The purpose of oscillation is to improve doctoring efficiency in roll cleaning, sheet shedding and water removal. Oscillation ensures that the blade wears evenly keeping the linear pressure across the blade tip constant. Oscillation also aids in keeping the blade tip sharp, which allows for a lower operating temperature with less friction, prolonging roll life and blade life.

Bonetti’s success is based on a timely response to the needs and demands of the markets

In the past, oscillators used a pneumatic system called Air Bag Bellows Oscillator that was inexpensive but was not reliable due to jerky oscillating strokes. Most common systems today are Electro-Mechanical Oscillators which have a smooth oscillation stroke but are expensive to maintain, due to the failure of the electrical gear motor and other mechanical components. Today many papermakers are in the process of upgrading their systems with Pneumatic Doctor Oscillators.

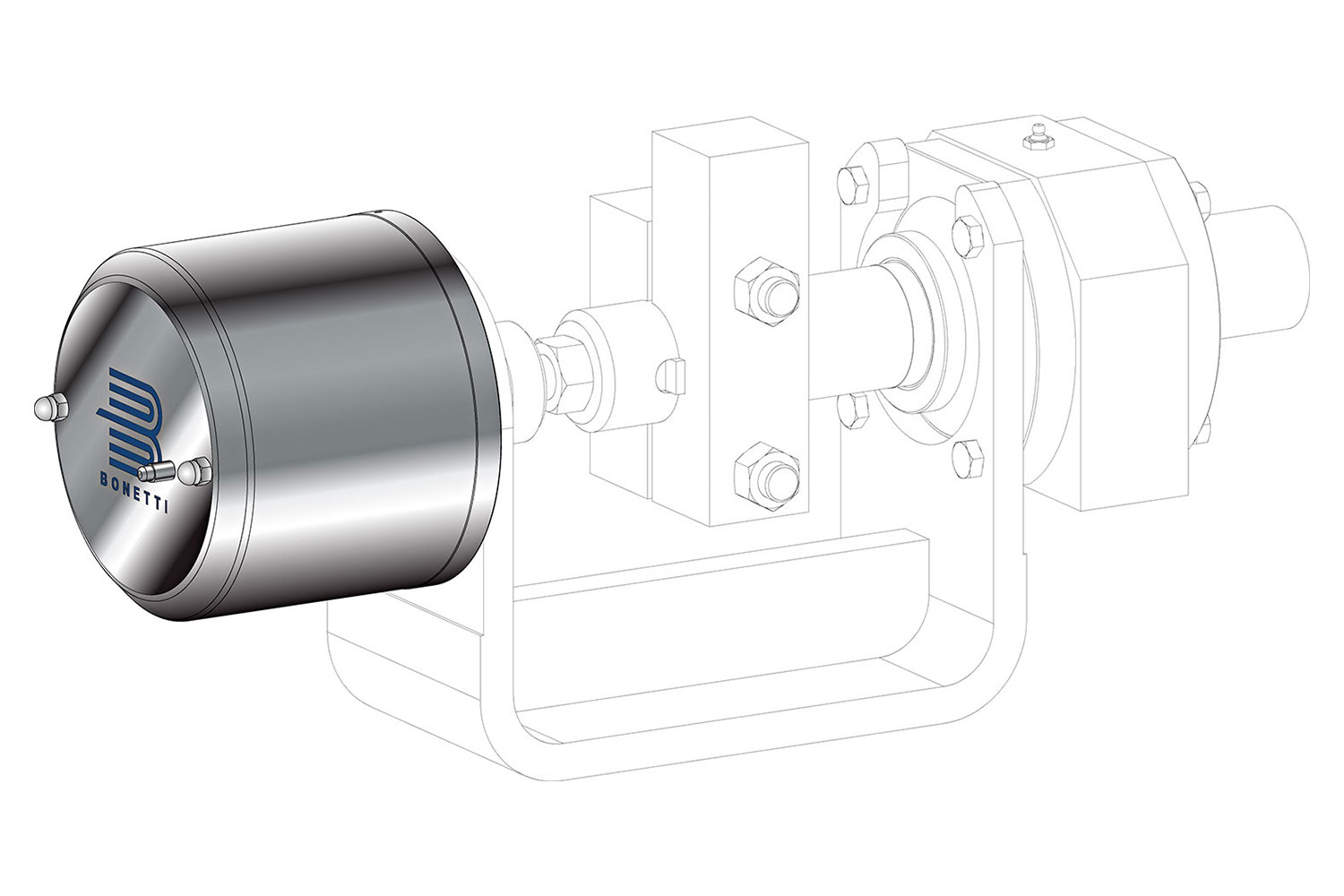

Bonetti developed a new, efficient, compact pneumatic doctor oscillator called BonMatic, which can be used in all positions of the paper machine, from the wet-end to the dry-end. Operating temperature can range from +5 °C to +150 °C. BonMatic is available in two sizes, for standard and heavy-duty applications. For each size, 3 different oscillating strokes are available: +/-5mm, +/-8 mm, +/-10 mm. Oscillating speeds can be adjusted, with thrust up to 22kN at 6 bars (working range is from 2 to 10 bar). Heavy-duty, Double Pneumatic Oscillators are designed for wide machines and particularly suitable for big Tissue Machines in the Creping, Take Off and Cleaning positions.

