Another important step further for our company, within the Energy Saving and High-Tech innovative solutions. Fulfilling our mission voted to the “Spirit of Improving”, we applied the know-how achieved along the Tunnel Boring Machines experience to our massive production drives. The T.B.M. environment is one of the toughest and heaviest ever: narrow spaces, high vibrations and temperatures due to eight 400kw motors drilling the earth, pushed our Team on developing an extraordinary robust, reliable product fit-to. Actually this can be a good parallel to the paper mill environment. That’s why we are much confident to encourage this philosophy on paper mill applications. An high technological driven solution achieved along our history, over forty years of continuous improvement, experience and applications in the paper mill: by far the best in terms of energy consumptions, minor spaces and performances.

SAEL and innovation, the technological gap:

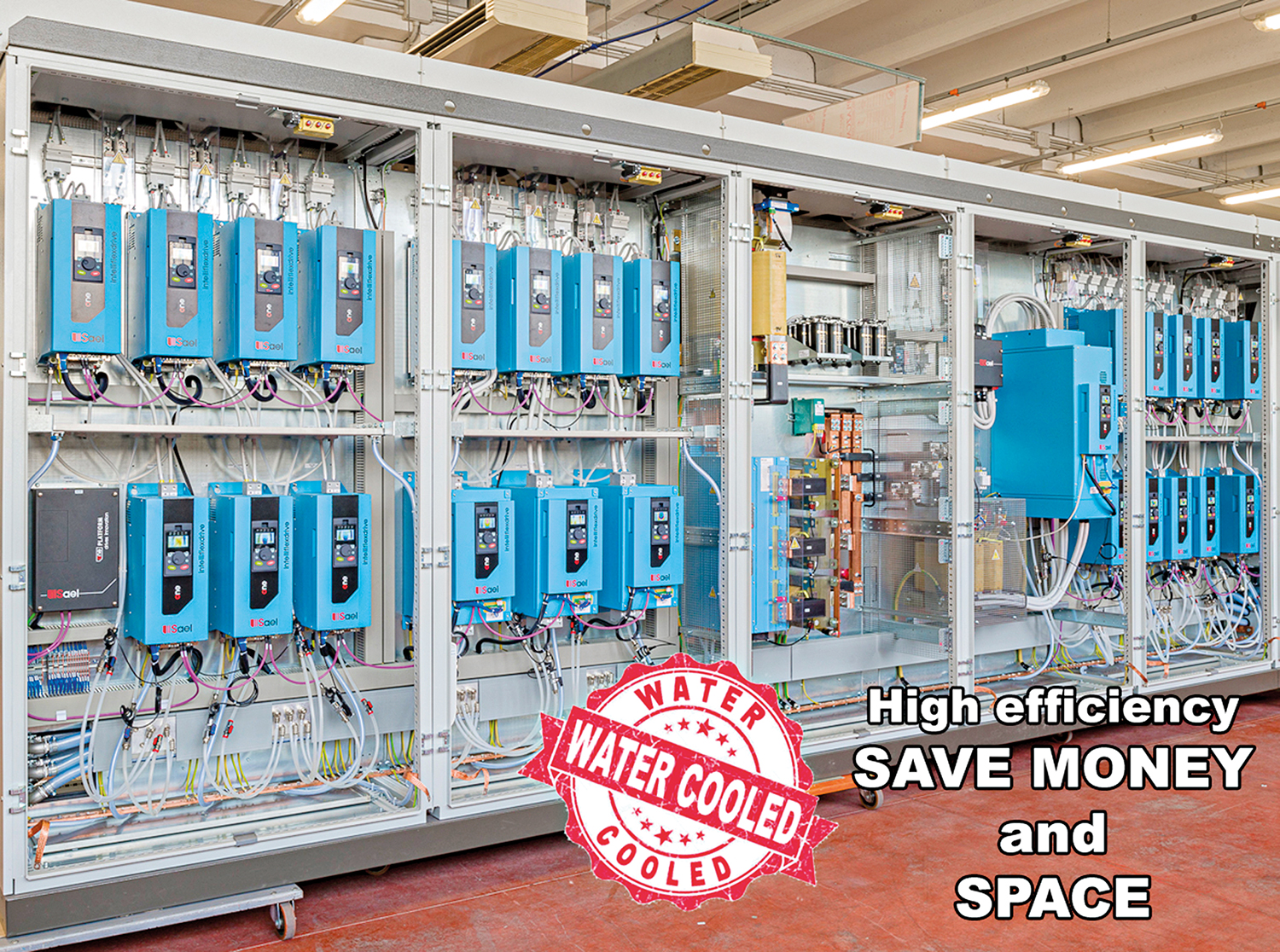

THE PLAFORM ONE DRIVE LIQUID-COOLED

The water-cooled inverter solution, without traditional tangential fans (one each inverter), does not require any electrical cabinet forced ventilation – formerly mounted on every single cabinet door. This has a big advantage in term of no more dust, humidity, acidity and pollution inside the cabinet, as much as a longer life of the entire electro-mechanical and electronic components. The good results achieved along the experience, offer great benefit to the paper mill: higher efficiency, energy and consumption savings, top technology and no conditioners maintenance. Actually the warm water can be used for the stock preparation.

