Designing and producing energy generation systems for the industrial sector requires balancing production needs and energy availability, in a perspective that must look at the energy mix as the best possible solution. Solar Turbines (Caterpillar Group), historical manufacturer of energy generation systems for the industrial sector and present all over the world with more than 16,000 gas turbines installed, is already ready to face current and future scenarios.

Powering the future through innovative energy solutions

CHP and fluctuations in the price of energy

The international geopolitical situation and the recovery of economic activities are causing sudden and unexpected fluctuations in the prices of methane gas, electricity and CO2, putting the entire industry in difficulty, especially the energy intensive manufacturing sectors such as that of paper production. The pulp & paper sector, including the tissue production sector, has been using CHP (Combined Heat and Power) technology for years. Solar demonstrates how this, also thanks to the application of its highly technological gas turbines, continues to be the most effective and efficient solution, especially in a period of strong tensions on the price of energy.

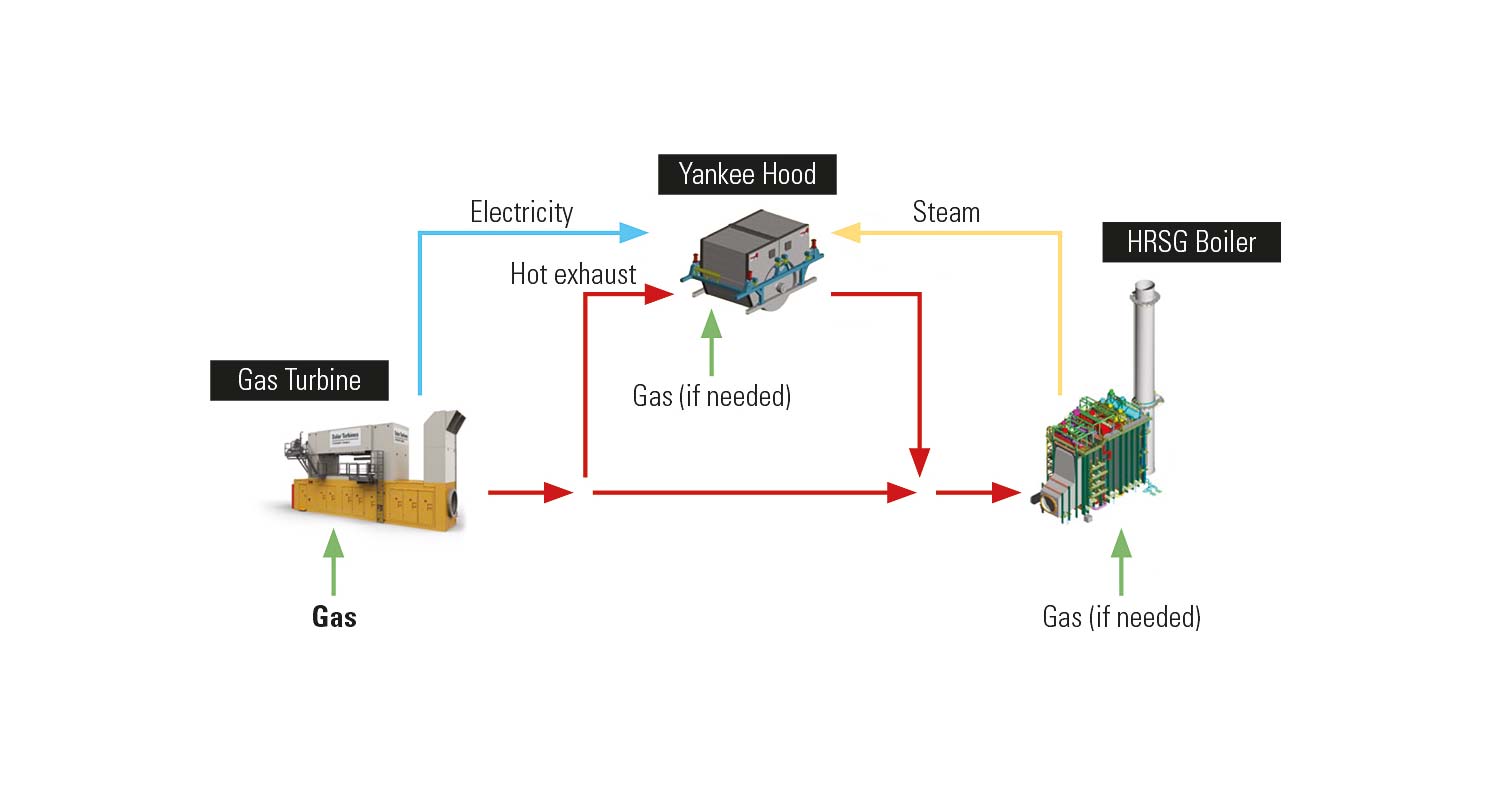

Solar gas turbines with direct drying system are particularly suitable to meet the needs of the tissue sector. They use the exhaustgases of the turbine directly in the drying section of the paper machine and, as Benoît Fécamp, EAME Strategic Growth and Market Development Manager of Solar Turbines explains: “they guarantee a number of advantages: a clean exhaust end product, low emissions and, above all, a significant increase in the energy efficiency of the system, which is between 80% and 90%. The direct drying system allows a reliable and stable production of electricity and heat, and also guarantees maximum flexibility, covering all operating modes of a paper mill”. One important fact for paper manufacturers is also the possibility of retrofitting. “Our GTs can be installed on both new plants and on existing tissue machines”.

The economic sustainability of CHP

Already under normal market conditions, the comparison between a conventional generation system and a CHP system demonstrates the advantage of the latter. With fluctuating markets and high energy and CO2 prices, like what has been taking place in Europe since late 2021, the figures prove that relying on CHP technology still offers a tissue paper mill considerable savings.

Cash flow simulation Q2-2022

