This is something that MTorres Tissue engineers definitely have had in mind since the very first machine, reflecting such philosophy in every single detail composing the full tissue converting line. Talking about the rewinding section, the parameters that may change from product to product are definitely a relevant number and, quite often, this means a long set up time that also requires skilled maintenance staff. This lack of flexibility is, in most cases, a real limitation for the product portfolio, and forces the Customer to reduce the product variations, standardizing as much as possible the product data.

However, today’s market is more and more demanding, and usually not open to accepting any kind of strict product limitations. One of the main variables that affects product changeover is, certainly, the core diameter. As more and more Away From Home (AFH) products and consumer products are cross-linked, the first need is to have a huge variation of the core size. The second topic is the difficulty in changing from one diameter to the other. This operation, on conventional rewinders, requires significant down time and, especially, some mechanical changes that in most cases require the intervention of the maintenance staff.

Another big challenge, still deeply related to this tendency of cross-linking between consumer and AFH rolls, is the diameter of the finished products. As we can see, looking in the market shelves, products with a diameter of 200 mm are getting more and more popular, and the trend is definitely toward the larger diameter limit. This wide diameter change, if using conventional rewinders, would require separate converting lines to effectively provide these different diameters. Perforation length is another parameter that is definitely part of the game, as most of the product innovation is based on this feature.

The need to have variable perforation lengths, one significantly different than another, or, even in case of some specific applications, different perforations within the same product.

Research, development and production in the field of converting machines for the Tissue Industry

