Toscotec has been awarded a new turnkey supply order for an AHEAD 2.2 tissue line by the Bangladeshi consumer goods manufacturer City Group who is entering the tissue market. The new tissue mill will be erected in Hoshendi Economic Zone near Dhaka, and it is planned to start production in 2023. “When we set out to enter the tissue market, we did a careful evaluation of machinery manufacturers at global level looking for a supplier of turnkey projects who could also provide all the assistance we needed to succeed – says Md. Imran Uddin, Director of Planning & Business Development at City Group. We decided on Toscotec because they offered the highest guarantee of advanced technology and wide experience in giving full-on support to newcomers in tissue” – added Md. Imran Uddin.

Challenge the status quo

The turnkey supply: a complete tissue plant, one single supplier

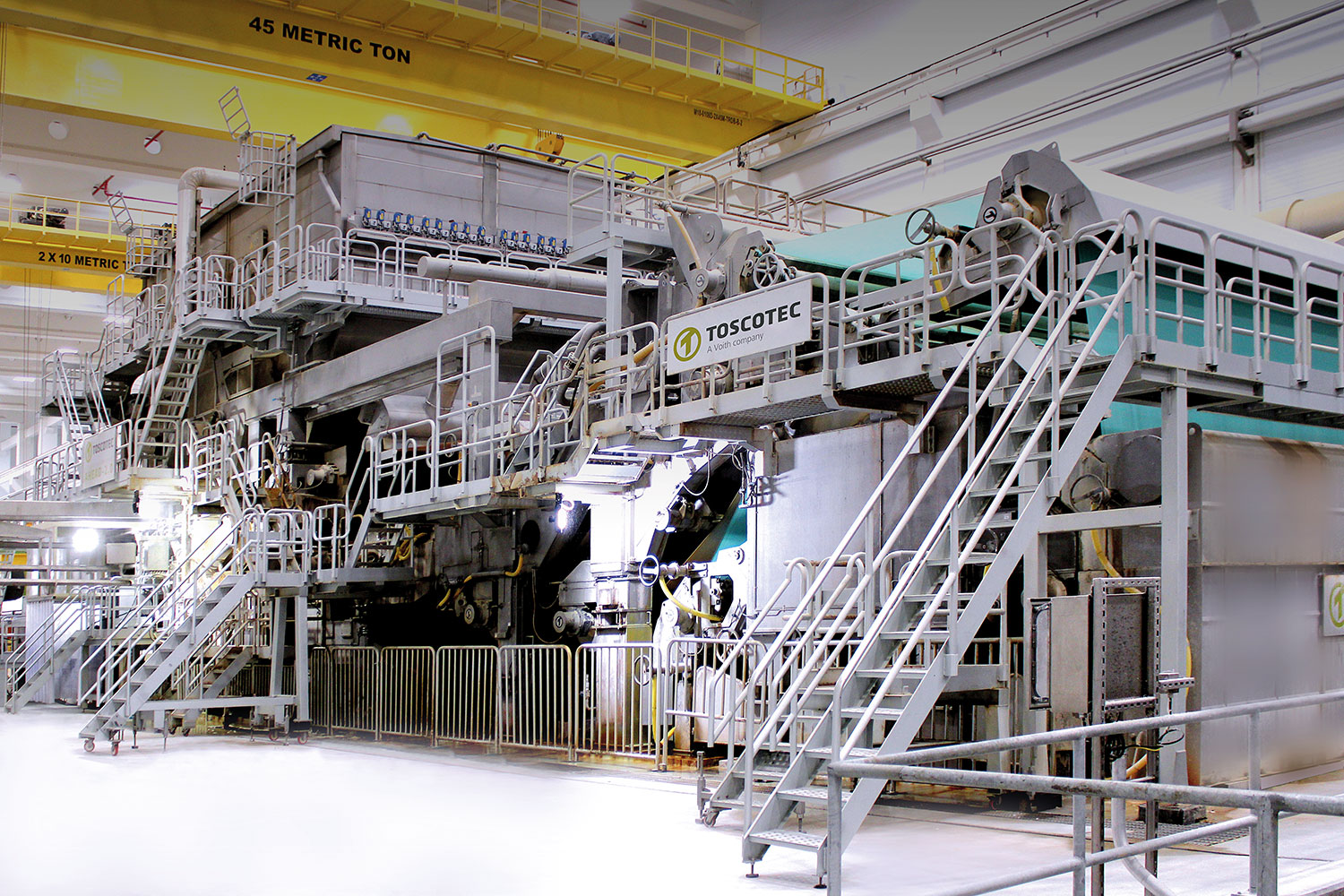

Toscotec’s turnkey supply to City Group encompasses the entire tissue making plant, from the complete stock preparation and fiber recovery systems, the patented TT SAF® Short Approach Flow with double dilution, the full electrification plant, to Toscotec’s proprietary control system, and all associated auxiliary systems. The AHEAD 2.2 machine has a design speed of 2,200 m/min and a production capacity of over 40,000 tpy.