Today, main groups like SACI, SONOCO, FORNACI and ERMOLLI are using our water-cooled technology. Moreover, due to cost effectiveness and support, they become our best supporters for this application.

SAEL, the spirit of improving

From our last job at Cartiere Fornaci

Mr. Edoardo Caprioli, the technical manager of the paper mill said: “The new water ONE Drive – integrated into the SAEL DCS in Drive – immediately raised up the efficiency and the machine drivability. The fine tuning made by the SAEL technicians has minimized the mechanical interferences. The great flexibility of this system perfectly fits to the production needs, as well as the existing parts of the plant. The good engineering job allowed a quick start up: actually, saving two days vs. the plan. The DCS in Drive features the trend functions, the data recording and their benchmarking: helpful functions to a better process management. The remote machine control by the IWSA – Internet World Sael Assistance – completes the package. I want to personally thanks all the paper mill team group: from the ownership to the management, till the SAEL team for their commitment and shift capabilities. Together we achieved an outstanding result!”.

Customer first and custom solutions is our philosophy: our mindset

SAEL srl

The paper production has three key words: quality, efficiency, 24/24 continuous production. A committed and specialized Team focused on innovative solutions development: from the revamping of the existing machines up to the new production lines

Custom and Flexible solutions: Systems and friendly user interfaces for any production stage. A long experience over the years allows the full integration between the most popular branded components – Inverters, Plc and the ONE Drives SAEL born for paper industry

SAEL DRIVES: A STEP BEYOND

After having equipped the inverters with film capacitors and ONE Regulation Board is time for liquid cooling. The advantages: spaces, no fans on drive, no conditioning areas, absence of dust contamination in acid environment and an important energy saving.

Another important step further for our company, within the Energy Saving and High-Tech innovative solutions. Fulfilling our mission voted to the “Spirit of Improving”, we applied the know-how achieved along the Tunnel Boring Machines experience to our massive production drives. The T.B.M. environment is one of the toughest and heaviest ever: narrow spaces, high vibrations and temperatures due to eight 400kw motors drilling the earth, pushed our Team on developing an extraordinary robust, reliable product fit-to. Actually this can be a good parallel to the paper mill environment. That’s why we are much confident to encourage this philosophy on paper mill applications. An high technological driven solution achieved along our history, over forty years of continuous improvement, experience and applications in the paper mill: by far the best in terms of energy consumptions, minor spaces and performances.

SAEL and innovation, the technological gap:

THE PLAFORM ONE DRIVE LIQUID-COOLED

The water-cooled inverter solution, without traditional tangential fans (one each inverter), does not require any electrical cabinet forced ventilation – formerly mounted on every single cabinet door. This has a big advantage in term of no more dust, humidity, acidity and pollution inside the cabinet, as much as a longer life of the entire electro-mechanical and electronic components. The good results achieved along the experience, offer great benefit to the paper mill: higher efficiency, energy and consumption savings, top technology and no conditioners maintenance. Actually the warm water can be used for the stock preparation.

Today, main groups like SACI, SONOCO, FORNACI and ERMOLLI are using our water-cooled technology. Moreover, due to cost effectiveness and support, they become our best supporters for this application.

SAEL, the spirit of improving

From our last job at Cartiere Fornaci

Mr. Edoardo Caprioli, the technical manager of the paper mill said: “The new water ONE Drive – integrated into the SAEL DCS in Drive – immediately raised up the efficiency and the machine drivability. The fine tuning made by the SAEL technicians has minimized the mechanical interferences. The great flexibility of this system perfectly fits to the production needs, as well as the existing parts of the plant. The good engineering job allowed a quick start up: actually, saving two days vs. the plan. The DCS in Drive features the trend functions, the data recording and their benchmarking: helpful functions to a better process management. The remote machine control by the IWSA – Internet World Sael Assistance – completes the package. I want to personally thanks all the paper mill team group: from the ownership to the management, till the SAEL team for their commitment and shift capabilities. Together we achieved an outstanding result!”.

Customer first and custom solutions is our philosophy: our mindset

Products

AC motors, AC-DC drives, Automation systems, Calender drives, Coating machine drives, Control and switch panels, Cutter drives, DC motors, Electrical drives, Electrical equipments, Electrical motors, Grinder drives, Meters equipments, Paper machine drives, Winder drives .