Water is used throughout the process of Papermaking. It starts right at the beginning, with the wash and transportation of the pulp, to dilution, cleaning and cooling of equipment just to name a few.

Understanding that we all need to do something about this and have a crucial role to play, Paprima Industries decided to look at what we could offer for the cleaning process on paper machines. Following extensive research and development, the company came up with revolutionary Power-Jet Cleaner.

What makes Paprima different

A decade ago, Paprima’s team looked at what was available on the market for high-pressure cleaner options, gathering comments from mills considered as industry leaders. They soon realized that there were huge gaps in the performance of those high-pressure cleaners and that the majority of them failed at one point or another.

They started their R&D program to transform the cleaning of fabrics. Everything and each step of the cleaning process were looked at, from the angle of the jet to get the most efficient cleaning method, to the evacuation of the contaminants. The Power-Jet Cleaner was born.

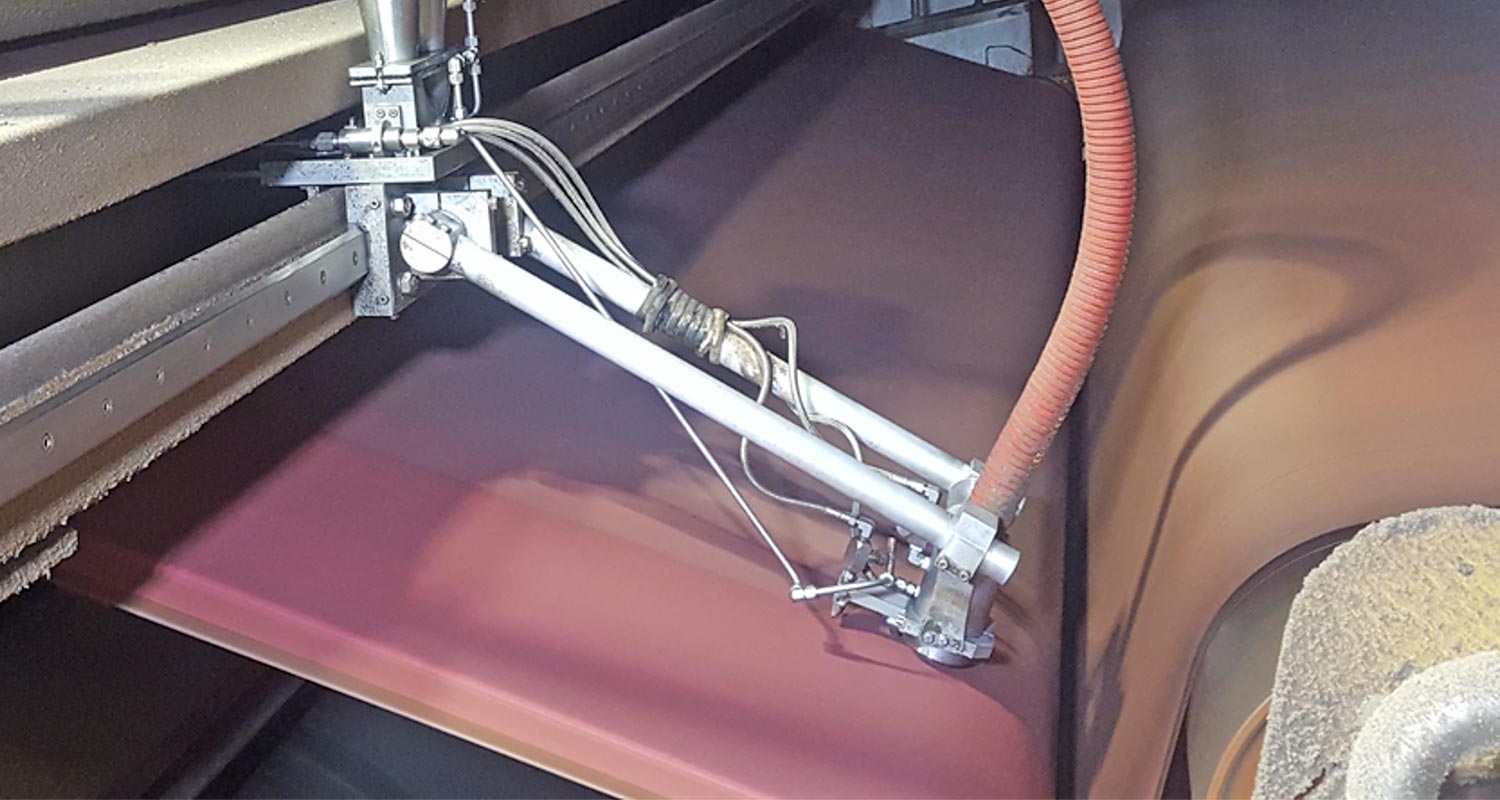

It first starts with a round head. Why design a system with a square head to, afterwards, make a transition to round piping or a flexible hose?

Square heads have corners, creating areas where contaminants can accumulate. Next was our curtain of air to control and contain the contaminants. Their curtain is less influenced by the gap between the head and the fabric, as a blade would be, and it creates the initial lift for the contaminants and the evacuation of excessive water.

