Over the years we’ve helped numerous customers improve their creping process, taking a comprehensive approach that spans from the blades to the doctoring equipment, them being both part of the current product portfolio. The main areas where the company focused its efforts have been the sheet quality improvement, the increase of the overall efficiency of the tissue machine and the reduction of its operating costs. The approach is diversified and tailored to the specific demands of the customer and Bonetti has been therefore bringing to the industry new tools and new products.

A good example of two new tools are the BonVibes, the new vibration monitoring system (Fig.1), and the BonTwin, the double-doctor system for the press roll (Fig. 2). BonVibes is used in the Tissue Industry to monitor the status of the cleaning and creping doctors of the Yankee dryer.

Now in the third generation of family ownership, Bonetti has been and will continue to be a global partner of paper mills and paper-machine manufacturers

By monitoring and analyzing the detected vibrations, BonVibes’ software informs the tissue maker on the correct timing to change the blades, thus reducing at a minimum the risk of chatter marks formation. Main goals of the BonVibes are: protection of the Yankee dryer surface; real time monitoring and alarming; historical Data trending. BonVibes has an intuitive and user-friendly operator interface. Two versions are available, with one or two acquisition channels.

BonTwin is a double-doctor system especially designed to improve dewatering of the press rolls in Tissue machines. Features & Benefits of the BonTwin double doctor are: improved dewatering of the press, reducing the rewetting in the Nip; improved press efficiency; increased dryness, with consequent reduction of the energy required to dry the sheet; uniform moisture profile; improved cleanness of the press; increased life of the press; increased life of the felt; reduction of the numbers of breaks.

Global partner of paper mills and paper machines

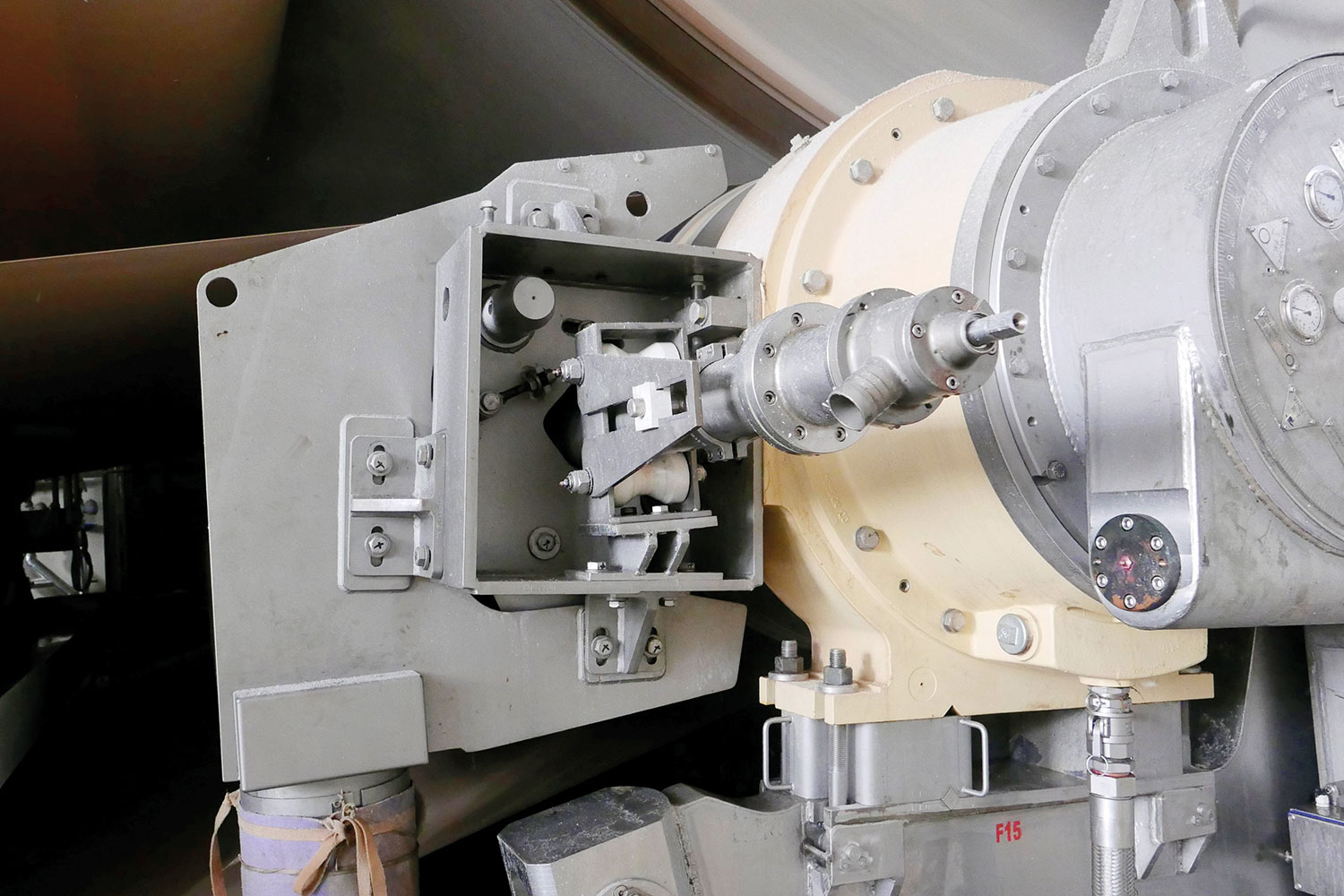

Bonetti is a worldwide leader in the supply of doctoring systems (Fig. 3) and blades (Fig. 4).