BonMatic is very compact and smooth in its movements and requires little maintenance.

The system does not require electric power – only a single mill air source line, along with good air-filtration. No separate control cabinet is required.

Due to its stainless steel AISI 316L construction, BonMatic is strong and durable.

The system is easy to maintain, as maintenance crews typically only need to keep the oscillator air supply clean and change Viton Seals after their normal life circle. BonMatic can be easily installed and there is no need to stock multiple electrical motors with different configurations for each position of the paper machine. The BonMatic is a great way to upgrade from a static to an oscillating doctor system.

You will be pleased with its easy installation, minimal maintenance and superior performance. Simply remember to change the doctor bearings to self- aligning, reciprocating ball bearings and housing. A wide variety of different mounting flanges and couplings are available to retrofit most of the different applications on the market. At Bonetti, we are very proud to say that all the above products are Made in Bonetti.

A global partner of paper mills and paper-machine manufacturers worldwide

ANDRITZ Bonetti

Established in Italy in 1923, Bonetti SpA has been successfully supplying the pulp and paper industry since the early 60s with the most updated portfolio of doctor, coater and creping blades and with complete doctoring systems as well. To meet worldwide product demands, four state of the art manufacturing facilities in Europe and North America are supporting another three licensee manufacturing plants strategically located in key paper manufacturing Countries.

Strongly focused that “innovation drives efficient papermaking”, Bonetti sinks its roots in a far long experience, but has always based its success and phylosophy on a timely tailored response to the ever-changing needs and demands of the markets it serves. Continuous investments in R&D, in specialized and constantly trained staff, in new production machines and the spraying plant, guarantee all Paper Mills around the world to benefit of some of the best products available on the market.

Last but not least is Bonetti’s Service: complete audit and maintenance of the doctoring systems and the blades in use, supply of spare parts, special checking and monitoring tools are only some example of this important technical plus that has become over the years an appreciated value added on the top of the products offered.

In 2022 Bonetti joins Andritz group becoming Andritz Bonetti and will continue to be a global competent and reliable partner of paper mills and paper-machine manufacturers worlwide.

The purpose of oscillation is to improve doctoring efficiency in roll cleaning, sheet shedding and water removal. Oscillation ensures that the blade wears evenly keeping the linear pressure across the blade tip constant. Oscillation also aids in keeping the blade tip sharp, which allows for a lower operating temperature with less friction, prolonging roll life and blade life.

Bonetti’s success is based on a timely response to the needs and demands of the markets

In the past, oscillators used a pneumatic system called Air Bag Bellows Oscillator that was inexpensive but was not reliable due to jerky oscillating strokes. Most common systems today are Electro-Mechanical Oscillators which have a smooth oscillation stroke but are expensive to maintain, due to the failure of the electrical gear motor and other mechanical components. Today many papermakers are in the process of upgrading their systems with Pneumatic Doctor Oscillators.

Bonetti developed a new, efficient, compact pneumatic doctor oscillator called BonMatic, which can be used in all positions of the paper machine, from the wet-end to the dry-end. Operating temperature can range from +5 °C to +150 °C. BonMatic is available in two sizes, for standard and heavy-duty applications. For each size, 3 different oscillating strokes are available: +/-5mm, +/-8 mm, +/-10 mm. Oscillating speeds can be adjusted, with thrust up to 22kN at 6 bars (working range is from 2 to 10 bar). Heavy-duty, Double Pneumatic Oscillators are designed for wide machines and particularly suitable for big Tissue Machines in the Creping, Take Off and Cleaning positions.

BonMatic is very compact and smooth in its movements and requires little maintenance.

The system does not require electric power – only a single mill air source line, along with good air-filtration. No separate control cabinet is required.

Due to its stainless steel AISI 316L construction, BonMatic is strong and durable.

The system is easy to maintain, as maintenance crews typically only need to keep the oscillator air supply clean and change Viton Seals after their normal life circle. BonMatic can be easily installed and there is no need to stock multiple electrical motors with different configurations for each position of the paper machine. The BonMatic is a great way to upgrade from a static to an oscillating doctor system.

You will be pleased with its easy installation, minimal maintenance and superior performance. Simply remember to change the doctor bearings to self- aligning, reciprocating ball bearings and housing. A wide variety of different mounting flanges and couplings are available to retrofit most of the different applications on the market. At Bonetti, we are very proud to say that all the above products are Made in Bonetti.

A global partner of paper mills and paper-machine manufacturers worldwide

Products

Blade holders, Coating blades, Creping blades, Doctor holding devices, Doctors and doctor blades, Laboratory for analysis and measures, Maintenance, Spare parts.