pollini, Sales Director of SABA AUTOMATION explains – “sharing objectives with customers is not simply selling machines but solutions. Thanks to the know-how acquired in the various sectors where we operate, we examine production flows, products, logistics in the area concerned and in the factory, all the data, etc., understanding how to improve process automation”.

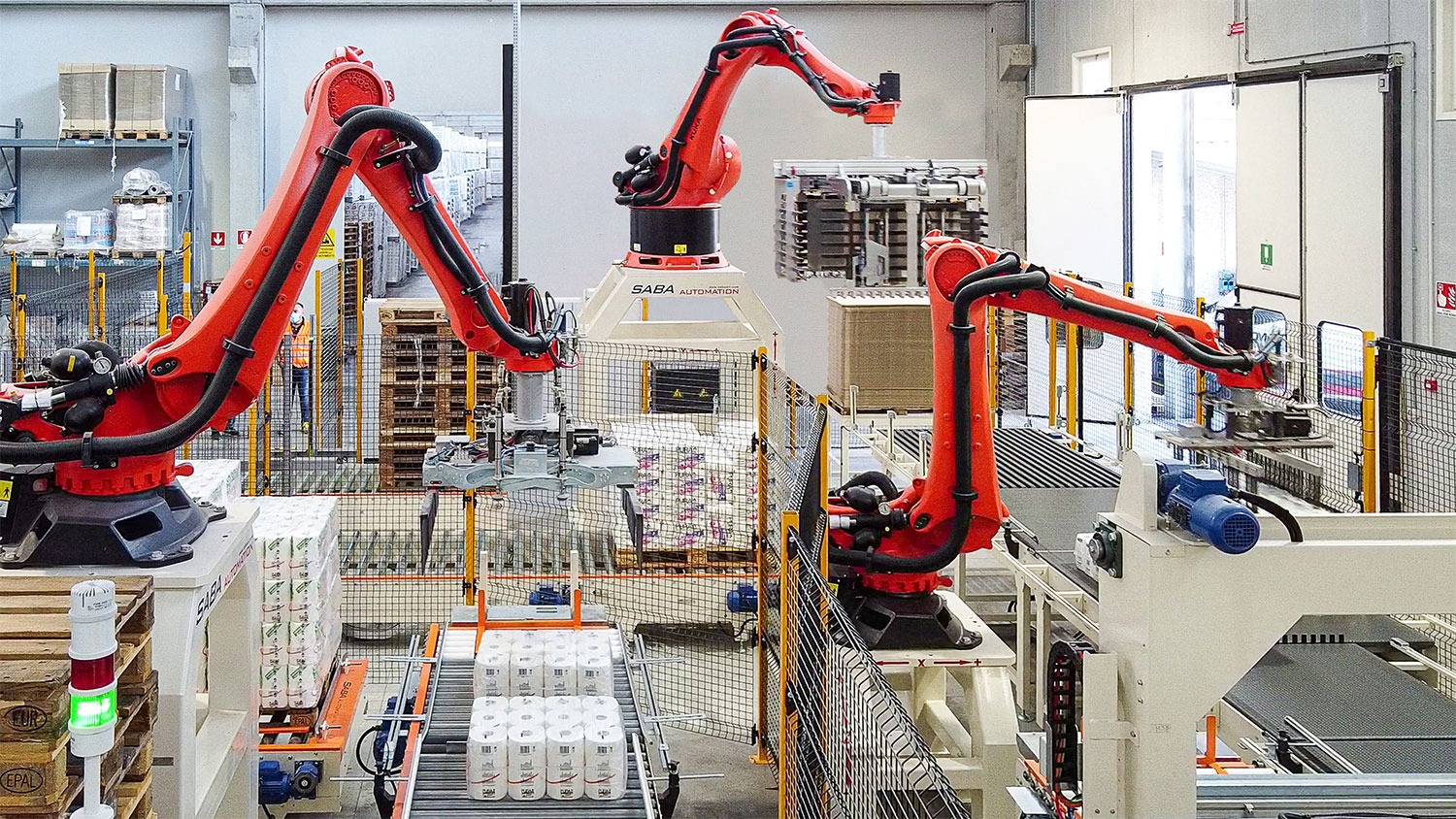

The real “top of the range” are undoubtedly the ZEUS automatic robotic end-of-line systems, designed for palletising products, coming from packaging, carton packing, bundling and bag filling machines, namely folded products (napkins, handkerchiefs, inter-folded paper towels) and rolls (rolls of paper for household and industrial hygiene use). These solutions are extremely fast in terms of cycles per minute and can serve even lines with a very high production output. Particular care has been paid towards design of the pick-up implements both for unpacked and packed tissue products. These special grippers grasp the product without causing any kind of deformation; this drastically improves quality of palletising. All grippers are motorised with the robot’s interpolated axis to ensure adequate handling of such a delicate product as is tissue paper.

We develop technical solutions, according to your production process

The size changeover system adopted is much more accurate than the typical pneumatic systems so that the gripper does not damage the product.

The ZEUS series is divided into two types: P Series and Layer Series. The former is a single anthropomorphic robot, which picks products individually or arranged in rows; the latter consists of a robot (or two robots) that form layers and a second robot for palletising. The latter can pick and place one or more layers simultaneously.

PAL management software has been optimised, and is provided with interfacing to an INDUSTRIAL PC to make line operation easier still and allow for better control over all end-of-line stages. Thanks to the combination of robot and software, SABA AUTOMATION robotised palletising systems offer more advantages in terms of cycle time reduction, adaptability to different products and elimination of downtime. Operators no longer have to deal with heavy palletising work and no longer have to perform size changeover operations since a production order can be called up and uploaded in an instant.

In accordance to the principles of Industry 4.0, this software can be interfaced with the latest management software so that data can be duly exchanged. Digitisation of machines, flexible and automated format changes, remote management and control of production. In addition to solutions featuring anthropomorphic robots, SABA AUTOMATION designs and builds BD CARTESIAN ROBOTS. These are compact solutions, with a high performance, ideal for lines handling paper napkins, handkerchiefs and inter-folded paper towels. Cartesian robots designed to operate in three shifts for 365 days a year, with low maintenance requirements and high efficiency. This series also adopts the software solutions available for the Zeus series.

