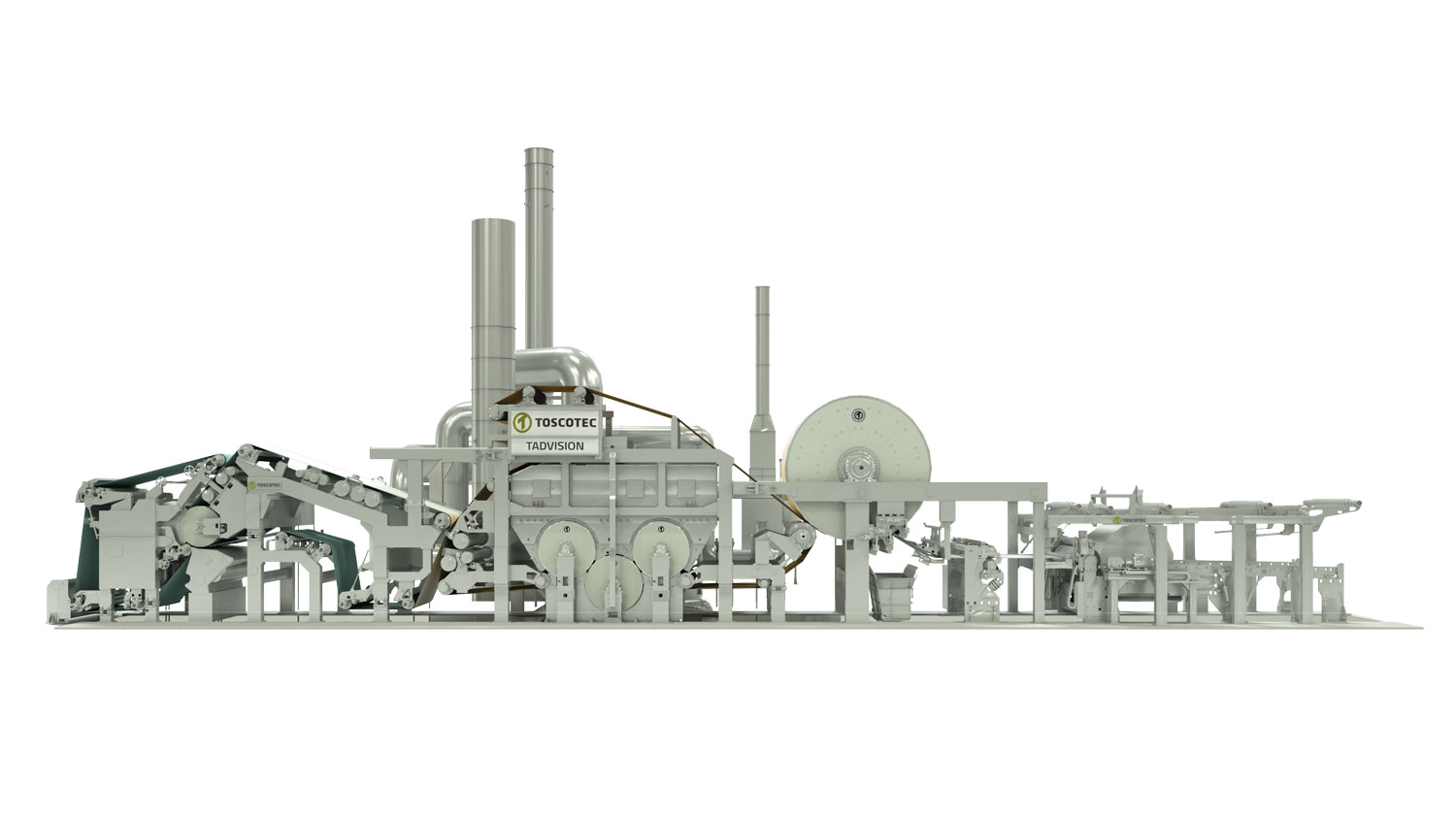

Recently, Toscotec has fully redesigned its TAD machine to achieve superior tissue properties (primarily bulk and absorbency) and outstanding results in energy consumption.

Drawing on the experience of its successful installation in the U.S. market in 2004, the new TADVISION® machine ensures highly improved runnability and machine efficiency.

Toscotec’s design fully exploits the specific features of the Through Air Drying process, in order to capitalize on its unparalleled paper quality. The drying process of the TAD section is by nature very uneven and depends on the fiber web’s moisture content and consequent air permeability, because the hot airflow tends to penetrate more and therefore better dry the areas with lower water content and higher permeability.

Excellence in technology at the service of the paper industry

TADVISION® ensures optimal Through Air Drying uniformity on its longer drying path, along which the paper goes throughout a unique serpentine TAD section, composed of three or five TAD drums. Because of the straight flow crossing the drums and the fiber web, the paper dries out in a uniform manner, to a level of dryness in the range of 75% to 90%, and it turns out to be perfectly structured by the full penetration of hot air going through the TAD drums. Thanks to its vertical, down-to-top airflow design, TADVISION® ensures that the air fully flows though the drums, thereby avoiding any problem connected with the deviation of incoming or outgoing flow in the drum’s axial direction. Toscotec’s detailed computational fluid dynamic analysis ensures a highly optimized airflow in the air-system ducts leading to the TAD section and Yankee hoods, in order to guarantee the expected uniformity of drying. An accurate moisture control in the TAD section contributes to deliver top dryness results.

Overall, TADVISION® ensures a more effective use of energy, bringing consumption down to 4.5-5.5 MWh/ton, a significant decrease compared to the consumption of current TAD machines, which is estimated in the range of 6.0-7.5 MWh/ton. Toscotec is continuing its energy reduction program and is committed to further reducing the overall consumption to less than 4.5 MWh/ton for a plant of the same production capability over the next few years.

