When you talk about companies that started up in a garage and were later extremely successful, you can’t help thinking about Microsoft, Apple and co. But there are also many captains of industry outside the internet economy who have worked their way up from modest beginnings with courage and far-sightedness. And you don’t necessarily have to travel as far as Silicon Valley to find them. A visit to Hungary is worth it too. To Vajda Papír for example. The company was founded in 1999 in a back yard with only one machine producing toilet tissue. Today, over twenty years later, it is the market leader in Hungary, producing over 100,000 tons of sanitary paper, for napkins, toilet tissue and paper towels for example. ANDRITZ has accompanied this history of growth as a technology supplier and system partner in the past few years. Within 15 months, a complete paper production line was delivered, installed and started up by the end of 2018.

PrimeLine paper and board machines are flexible and reliable machines that incorporate both experience and innovation

On an area of 26,000 square meters, around 30,000 tons of sanitary paper are produced every year in Dunaföldvár, and not just for consumers. By systematically extending the value chain and expanding production to include extra-strong and highly absorbent paper, Vajda Papír tapped into new target groups: hotels, restaurants and cafes. “We were well aware that we needed a specific paper quality for these customers that we could not purchase on the market in sufficient quantities – says founder and Managing Director Attila Vajda. The obvious thing to do was to begin producing paper here locally paper of very high quality”.