Constant improvement and development

Despite the pandemic, 2021 – in the same manner as 2020 – has been a very satisfactory year for SABA AUTOMATION. The company has consolidated its presence in the end-of-line market dedicated to the tissue industry. Significant orders were acquired, both nationally and internationally. In order to maintain this “steady growth”, SABA AUTOMATION is giving more attention to support and additional services.

Our team is constantly researching and developing new solutions to facilitate production and use of equipment. Curiosity and the will to become better and better are the driving force of our company. In other words, we never sit back and relax but always look forward. Passion guides us and we want to involve our customers in this attitude.

Reliable and efficient even at a distance. In order to continue to offer maximum support in an international context conditioned by recent events, SABA AUTOMATION has undertaken a series of initiatives aimed at granting its usual reliability and efficiency. To ensure full business continuity, it enhanced its online services: Thanks to these tools, combined with established procedures, the company can now and in the future respond to all service requests from Italy and abroad.

Events and news

● We will be at MIAC in Lucca from October 12th to 14th 2022, where, besides meeting our staff at the stand, it will be possible (by appointment) to visit a company and see SABA AUTOMATION technology at work.

● We will soon be presenting further innovations for end-of-line systems; because only with innovation and a start-up approach can we build our future. Visit our website, our YouTube, LinkedIn, Instagram and Facebook channels… keep in touch.

SABA Automation srl

SABA AUTOMATION offers customised end-of-line automation solutions for the tissue industry.

For this purpose, SABA AUTOMATION manufactures palletizing robots , a wide range of transport systems for products and pallets, automatic wrapping machines, labelling machines, and warehouse entry and exit areas. Automatic guided vehicles complete the range of end-of-line solutions.

As Alessandro Pollini, Sales Director of SABA AUTOMATION explains “Sharing objectives with customers is not simply selling machines but solutions. Thanks to the know-how acquired in the various sectors where we operate, we examine production flows, products, logistics in the area concerned and in the factory, all the data, etc., understanding how to improve process automation.”

