At the beginning of its history, MacDue produced only standalone machines. A relationship of trust was built on this offer with customers who, however, had to turn to other companies to complete the line. With the gradual transition from a family business to a managerial one, we decided to expand our offer to cover every aspect of product handling. Having a single point of contact for the entire system has significant advantages for the customer. On the other hand, it poses new challenges to the supplier company: potential problems and extra variables that require an adequate structure and reliable after-sales service. The challenge we set ourselves years ago was to offer our customers “turnkey” lines, up to the wrapper. It was a complex work that allowed us to gain trust and respectability not only as packaging specialists but also as a reality capable of creating complete lines in multiple sectors. To achieve this, we have made important structural changes: we have improved planning, production reports and the management of internal spaces.

Starting from customer’s needs, we develop projects that allow us to manage products from the beginning to the end of line

Most of the work was taken over by the technical department, whose challenge was the creation of compact and economically competitive solutions. The technologies deployed for customers in the industrial sectors are usually different from those applied to customers in the consumer sectors. There are few realities of the second type that have needs similar to those of the first; most consumer customers need flexibility and speed in product management. These needs have forced us to study customized solutions. These flexibility requirements often also translate into changes to be made in real time during the customer’s normal operations. Aware of this need, we are creating custom software that allows you to use the lines intuitively and make quick changes to the pallet configuration.