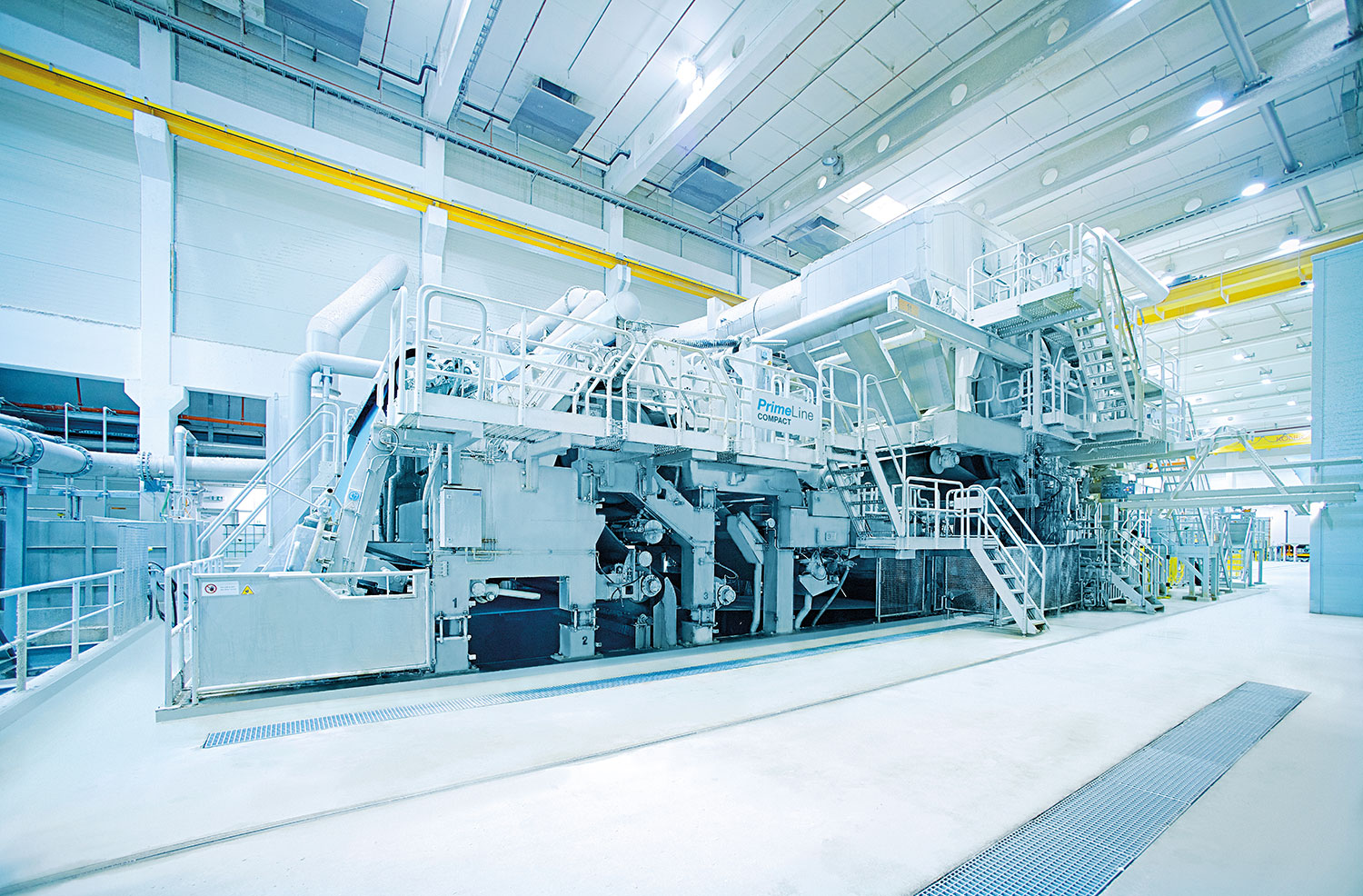

Vajda Papír found the right partner for this in ANDRITZ: the company designed and supplied the complete tissue production line, provided comprehensive support during start-up and, thanks not least to digital solutions, is always available for advice and troubleshooting during operations. The scope of supply comprises a modern, spatially compact PrimeLineCOMPACT VI tissue machine with a steel yankee and a shoe press. In addition it includes a complete stock preparation system with pumps, automation, electrical equipment, all peripheral units and the relevant ancillary services. The machine was also fitted with comprehensive sensor technology that allows to gain a detailed inside view of current operating conditions and behavior. “We deliberately sought out a lean overall package that is state-of-the-art.

The line provides the right response to our needs and those of our customers – says Attila Vajda. We are particularly pleased with its efficiency, paper quality and comparatively low energy consumption”.

Economical, efficient and connected

From a technological point of view, efficiency and connectivity are what stand out in Dunaföldvár: for example, the ANDRITZ PrimePress XT Evo shoe press dewaters the paper web very gently but also very thoroughly. By doing so, it achieves a higher dry content than conventional presses. Due to the special design of the press and the reduced need for thermal drying, energy is saved. Specifically, this means that energy savings of up to 20 percent are possible under optimum operating conditions in combination with the ANDRITZ PrimeDry Steel Yankee. The ANDRITZ Re-Evaporation system enables additional energy savings by up to 10%. And ANDRITZ also tapped into new potential in Dunaföldvár in the digitalization sector.

“It is one of the first tissue production lines from ANDRITZ that are connected to the Metris Performance Center in Graz to enable 24-hour online support and remote control – says Michael Auer, ANDRITZ Project Manager Automation. This comprehensive and secure connectivity provides valuable support, especially in the start-up phase: The experts in the Performance Center can actively assist during start-up and ramping up of the plant by keeping an eye on all the main parameters and intervening in an advisory and controlling capacity, if necessary and requested by the customer“.

“Digitalization and artificial intelligence are very important in paper production – Attila Vajda also believes. They help operators and engineers to find the optimum plant settings speedily, circumvent problems and plan predictive maintenance. There is no alternative to comprehensive sensor technology, big data analysis and the implementation of intelligent algorithms if you want to operate efficiently. In other words, the future has already begun at Dunaföldvár”.

ANDRITZ

Recycled fiber systems for all paper grades; stock preparation and machine approach systems; Prime-Line tissue, paper and board machines; Yankee field service and Yankee life cycle management; sludge and reject handling systems; engineered wear products for complete stock preparation, e.g. screen baskets, rotors, cleaner, pulping and dewatering equipment as well as refiner plates; forming fabrics for all types of paper machines and papers, technical wire cloths for industrial applications; centrifugal pumps open or closed impellers; medium-consistency pumps and equipments, fan pumps, self-priming pumps, vortex pumps, multi-stage pumps and vertical pumps, dynamic steam and heating system.

When you talk about companies that started up in a garage and were later extremely successful, you can’t help thinking about Microsoft, Apple and co. But there are also many captains of industry outside the internet economy who have worked their way up from modest beginnings with courage and far-sightedness. And you don’t necessarily have to travel as far as Silicon Valley to find them. A visit to Hungary is worth it too. To Vajda Papír for example. The company was founded in 1999 in a back yard with only one machine producing toilet tissue. Today, over twenty years later, it is the market leader in Hungary, producing over 100,000 tons of sanitary paper, for napkins, toilet tissue and paper towels for example. ANDRITZ has accompanied this history of growth as a technology supplier and system partner in the past few years. Within 15 months, a complete paper production line was delivered, installed and started up by the end of 2018.