Since 2005 SABA AUTOMATION has been designing and implementing, in close synergy with its customers, integrated solutions capable of responding to market needs. The company offers customised end-of-line automation solutions for the tissue industry. For this purpose, it manufactures palletising robots, a wide range of transport systems for products and pallets, automatic wrapping machines, labelling machines, and warehouse entry and exit areas. Automatic guided vehicles complete the range of end-of-line solutions. As Alessandro Pollini, Sales Director of SABA AUTOMATION explains – “sharing objectives with customers is not simply selling machines but solutions. Thanks to the know-how acquired in the various sectors where we operate, we examine production flows, products, logistics in the area concerned and in the factory, all the data, etc., understanding how to improve process automation”.

The real “top of the range” are undoubtedly the ZEUS automatic robotic end-of-line systems, designed for palletising products, coming from packaging, carton packing, bundling and bag filling machines, namely folded products (napkins, handkerchiefs, inter-folded paper towels) and rolls (rolls of paper for household and industrial hygiene use). These solutions are extremely fast in terms of cycles per minute and can serve even lines with a very high production output. Particular care has been paid towards design of the pick-up implements both for unpacked and packed tissue products. These special grippers grasp the product without causing any kind of deformation; this drastically improves quality of palletising. All grippers are motorised with the robot’s interpolated axis to ensure adequate handling of such a delicate product as is tissue paper.

We develop technical solutions, according to your production process

The size changeover system adopted is much more accurate than the typical pneumatic systems so that the gripper does not damage the product.

The ZEUS series is divided into two types: P Series and Layer Series. The former is a single anthropomorphic robot, which picks products individually or arranged in rows; the latter consists of a robot (or two robots) that form layers and a second robot for palletising. The latter can pick and place one or more layers simultaneously.

PAL management software has been optimised, and is provided with interfacing to an INDUSTRIAL PC to make line operation easier still and allow for better control over all end-of-line stages. Thanks to the combination of robot and software, SABA AUTOMATION robotised palletising systems offer more advantages in terms of cycle time reduction, adaptability to different products and elimination of downtime. Operators no longer have to deal with heavy palletising work and no longer have to perform size changeover operations since a production order can be called up and uploaded in an instant.

In accordance to the principles of Industry 4.0, this software can be interfaced with the latest management software so that data can be duly exchanged. Digitisation of machines, flexible and automated format changes, remote management and control of production. In addition to solutions featuring anthropomorphic robots, SABA AUTOMATION designs and builds BD CARTESIAN ROBOTS. These are compact solutions, with a high performance, ideal for lines handling paper napkins, handkerchiefs and inter-folded paper towels. Cartesian robots designed to operate in three shifts for 365 days a year, with low maintenance requirements and high efficiency. This series also adopts the software solutions available for the Zeus series.

Constant improvement and development

Despite the pandemic, 2021 – in the same manner as 2020 – has been a very satisfactory year for SABA AUTOMATION. The company has consolidated its presence in the end-of-line market dedicated to the tissue industry. Significant orders were acquired, both nationally and internationally. In order to maintain this “steady growth”, SABA AUTOMATION is giving more attention to support and additional services.

Our team is constantly researching and developing new solutions to facilitate production and use of equipment. Curiosity and the will to become better and better are the driving force of our company. In other words, we never sit back and relax but always look forward. Passion guides us and we want to involve our customers in this attitude.

Reliable and efficient even at a distance. In order to continue to offer maximum support in an international context conditioned by recent events, SABA AUTOMATION has undertaken a series of initiatives aimed at granting its usual reliability and efficiency. To ensure full business continuity, it enhanced its online services: Thanks to these tools, combined with established procedures, the company can now and in the future respond to all service requests from Italy and abroad.

Events and news

● We will be at MIAC in Lucca from October 12th to 14th 2022, where, besides meeting our staff at the stand, it will be possible (by appointment) to visit a company and see SABA AUTOMATION technology at work.

● We will soon be presenting further innovations for end-of-line systems; because only with innovation and a start-up approach can we build our future. Visit our website, our YouTube, LinkedIn, Instagram and Facebook channels… keep in touch.

Products

Anthropomorphosis robots, Conveying equipments, Conveying systems for paper reels, LGV laser guided vehicles, Palletiser - Palletising, Palletising lines, Project planning.