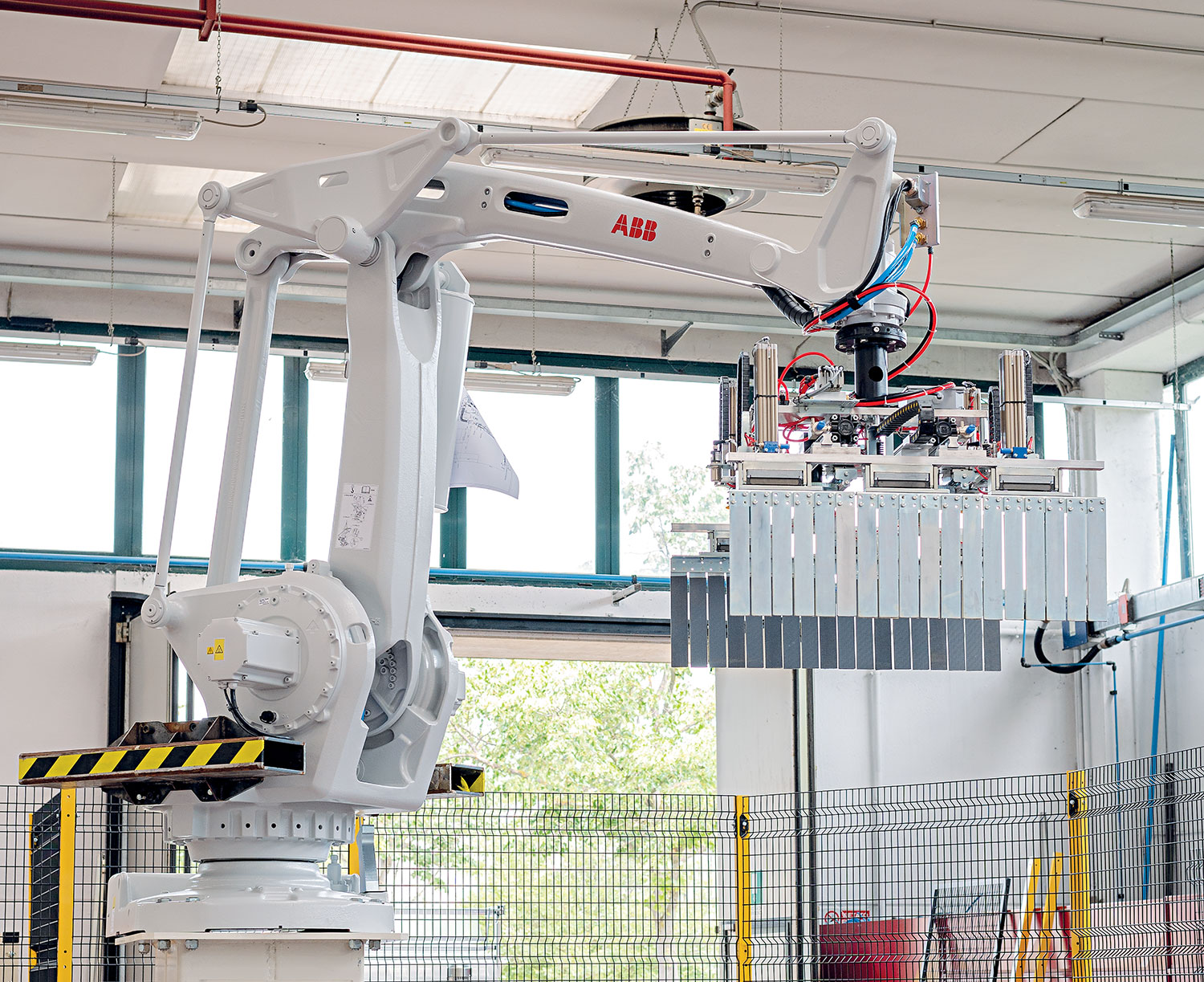

When we collaborate with a customer for the design of a complete line, we pay particular attention to the key element of palletization: the robot grippers. This is a very important component because it can negatively impact the state of the packaging and the construction of the pallet. This is why we design the grippers internally so that they are less invasive in the treatment of the product, resulting more precise and delicate.

Today we are proud to be able to support our customers in the realization of complete projects, which do not neglect the end of line and instead guarantee efficient product management. The constant commitment to the selection and training of qualified resources is rewarding us with the development of solutions that are able to satisfy the needs of customers in compliance with the design constraints.

MacDue

MacDue was established in 1981 in Bologna, the Italian Packaging Valley.

Today MacDue is a leading manufacturer of automated packaging lines for tissue products (paper tissue rolls and folded products), EPS and XPS insulating panels, and thermoformed products such as trays, plates, and cups. With about 6,800 machines installed worldwide, MacDue offers a complete service including consulting, design, project management, manufacturing, installation and after-sales service for its packaging lines and machines, which perfectly fit with the customer’s production process and layout. MacDue is globally connected with an extensive network of agents and dealers, one sales and service branch in North America and one production site in India that manufactures machines for the local market.

At the beginning of its history, MacDue produced only standalone machines. A relationship of trust was built on this offer with customers who, however, had to turn to other companies to complete the line. With the gradual transition from a family business to a managerial one, we decided to expand our offer to cover every aspect of product handling. Having a single point of contact for the entire system has significant advantages for the customer. On the other hand, it poses new challenges to the supplier company: potential problems and extra variables that require an adequate structure and reliable after-sales service. The challenge we set ourselves years ago was to offer our customers “turnkey” lines, up to the wrapper. It was a complex work that allowed us to gain trust and respectability not only as packaging specialists but also as a reality capable of creating complete lines in multiple sectors. To achieve this, we have made important structural changes: we have improved planning, production reports and the management of internal spaces.

Starting from customer’s needs, we develop projects that allow us to manage products from the beginning to the end of line

Most of the work was taken over by the technical department, whose challenge was the creation of compact and economically competitive solutions. The technologies deployed for customers in the industrial sectors are usually different from those applied to customers in the consumer sectors. There are few realities of the second type that have needs similar to those of the first; most consumer customers need flexibility and speed in product management. These needs have forced us to study customized solutions. These flexibility requirements often also translate into changes to be made in real time during the customer’s normal operations. Aware of this need, we are creating custom software that allows you to use the lines intuitively and make quick changes to the pallet configuration.

When we collaborate with a customer for the design of a complete line, we pay particular attention to the key element of palletization: the robot grippers. This is a very important component because it can negatively impact the state of the packaging and the construction of the pallet. This is why we design the grippers internally so that they are less invasive in the treatment of the product, resulting more precise and delicate.

Today we are proud to be able to support our customers in the realization of complete projects, which do not neglect the end of line and instead guarantee efficient product management. The constant commitment to the selection and training of qualified resources is rewarding us with the development of solutions that are able to satisfy the needs of customers in compliance with the design constraints.

Products

Handling Systems, Packaging machines for paper products, Palletiser - Palletising.