Taking as an example a CHP system with a T70 direct drying turbine and a production of 70,000 t/y, with a demand of 9 MWe and 9.5 t/h of steam at around 15 barg, in a context of prices at the beginning of 2022 around € 0.240/kWh for electricity, € 0.8/Sm3 for natural gas, and 89 t/CO2 per EUA emission quota, an annual primary savings (free cash from operations) of € 3,381,000 was calculated.

Cash flow simulation Q4-2024

Even assuming, as analysts argue, a lowering of energy costs within the next two years, with prices in 2024 of € 0.90/kWh for electricity and € 0.37/Sm3 for gas, and assuming an increase in the cost of CO2 as a result of sustainable development policies, with an EUA of 93 t/CO2, the savings would amount to € 3,704,000 per year.

Trends of the future: hydrogen and digitization

The vision of Solar Turbines is not limited to the present, however, because the energy scenario is destined to change. Mixing energy sources will be increasingly necessary, especially in view of a greater diffusion of renewables which are not predictable.

“Our gaze is directed to the future – said Fécamp – to the trends of tomorrow which are hydrogen, biogas, digital and CCUS (Carbon Capture, Utilization and Storage), topics which paper producers are watching with interest”.

Solar’s experience in hydrogen technology, which began with the first H2 turbine models in 1985, already numbers 55 operating units with over 2 million hours of operation.

“Our technologies are already equipped to operate with gas mixtures with 20% H2 content, which is the maximum concentration expected to circulate in the pipelines. Our goal is to arrive at SoloNOx DLE gas turbine models capable of burning 100% hydrogen”. Another key issue is the digitization of the plant. “Our digital systems allow you to communicate with the outside world and adjust the operation of the CHP plant and the gas turbine according not only to the demands of the production cycle but also to external factors such as, precisely, the cost of energy sources. This – Fécamp concluded – will allow the paper mill to do what is needed when it is needed”. In the most economically and eco-friendliest way.

Innovative gas turbine solutions

Solar Turbines Switzerland SAGL

Solar® Turbines installed more than 1.6 GWe in the Pulp & Paper industry worldwide which correspond to more than 150 installations.

In particular we have been providing gas turbines packages for integrated cogeneration plants in the tissue industry on six continents.

Our packages superior reliability and our granular Customer Services organization enables us to be your supplier of choice everywhere in the world.