It is designed for superior drying efficiency through the combination of the latest generation design of both TT NextPress shoe press and TT SYD Steel Yankee Dryer, as well as TT Hood with multistage energy recovery. Toscotec will also deliver the new OPTIMA 2200 slitter rewinder designed to preserve the bulk and softness of the mother reel. City Group ordered an extensive service package including detailed engineering, erection supervision, training commissioning, start-up assistance, and YES-CONNECT-VISION Augmented Reality remote assistance system.

Undisputed market leadership rooted in unique capabilities

Since 2015, Toscotec has sold more than 20 turnkey tissue projects across the world. Its experience in managing complex projects such as turnkeys has been built by over 20 years and more than 30 different projects. This kind of expertise is rooted in two essential assets. The first is a large team of in-house professionals that work on the design of the complete plant, from the fibre and water processes, the plant layout, the entire tissue machine including the electrical plant and control system, up to the rewinder. Only machinery manufacturers who have such considerable internal resources have the actual capability to manage turnkey projects. The second asset is the ability to provide paper mills with the necessary technical expertise, support and experience related to every detail of the turnkey supply, so that they can stay focused on their core business and significantly reduce the fixed costs linked to an in-house technical department. As a result, the turnkey supplier must have a full team of experts coming into play to deliver on every single technical task, including engineering, project management, equipment selection, coordination of sub-suppliers, manufacturing, pre-erection, logistics, on-site erection, commissioning, and start-up, up to the achievement of guaranteed performances. Based on these unique capabilities and experience, Toscotec is recognized as the global leading supplier of turnkey tissue projects.

A fully customized engineering design as fil rouge of Toscotec’s projects

Toscotec’s turnkey supplies have been delivered and installed in four continents, including Asia, Africa, America, and Europe, often requiring complex logistic operations in remote areas, as well as compliance to local machinery manufacturing standards. Their one common denominator is fully customized engineering design. Toscotec’s renowned flexibility and constant communication with customers play an important role in the successful completion of complex projects. Turnkey projects often are greenfield supplies that start with the erection of a brand-new building, but they may also be a new tissue line to be installed inside an existing building. If this is the case, Toscotec takes design customization to a whole new level, as it must consider the constraints of the existing building, or – as it is for turnkey rebuild projects – of the existing tissue machine.

Toscotec’s rebuilds effectively extend the life of existing plants and allow tissue manufacturers to achieve a high degree of optimization with a limited budget.

Capitalizing on turnkey supplies: plenty of choice

Turnkey projects offer so many advantages to tissue producers that they truly are left spoiled for choice. The guarantee of the supplier’s full accountability vis-à-vis the entire scope is acknowledged by paper mills as one of the key benefits. Toscotec has consistently demonstrated its ability to successfully manage complex projects and deliver on the demanding performances of the entire plant.

The fact that many of its turnkey contracts are repeat orders is clear evidence of this ability, which is also incremented with the experience gained on every new project.

A second key benefit is represented by the energy efficiency focus across the entire plant. The full width of the scope allows Toscotec to push the envelope on the design and choice of equipment of the production line and deliver the highest efficiency. Toscotec delivers a third key advantage as turnkey supplier in offering complete packages of stock preparation and fiber recovery systems as well as digital solutions that are entirely designed and manufactured by Voith.

Toscotec

Since its foundation in 1948, Toscotec specializes in the design and manufacture of turnkey projects, complete machines, plant rebuilds and single equipment for the tissue and paper & board industries.

Headquartered in Lucca, with affiliates and service centres in China and North America, Toscotec provides state-of-the-art technology and customized solutions to leading paper producers around the world.

Our technology aims at maximum production efficiency, reduced energy consumption and operating costs, finished products of the highest quality and respect for the environment.

From 30th April 2020, Toscotec is part of the Voith Group.

