The common concept design of creping blade holders has always narrowed down the choices to just two main possibilities: rigid or flexible, both with their strengths and weaknesses. But what if a rigid doctoring system could boast the profiling advantages of a flexible one? Worldwide known for its self-profiling flexible blade holders, Oradoc has recently patented a brand-new, innovative doctoring system that deserves a unique place in creping history: OraLockTM, the perfect fit for all Yankee cylinders.

“As a company we have ventured into a segment in which we had never thought of deepening the application possibilities, so far. Our installations in the world are mainly flexible, but with this new product we want to consolidate our presence also in the rigid market with a disruptive solution” – says Mr. Maurizio Tomei, Oradoc Sales and Customer Care Manager.

A wide range of integrated solutions for the tissue industry, specifically conceived to meet the needs of each production line

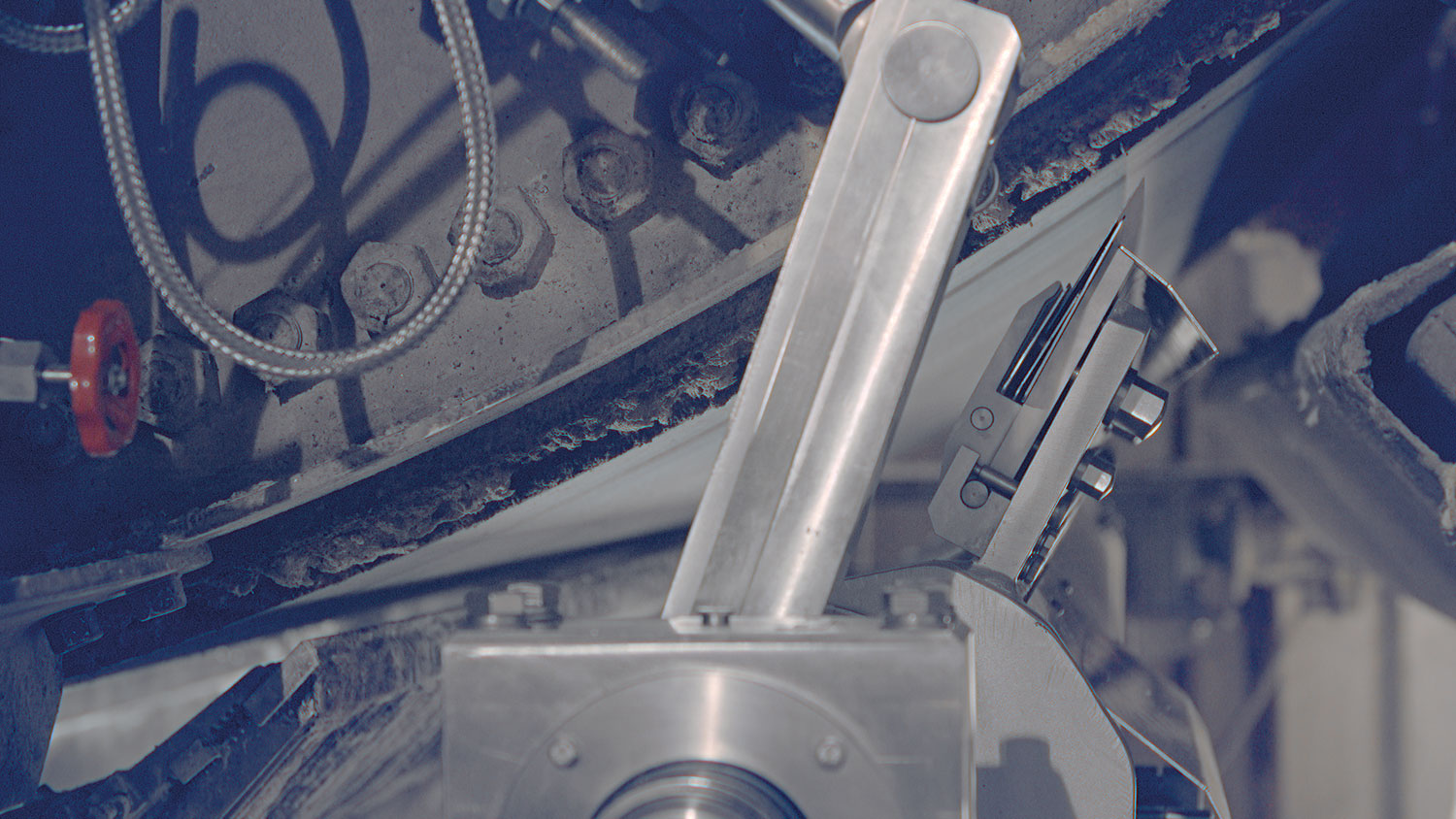

It took more than 3 years of R&D activities carried out by Oradoc engineers, including scale and full-size prototypes, off-line static tests and continuously running machine monitoring, to conceive, design and test this state-of-the-art creping solution.

“Our research and development department is rightfully proud to have achieved a great result in coming up with such a groundbreaking blade holder – explains Mr. Andrea Orlandini, Oradoc Operations Manager. We’ve worked on this system a lot and the final product really meets our expectations and – what’s even most important – it represents the perfect answer to our customers’ needs!”. But no innovation is worth adopting until its usefulness is proven: Oradoc found in Sofidel the perfect partner to be involved in this ambitious project, as Sofidel allowed for the pilot installation to take place in its “Soffass Cartiera Via Giuseppe Lazzareschi” plant (formerly known as Delicarta Paper Mill).