PrimeLine paper and board machines are flexible and reliable machines that incorporate both experience and innovation

On an area of 26,000 square meters, around 30,000 tons of sanitary paper are produced every year in Dunaföldvár, and not just for consumers. By systematically extending the value chain and expanding production to include extra-strong and highly absorbent paper, Vajda Papír tapped into new target groups: hotels, restaurants and cafes. “We were well aware that we needed a specific paper quality for these customers that we could not purchase on the market in sufficient quantities – says founder and Managing Director Attila Vajda. The obvious thing to do was to begin producing paper here locally paper of very high quality”.

Vajda Papír found the right partner for this in ANDRITZ: the company designed and supplied the complete tissue production line, provided comprehensive support during start-up and, thanks not least to digital solutions, is always available for advice and troubleshooting during operations. The scope of supply comprises a modern, spatially compact PrimeLineCOMPACT VI tissue machine with a steel yankee and a shoe press. In addition it includes a complete stock preparation system with pumps, automation, electrical equipment, all peripheral units and the relevant ancillary services. The machine was also fitted with comprehensive sensor technology that allows to gain a detailed inside view of current operating conditions and behavior. “We deliberately sought out a lean overall package that is state-of-the-art.

The line provides the right response to our needs and those of our customers – says Attila Vajda. We are particularly pleased with its efficiency, paper quality and comparatively low energy consumption”.

Economical, efficient and connected

From a technological point of view, efficiency and connectivity are what stand out in Dunaföldvár: for example, the ANDRITZ PrimePress XT Evo shoe press dewaters the paper web very gently but also very thoroughly. By doing so, it achieves a higher dry content than conventional presses. Due to the special design of the press and the reduced need for thermal drying, energy is saved. Specifically, this means that energy savings of up to 20 percent are possible under optimum operating conditions in combination with the ANDRITZ PrimeDry Steel Yankee. The ANDRITZ Re-Evaporation system enables additional energy savings by up to 10%. And ANDRITZ also tapped into new potential in Dunaföldvár in the digitalization sector.

“It is one of the first tissue production lines from ANDRITZ that are connected to the Metris Performance Center in Graz to enable 24-hour online support and remote control – says Michael Auer, ANDRITZ Project Manager Automation. This comprehensive and secure connectivity provides valuable support, especially in the start-up phase: The experts in the Performance Center can actively assist during start-up and ramping up of the plant by keeping an eye on all the main parameters and intervening in an advisory and controlling capacity, if necessary and requested by the customer“.

“Digitalization and artificial intelligence are very important in paper production – Attila Vajda also believes. They help operators and engineers to find the optimum plant settings speedily, circumvent problems and plan predictive maintenance. There is no alternative to comprehensive sensor technology, big data analysis and the implementation of intelligent algorithms if you want to operate efficiently. In other words, the future has already begun at Dunaföldvár”.

Products

Aeration and deaeration plants, Air conditioning plants, Air heaters, Assembling, Automation systems, Bleaching plants, Calenders, Calenders revamping, Centrifugal pumps, Chemical fluid pumps, Chests, Cleaners, Cleaning systems, Coating machines and plants, Condensate plants, Control instruments and systems, Controlled wind reelers, Controllers, Conveying equipments, Conveying screws, Conveyors, Core drums, Creping cylinders, Cylinders, Deflakers, Deinking systems, Dewatering machines, Disc filters, Dispersing machines, Dissolving plants, Dosing pumps, Drum filters, Dryers and drying plants, Drying cylinders, Drying hoods, Dust extractors, Energy Saving, Exhausters, Fabric guide, Fans, Felt guide, Fiberizer, Fibre preparation systems, Fibre recovery filters, Flotations plants, Forming fabrics, Headboxes, Heat exchangers, Heat recovery systems, High density cleaners, High pressure pumps, Hydrocyclones, Maintenance, Measuring and control equipments, Measuring instruments and systems, Mechanical seals, Medium consistence pumps, Mixers, Non-woven machines, Paper machines, Paper Mills plants, Paperboard machines, Perforated screen plates, Presses, Pressurized headboxes, Process computers control, Process controls for paper machines, Production lines, Project planning, Pulp plants, Pulp presses, Pulp pumps, Pulp washers, Pulper feeds, Pulpers, Pulpers for paper machines, Pumps, Recovery plants, Reelers, Refiner bars, Refiner controllers, Refiner disks, Refiners, Roller bearings for paper machines, Rolls, Screening machines, Screens, Screw presses, Shafts, Sludge dewatering plants, Spare parts, Standard chemical pumps, Steam and condensate systems, Stock preparation systems, Suction box bars, Suction press rolls, Suction rolls, Technical service, Thickeners, Thickening filters, Topformers, Twin wire formers, Ventilation equipments, Washing filters, Waste paper preparation systems, Yankee cylinders, Yankee hoods .