Toscotec’s Tissue Division handles design and process engineering for complete plants or individual plant sections

According to the mill’s production targets, Toscotec offers two TAD solutions: TADVISION-S is designed for 2.85 m trim width and 120 tpd, TADVISION-L is designed for up to 5.6 m trim and 240 tpd. The exact configuration of TADVISION® is then tailor-made according to the specific production targets and process conditions of the paper mill, and it includes the option of installing Toscotec’s TT SYD without Yankee hoods. With respect to tissue properties, TADVISION® takes full advantage of its unique TAD serpentine design, taking structured tissue’s premium quality to a whole new level. The serpentine design allows for the proper reverse bending and stretching of the fiber web, in order to improve bulk and reduce fiber density, at a point in the first and second parts of the TAD section when the paper fibers are not too dry. This design largely enhances the structural, bulky nature of the finished product. Toscotec’s new TADVISION® machine was presented at iT’s Tissue 2018, in Lucca from June 25 through 29. The optimized control of the drying process, the increased energy efficiency, the largely reduced energy consumptions and the enhanced softness and bulk properties are the catchall advantages of Toscotec’s TADVISION® innovation. Industry professionals have expressed extremely positive feedback and great interest in this state-of-the-art technology.

Toscotec is currently completing manufacturing of its new TADVISION® at its headquarters in Marlia (Lucca) for a confidential project that is expected to start up in the first half of 2019.

Toscotec

Since its foundation in 1948, Toscotec specializes in the design and manufacture of turnkey projects, complete machines, plant rebuilds and single equipment for the tissue and paper & board industries.

Headquartered in Lucca, with affiliates and service centres in China and North America, Toscotec provides state-of-the-art technology and customized solutions to leading paper producers around the world.

Our technology aims at maximum production efficiency, reduced energy consumption and operating costs, finished products of the highest quality and respect for the environment.

From 30th April 2020, Toscotec is part of the Voith Group.

Recently, Toscotec has fully redesigned its TAD machine to achieve superior tissue properties (primarily bulk and absorbency) and outstanding results in energy consumption.

Drawing on the experience of its successful installation in the U.S. market in 2004, the new TADVISION® machine ensures highly improved runnability and machine efficiency.

Toscotec’s design fully exploits the specific features of the Through Air Drying process, in order to capitalize on its unparalleled paper quality. The drying process of the TAD section is by nature very uneven and depends on the fiber web’s moisture content and consequent air permeability, because the hot airflow tends to penetrate more and therefore better dry the areas with lower water content and higher permeability.

Excellence in technology at the service of the paper industry

TADVISION® ensures optimal Through Air Drying uniformity on its longer drying path, along which the paper goes throughout a unique serpentine TAD section, composed of three or five TAD drums. Because of the straight flow crossing the drums and the fiber web, the paper dries out in a uniform manner, to a level of dryness in the range of 75% to 90%, and it turns out to be perfectly structured by the full penetration of hot air going through the TAD drums. Thanks to its vertical, down-to-top airflow design, TADVISION® ensures that the air fully flows though the drums, thereby avoiding any problem connected with the deviation of incoming or outgoing flow in the drum’s axial direction. Toscotec’s detailed computational fluid dynamic analysis ensures a highly optimized airflow in the air-system ducts leading to the TAD section and Yankee hoods, in order to guarantee the expected uniformity of drying. An accurate moisture control in the TAD section contributes to deliver top dryness results.

Overall, TADVISION® ensures a more effective use of energy, bringing consumption down to 4.5-5.5 MWh/ton, a significant decrease compared to the consumption of current TAD machines, which is estimated in the range of 6.0-7.5 MWh/ton. Toscotec is continuing its energy reduction program and is committed to further reducing the overall consumption to less than 4.5 MWh/ton for a plant of the same production capability over the next few years.

Toscotec’s Tissue Division handles design and process engineering for complete plants or individual plant sections

According to the mill’s production targets, Toscotec offers two TAD solutions: TADVISION-S is designed for 2.85 m trim width and 120 tpd, TADVISION-L is designed for up to 5.6 m trim and 240 tpd. The exact configuration of TADVISION® is then tailor-made according to the specific production targets and process conditions of the paper mill, and it includes the option of installing Toscotec’s TT SYD without Yankee hoods. With respect to tissue properties, TADVISION® takes full advantage of its unique TAD serpentine design, taking structured tissue’s premium quality to a whole new level. The serpentine design allows for the proper reverse bending and stretching of the fiber web, in order to improve bulk and reduce fiber density, at a point in the first and second parts of the TAD section when the paper fibers are not too dry. This design largely enhances the structural, bulky nature of the finished product. Toscotec’s new TADVISION® machine was presented at iT’s Tissue 2018, in Lucca from June 25 through 29. The optimized control of the drying process, the increased energy efficiency, the largely reduced energy consumptions and the enhanced softness and bulk properties are the catchall advantages of Toscotec’s TADVISION® innovation. Industry professionals have expressed extremely positive feedback and great interest in this state-of-the-art technology.

Toscotec is currently completing manufacturing of its new TADVISION® at its headquarters in Marlia (Lucca) for a confidential project that is expected to start up in the first half of 2019.

Products

Drying cylinders, Drying hoods, Dust extractors, Energy Saving, Heat recovery systems, Paper machines, Paperboard machines, Presses, Rewinders, Spare parts, Steam and condensate systems, Stock preparation systems, Winders, Yankee cylinders, Yankee hoods .