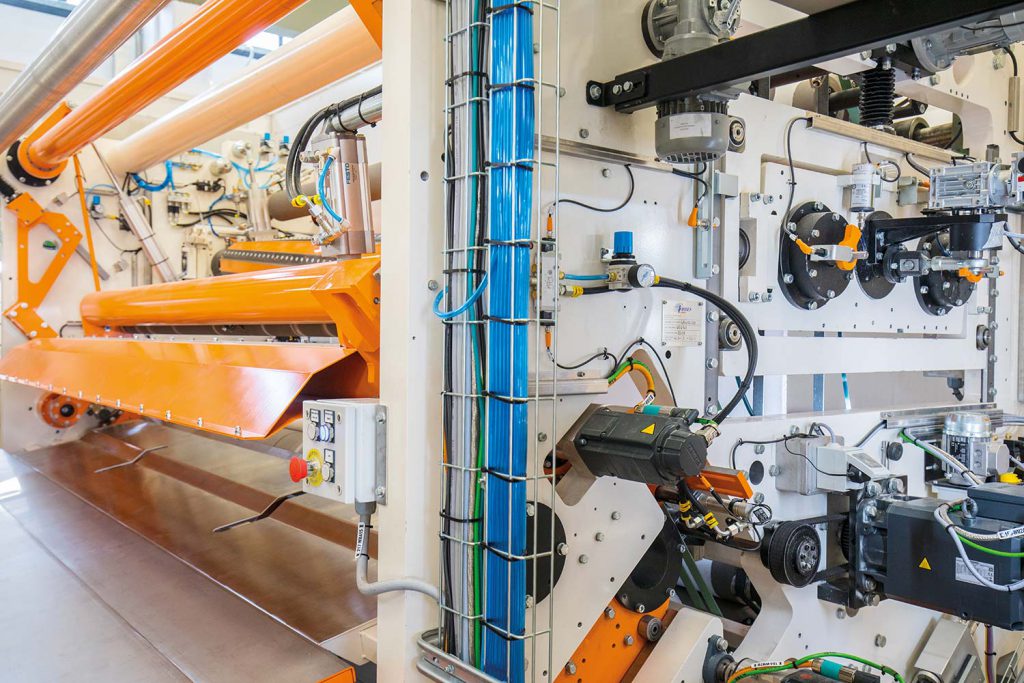

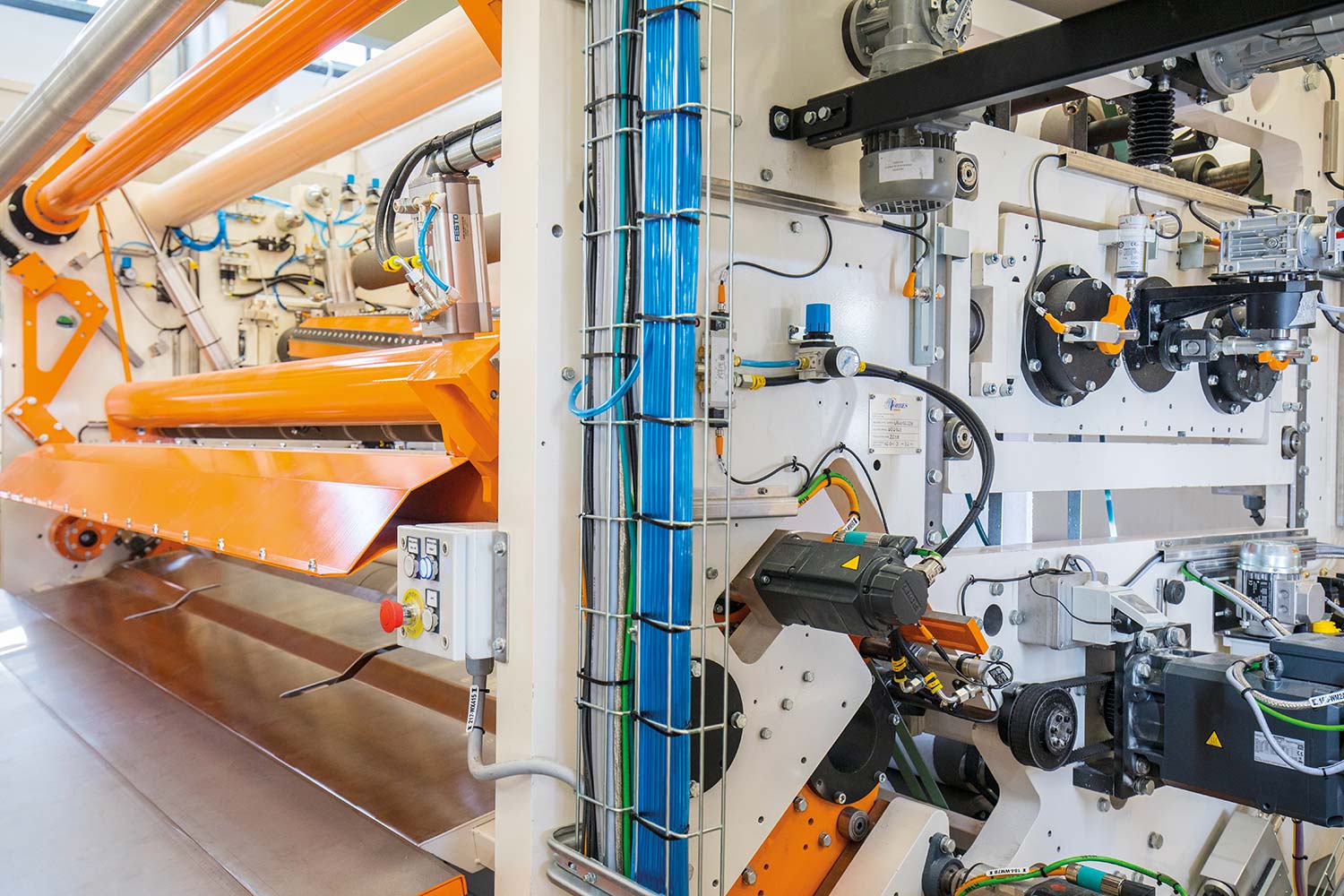

The MTorres Tissue FLEXIBLE rewinder overcame all the above-mentioned issues due to state of the art flexibility. It allows an incredible range of core size (from 20 to 85 mm) and, even more importantly, core diameter changes are achieved through an HMI. This eliminates any mechanical intervention, and requires only a few minutes of down time. In terms of product diameter, within the same rewinder, Customers have the possibility of converting small diameter logs from 90 mm, up to the extreme case of jumbo rolls with an overall diameter up to 350 mm. Again, this diameter change is controlled from the HMI, requires no tools or maintenance personnel, and is achieved in minutes.

The special construction and assembly of the perforation unit allows a wider range of perforation length and, thanks to the double perforation feature, the change from one perforation range to a completely different one becomes only a matter of different web path threading. Finally yet importantly, differently from any consumer rewinder today available on the market, FLEXIBLE rewinder is capable of producing multiple perforations and unperforated products as well with all the adjustments managed by HMI. All this flexibility has been implemented without sacrificing high-level performance of the FLEXIBLE rewinder that is capable of reaching a production speed up to 700 m/min, and an output rate of 40 logs/min.

What is the next step? Maybe producing coreless and cored rolls at the same time with an easy product changeover?

Yes and we did it. However, this is another story for another day.

Stay tuned and more to come…