The portfolio offers a complete range of creping, coating and cleaning blades, in various materials and sizes. Focusing on the creping process, it offers two different types of tip coated creping blades: the MIZAR (Chrome Oxide) and SIRIUS (Chrome Carbide) blades. When compared to traditional carbon steel blades, they offer extended lifetime and greatly improve the softness of the sheet. These two blade qualities complete each other: whereas the MIZAR offers the longest possible lifetime, the SIRIUS, while sacrificing a small amount of lifetime, allows a smoother blade start-up, they are not prone to chipping and can be machined with sharper angles suitable for Super Soft tissue grades. Bonetti’s specialists can supply a complete audit of the doctoring systems and the blades in use. For doctoring systems the audit includes a geometric check of the mechanical condition of the doctors.

For blades, the audit includes a check of all the blades used as well as an analysis of both existing wear and of wear pattern. The technical and sales team can offer all necessary information and assist you in the implementation of your machine to keep operation running at peak performance.

Bonetti’s success has always been based on a timely response to the needs and demands of the markets it serves

ANDRITZ Bonetti

Established in Italy in 1923, Bonetti SpA has been successfully supplying the pulp and paper industry since the early 60s with the most updated portfolio of doctor, coater and creping blades and with complete doctoring systems as well. To meet worldwide product demands, four state of the art manufacturing facilities in Europe and North America are supporting another three licensee manufacturing plants strategically located in key paper manufacturing Countries.

Strongly focused that “innovation drives efficient papermaking”, Bonetti sinks its roots in a far long experience, but has always based its success and phylosophy on a timely tailored response to the ever-changing needs and demands of the markets it serves. Continuous investments in R&D, in specialized and constantly trained staff, in new production machines and the spraying plant, guarantee all Paper Mills around the world to benefit of some of the best products available on the market.

Last but not least is Bonetti’s Service: complete audit and maintenance of the doctoring systems and the blades in use, supply of spare parts, special checking and monitoring tools are only some example of this important technical plus that has become over the years an appreciated value added on the top of the products offered.

In 2022 Bonetti joins Andritz group becoming Andritz Bonetti and will continue to be a global competent and reliable partner of paper mills and paper-machine manufacturers worlwide.

Over the years we’ve helped numerous customers improve their creping process, taking a comprehensive approach that spans from the blades to the doctoring equipment, them being both part of the current product portfolio. The main areas where the company focused its efforts have been the sheet quality improvement, the increase of the overall efficiency of the tissue machine and the reduction of its operating costs. The approach is diversified and tailored to the specific demands of the customer and Bonetti has been therefore bringing to the industry new tools and new products.

A good example of two new tools are the BonVibes, the new vibration monitoring system (Fig.1), and the BonTwin, the double-doctor system for the press roll (Fig. 2). BonVibes is used in the Tissue Industry to monitor the status of the cleaning and creping doctors of the Yankee dryer.

Now in the third generation of family ownership, Bonetti has been and will continue to be a global partner of paper mills and paper-machine manufacturers

By monitoring and analyzing the detected vibrations, BonVibes’ software informs the tissue maker on the correct timing to change the blades, thus reducing at a minimum the risk of chatter marks formation. Main goals of the BonVibes are: protection of the Yankee dryer surface; real time monitoring and alarming; historical Data trending. BonVibes has an intuitive and user-friendly operator interface. Two versions are available, with one or two acquisition channels.

BonTwin is a double-doctor system especially designed to improve dewatering of the press rolls in Tissue machines. Features & Benefits of the BonTwin double doctor are: improved dewatering of the press, reducing the rewetting in the Nip; improved press efficiency; increased dryness, with consequent reduction of the energy required to dry the sheet; uniform moisture profile; improved cleanness of the press; increased life of the press; increased life of the felt; reduction of the numbers of breaks.

Global partner of paper mills and paper machines

Bonetti is a worldwide leader in the supply of doctoring systems (Fig. 3) and blades (Fig. 4).

The portfolio offers a complete range of creping, coating and cleaning blades, in various materials and sizes. Focusing on the creping process, it offers two different types of tip coated creping blades: the MIZAR (Chrome Oxide) and SIRIUS (Chrome Carbide) blades. When compared to traditional carbon steel blades, they offer extended lifetime and greatly improve the softness of the sheet. These two blade qualities complete each other: whereas the MIZAR offers the longest possible lifetime, the SIRIUS, while sacrificing a small amount of lifetime, allows a smoother blade start-up, they are not prone to chipping and can be machined with sharper angles suitable for Super Soft tissue grades. Bonetti’s specialists can supply a complete audit of the doctoring systems and the blades in use. For doctoring systems the audit includes a geometric check of the mechanical condition of the doctors.

For blades, the audit includes a check of all the blades used as well as an analysis of both existing wear and of wear pattern. The technical and sales team can offer all necessary information and assist you in the implementation of your machine to keep operation running at peak performance.

Bonetti’s success has always been based on a timely response to the needs and demands of the markets it serves

Products

Blade holders, Coating blades, Creping blades, Doctor holding devices, Doctors and doctor blades, Laboratory for analysis and measures, Maintenance, Spare parts.