The Sofidel Group is one of the leading manufacturers of paper for hygienic and domestic use worldwide. Established in 1966, the Group has subsidiaries in 12 countries – Italy, Spain, the UK, France, Belgium, Germany, Sweden, Poland, Hungary, Greece, Romania and the USA, with more than 6,000 employees, net sales of 1,919 million Euros (2019) and a production capacity of over one million tons per year (1,308,000 tons in 2019). A member of the UN Global Compact and the international WWF Climate Savers program, the Sofidel Group considers sustainability a strategic factor with regards to growth and is committed to promoting socially and environmentally responsible development. Among the latest investments, the US integrated plants in Circleville (OH) and Inola (OK). In April 2019 the very first OraLock™ was installed on PM2 crescent former, producing premium toilet paper; since then, an accurate validation process started, taking advantage of precise statistical tools. “Clever and robust design, which allows OraLock™ to be rightfully defined as the most flexible among rigid Yankee doctors” – says Mr. Francesco Corrotti, Sofidel PM Operating Coordination Director. “Easy and quick profiling which results in an increased care to our Yankee”: this is how Mr. Alessandro Ciardetti – Soffass Via Lazzareschi Mill Mech. Maintenance Manager – underlines a couple of the important features of OraLockTM. More than one year after the installation, OraLock™ has proven to live up to expectations, confirming the great potential of this new rigid doctoring system, capable of offering a series of measurable advantages which confirm its ability to optimize the production process.

Oradoc s.r.l.

For more than 30 years ORADOC has been representing a benchmark in doctoring systems, a history of excellence dedicated to creating new standards. ORADOC has developed specific technical solutions tailored for different production and process needs, in order to provide its customers with tangible and measurable results. ORADOC offers integrated systems able to meet the ever-changing needs of paper and tissue complex markets, thus guaranteeing high-performance products. ORADOC can boast an in-depth knowledge of the productive process and this is the essential requirement to be able to offer its customers the best choice of materials and the best doctoring solutions. Respect, team-working and efficiency are the key values which better describe Oradoc.

The common concept design of creping blade holders has always narrowed down the choices to just two main possibilities: rigid or flexible, both with their strengths and weaknesses. But what if a rigid doctoring system could boast the profiling advantages of a flexible one? Worldwide known for its self-profiling flexible blade holders, Oradoc has recently patented a brand-new, innovative doctoring system that deserves a unique place in creping history: OraLockTM, the perfect fit for all Yankee cylinders.

“As a company we have ventured into a segment in which we had never thought of deepening the application possibilities, so far. Our installations in the world are mainly flexible, but with this new product we want to consolidate our presence also in the rigid market with a disruptive solution” – says Mr. Maurizio Tomei, Oradoc Sales and Customer Care Manager.

A wide range of integrated solutions for the tissue industry, specifically conceived to meet the needs of each production line

It took more than 3 years of R&D activities carried out by Oradoc engineers, including scale and full-size prototypes, off-line static tests and continuously running machine monitoring, to conceive, design and test this state-of-the-art creping solution.

“Our research and development department is rightfully proud to have achieved a great result in coming up with such a groundbreaking blade holder – explains Mr. Andrea Orlandini, Oradoc Operations Manager. We’ve worked on this system a lot and the final product really meets our expectations and – what’s even most important – it represents the perfect answer to our customers’ needs!”. But no innovation is worth adopting until its usefulness is proven: Oradoc found in Sofidel the perfect partner to be involved in this ambitious project, as Sofidel allowed for the pilot installation to take place in its “Soffass Cartiera Via Giuseppe Lazzareschi” plant (formerly known as Delicarta Paper Mill).

The Sofidel Group is one of the leading manufacturers of paper for hygienic and domestic use worldwide. Established in 1966, the Group has subsidiaries in 12 countries – Italy, Spain, the UK, France, Belgium, Germany, Sweden, Poland, Hungary, Greece, Romania and the USA, with more than 6,000 employees, net sales of 1,919 million Euros (2019) and a production capacity of over one million tons per year (1,308,000 tons in 2019). A member of the UN Global Compact and the international WWF Climate Savers program, the Sofidel Group considers sustainability a strategic factor with regards to growth and is committed to promoting socially and environmentally responsible development. Among the latest investments, the US integrated plants in Circleville (OH) and Inola (OK). In April 2019 the very first OraLock™ was installed on PM2 crescent former, producing premium toilet paper; since then, an accurate validation process started, taking advantage of precise statistical tools. “Clever and robust design, which allows OraLock™ to be rightfully defined as the most flexible among rigid Yankee doctors” – says Mr. Francesco Corrotti, Sofidel PM Operating Coordination Director. “Easy and quick profiling which results in an increased care to our Yankee”: this is how Mr. Alessandro Ciardetti – Soffass Via Lazzareschi Mill Mech. Maintenance Manager – underlines a couple of the important features of OraLockTM. More than one year after the installation, OraLock™ has proven to live up to expectations, confirming the great potential of this new rigid doctoring system, capable of offering a series of measurable advantages which confirm its ability to optimize the production process.

Products

CAD systems, Calender cylinders, Calenders, Cleaners, Consultancy services, Creping blades, Creping cylinders, Cylinders, Dewatering machines, Doctor holding devices, Doctor motors, Doctors and doctor blades, Drying cylinders, Laboratory for analysis and measures, Maintenance, Measuring and control equipments, Measuring instruments and systems, Non-woven machines, Paper machines, Presses, Process controls for paper machines, Reelers, Software, Spare parts, Suction press rolls, Suction rolls, Technical service, Testing equipments, Topformers, Training Courses, Yankee cylinders .