Finally, their ejector, which is incorporated into the cleaning head is actually spinning everything in the evacuation tube, making the unit self-cleaning at the same time.

World leader in state-of-the-art High Pressure Water Jet Technology for the Pulp and Paper Industry

The above technology is used for wet end cleaning of fabric as well as dryer felts. However, for dryer cleaning, Paprima added another innovation.

The major problem, which is also very costly with dryer cleaners, is what to do with the air you are evacuating?

This takes up most of the space inside the piping and makes it prone to plugging. Their solution: adding cyclones to the process. They evacuate the air directly inside the dryer hood, and are now only left with evacuating water and contaminants through a small flexible hose.

The result

A perfect cleaning of the fabric, exceeding papermakers’ expectations.

What makes this process unique is that the benefit of cleanliness does not come alone. You can expect a significant reduction in sheet breaks, lower energy consumption, along with huge freshwater savings and reduced misting, amongst other benefits. For tissue machines, this technology can be used for wire and press fabrics with the same results as indicated above. In those applications, a single cleaning head will deliver water up to 2,500 PSI, through 24 linear jet nozzles with no mist created. Paprima’s Power-Jet system is a direct replacement of the existing oscillating high pressure showers, even if they incorporate a mist elimination system. The typical return on investment of a complete system is between 3 to 6 months.

It all makes sense

Paprima has been at the center of high-pressure development for the paper industry since 1986, leading the industry in water-jet turn-up and on-machine trimming systems. It was only logical for us to move into high-pressure cleaning systems, even if their operating pressures are only a fraction of our traditional cutting equipment.

of a new fabric – for the life of the fabric.

Paprima Industries Inc.

ENGINEERED WATER-JET SOLUTIONS

Paprima Industries is a prominent Canadian company. It is the world leader with state-of-the-art offerings of High Pressure Water-Jet Technology mainly for the Pulp and Paper Industry with over 30 years of experience. Paprima has the largest installed base of water-jet technology products with over 700 systems installed worldwide.

Paprima’s success is attributed to its ongoing research and development of new products merged with process knowledge and improvements of existing products to surpass customer’s expectations. Paprima is the only supplier in the world who has designed a distinct high pressure water pump and a water make up system that meets the requirements for the harsh and demanding environment of the Pulp and Paper Industry.

Water is used throughout the process of Papermaking. It starts right at the beginning, with the wash and transportation of the pulp, to dilution, cleaning and cooling of equipment just to name a few.

Understanding that we all need to do something about this and have a crucial role to play, Paprima Industries decided to look at what we could offer for the cleaning process on paper machines. Following extensive research and development, the company came up with revolutionary Power-Jet Cleaner.

What makes Paprima different

A decade ago, Paprima’s team looked at what was available on the market for high-pressure cleaner options, gathering comments from mills considered as industry leaders. They soon realized that there were huge gaps in the performance of those high-pressure cleaners and that the majority of them failed at one point or another.

They started their R&D program to transform the cleaning of fabrics. Everything and each step of the cleaning process were looked at, from the angle of the jet to get the most efficient cleaning method, to the evacuation of the contaminants. The Power-Jet Cleaner was born.

It first starts with a round head. Why design a system with a square head to, afterwards, make a transition to round piping or a flexible hose?

Square heads have corners, creating areas where contaminants can accumulate. Next was our curtain of air to control and contain the contaminants. Their curtain is less influenced by the gap between the head and the fabric, as a blade would be, and it creates the initial lift for the contaminants and the evacuation of excessive water.

Finally, their ejector, which is incorporated into the cleaning head is actually spinning everything in the evacuation tube, making the unit self-cleaning at the same time.

World leader in state-of-the-art High Pressure Water Jet Technology for the Pulp and Paper Industry

The above technology is used for wet end cleaning of fabric as well as dryer felts. However, for dryer cleaning, Paprima added another innovation.

The major problem, which is also very costly with dryer cleaners, is what to do with the air you are evacuating?

This takes up most of the space inside the piping and makes it prone to plugging. Their solution: adding cyclones to the process. They evacuate the air directly inside the dryer hood, and are now only left with evacuating water and contaminants through a small flexible hose.

The result

A perfect cleaning of the fabric, exceeding papermakers’ expectations.

What makes this process unique is that the benefit of cleanliness does not come alone. You can expect a significant reduction in sheet breaks, lower energy consumption, along with huge freshwater savings and reduced misting, amongst other benefits. For tissue machines, this technology can be used for wire and press fabrics with the same results as indicated above. In those applications, a single cleaning head will deliver water up to 2,500 PSI, through 24 linear jet nozzles with no mist created. Paprima’s Power-Jet system is a direct replacement of the existing oscillating high pressure showers, even if they incorporate a mist elimination system. The typical return on investment of a complete system is between 3 to 6 months.

It all makes sense

Paprima has been at the center of high-pressure development for the paper industry since 1986, leading the industry in water-jet turn-up and on-machine trimming systems. It was only logical for us to move into high-pressure cleaning systems, even if their operating pressures are only a fraction of our traditional cutting equipment.

of a new fabric – for the life of the fabric.

Products

Cleaners, High pressure pumps, Reel Cutters, Tail Cutters.