Solar® Turbines is a leading manufacturer of mid-range industrial gas turbines (3.5 to 21.7 MW). More than 15,000 Solar units are operating in 100 countries around the world. We are part of Caterpillar Inc., the world’s leading manufacturer of construction and mining equipment, diesel and natural gas reciprocating engines and industrial gas turbines.

Designing and producing energy generation systems for the industrial sector requires balancing production needs and energy availability, in a perspective that must look at the energy mix as the best possible solution. Solar Turbines (Caterpillar Group), historical manufacturer of energy generation systems for the industrial sector and present all over the world with more than 16,000 gas turbines installed, is already ready to face current and future scenarios.

Powering the future through innovative energy solutions

CHP and fluctuations in the price of energy

The international geopolitical situation and the recovery of economic activities are causing sudden and unexpected fluctuations in the prices of methane gas, electricity and CO2, putting the entire industry in difficulty, especially the energy intensive manufacturing sectors such as that of paper production. The pulp & paper sector, including the tissue production sector, has been using CHP (Combined Heat and Power) technology for years. Solar demonstrates how this, also thanks to the application of its highly technological gas turbines, continues to be the most effective and efficient solution, especially in a period of strong tensions on the price of energy.

Solar gas turbines with direct drying system are particularly suitable to meet the needs of the tissue sector. They use the exhaustgases of the turbine directly in the drying section of the paper machine and, as Benoît Fécamp, EAME Strategic Growth and Market Development Manager of Solar Turbines explains: “they guarantee a number of advantages: a clean exhaust end product, low emissions and, above all, a significant increase in the energy efficiency of the system, which is between 80% and 90%. The direct drying system allows a reliable and stable production of electricity and heat, and also guarantees maximum flexibility, covering all operating modes of a paper mill”. One important fact for paper manufacturers is also the possibility of retrofitting. “Our GTs can be installed on both new plants and on existing tissue machines”.

The economic sustainability of CHP

Already under normal market conditions, the comparison between a conventional generation system and a CHP system demonstrates the advantage of the latter. With fluctuating markets and high energy and CO2 prices, like what has been taking place in Europe since late 2021, the figures prove that relying on CHP technology still offers a tissue paper mill considerable savings.

Cash flow simulation Q2-2022

Taking as an example a CHP system with a T70 direct drying turbine and a production of 70,000 t/y, with a demand of 9 MWe and 9.5 t/h of steam at around 15 barg, in a context of prices at the beginning of 2022 around € 0.240/kWh for electricity, € 0.8/Sm3 for natural gas, and 89 t/CO2 per EUA emission quota, an annual primary savings (free cash from operations) of € 3,381,000 was calculated.

Cash flow simulation Q4-2024

Even assuming, as analysts argue, a lowering of energy costs within the next two years, with prices in 2024 of € 0.90/kWh for electricity and € 0.37/Sm3 for gas, and assuming an increase in the cost of CO2 as a result of sustainable development policies, with an EUA of 93 t/CO2, the savings would amount to € 3,704,000 per year.

Trends of the future: hydrogen and digitization

The vision of Solar Turbines is not limited to the present, however, because the energy scenario is destined to change. Mixing energy sources will be increasingly necessary, especially in view of a greater diffusion of renewables which are not predictable.

“Our gaze is directed to the future – said Fécamp – to the trends of tomorrow which are hydrogen, biogas, digital and CCUS (Carbon Capture, Utilization and Storage), topics which paper producers are watching with interest”.

Solar’s experience in hydrogen technology, which began with the first H2 turbine models in 1985, already numbers 55 operating units with over 2 million hours of operation.

“Our technologies are already equipped to operate with gas mixtures with 20% H2 content, which is the maximum concentration expected to circulate in the pipelines. Our goal is to arrive at SoloNOx DLE gas turbine models capable of burning 100% hydrogen”. Another key issue is the digitization of the plant. “Our digital systems allow you to communicate with the outside world and adjust the operation of the CHP plant and the gas turbine according not only to the demands of the production cycle but also to external factors such as, precisely, the cost of energy sources. This – Fécamp concluded – will allow the paper mill to do what is needed when it is needed”. In the most economically and eco-friendliest way.

Innovative gas turbine solutions

Products

Cogeneration, Cogeneration systems + paper drying applications, Energy Saving, Software, Turbine Cabins.