Toscotec has been awarded a new turnkey supply order for an AHEAD 2.2 tissue line by the Bangladeshi consumer goods manufacturer City Group who is entering the tissue market. The new tissue mill will be erected in Hoshendi Economic Zone near Dhaka, and it is planned to start production in 2023. “When we set out to enter the tissue market, we did a careful evaluation of machinery manufacturers at global level looking for a supplier of turnkey projects who could also provide all the assistance we needed to succeed – says Md. Imran Uddin, Director of Planning & Business Development at City Group. We decided on Toscotec because they offered the highest guarantee of advanced technology and wide experience in giving full-on support to newcomers in tissue” – added Md. Imran Uddin.

Challenge the status quo

The turnkey supply: a complete tissue plant, one single supplier

Toscotec’s turnkey supply to City Group encompasses the entire tissue making plant, from the complete stock preparation and fiber recovery systems, the patented TT SAF® Short Approach Flow with double dilution, the full electrification plant, to Toscotec’s proprietary control system, and all associated auxiliary systems. The AHEAD 2.2 machine has a design speed of 2,200 m/min and a production capacity of over 40,000 tpy.

It is designed for superior drying efficiency through the combination of the latest generation design of both TT NextPress shoe press and TT SYD Steel Yankee Dryer, as well as TT Hood with multistage energy recovery. Toscotec will also deliver the new OPTIMA 2200 slitter rewinder designed to preserve the bulk and softness of the mother reel. City Group ordered an extensive service package including detailed engineering, erection supervision, training commissioning, start-up assistance, and YES-CONNECT-VISION Augmented Reality remote assistance system.

Undisputed market leadership rooted in unique capabilities

Since 2015, Toscotec has sold more than 20 turnkey tissue projects across the world. Its experience in managing complex projects such as turnkeys has been built by over 20 years and more than 30 different projects. This kind of expertise is rooted in two essential assets. The first is a large team of in-house professionals that work on the design of the complete plant, from the fibre and water processes, the plant layout, the entire tissue machine including the electrical plant and control system, up to the rewinder. Only machinery manufacturers who have such considerable internal resources have the actual capability to manage turnkey projects. The second asset is the ability to provide paper mills with the necessary technical expertise, support and experience related to every detail of the turnkey supply, so that they can stay focused on their core business and significantly reduce the fixed costs linked to an in-house technical department. As a result, the turnkey supplier must have a full team of experts coming into play to deliver on every single technical task, including engineering, project management, equipment selection, coordination of sub-suppliers, manufacturing, pre-erection, logistics, on-site erection, commissioning, and start-up, up to the achievement of guaranteed performances. Based on these unique capabilities and experience, Toscotec is recognized as the global leading supplier of turnkey tissue projects.

A fully customized engineering design as fil rouge of Toscotec’s projects

Toscotec’s turnkey supplies have been delivered and installed in four continents, including Asia, Africa, America, and Europe, often requiring complex logistic operations in remote areas, as well as compliance to local machinery manufacturing standards. Their one common denominator is fully customized engineering design. Toscotec’s renowned flexibility and constant communication with customers play an important role in the successful completion of complex projects. Turnkey projects often are greenfield supplies that start with the erection of a brand-new building, but they may also be a new tissue line to be installed inside an existing building. If this is the case, Toscotec takes design customization to a whole new level, as it must consider the constraints of the existing building, or – as it is for turnkey rebuild projects – of the existing tissue machine.

Toscotec’s rebuilds effectively extend the life of existing plants and allow tissue manufacturers to achieve a high degree of optimization with a limited budget.

Capitalizing on turnkey supplies: plenty of choice

Turnkey projects offer so many advantages to tissue producers that they truly are left spoiled for choice. The guarantee of the supplier’s full accountability vis-à-vis the entire scope is acknowledged by paper mills as one of the key benefits. Toscotec has consistently demonstrated its ability to successfully manage complex projects and deliver on the demanding performances of the entire plant.

The fact that many of its turnkey contracts are repeat orders is clear evidence of this ability, which is also incremented with the experience gained on every new project.

A second key benefit is represented by the energy efficiency focus across the entire plant. The full width of the scope allows Toscotec to push the envelope on the design and choice of equipment of the production line and deliver the highest efficiency. Toscotec delivers a third key advantage as turnkey supplier in offering complete packages of stock preparation and fiber recovery systems as well as digital solutions that are entirely designed and manufactured by Voith.

Products

Drying cylinders, Drying hoods, Dust extractors, Energy Saving, Heat recovery systems, Paper machines, Paperboard machines, Presses, Rewinders, Spare parts, Steam and condensate systems, Stock preparation systems, Winders, Yankee cylinders, Yankee hoods .